Auxiliary test device

A technology of test device and cross bar, which is applied in the field of building material mechanics test device, can solve the problems of unfavorable screw anchor installation characteristics, test result error, etc., and achieve the effect of convenient recording work and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

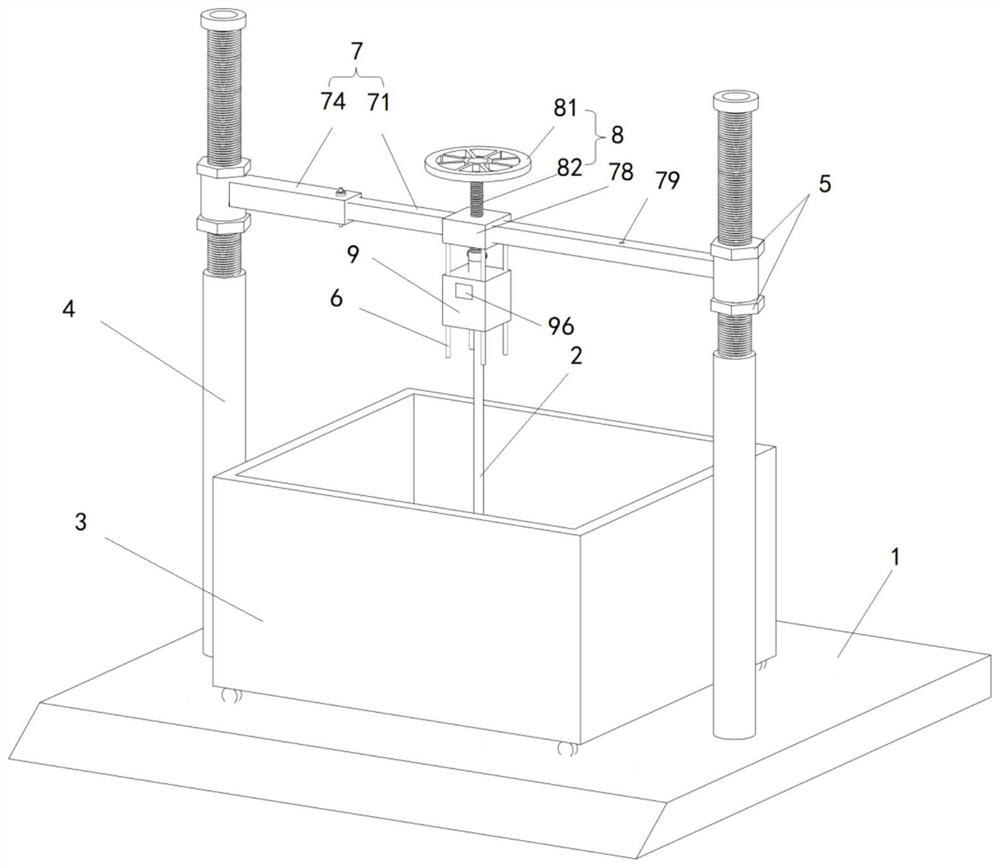

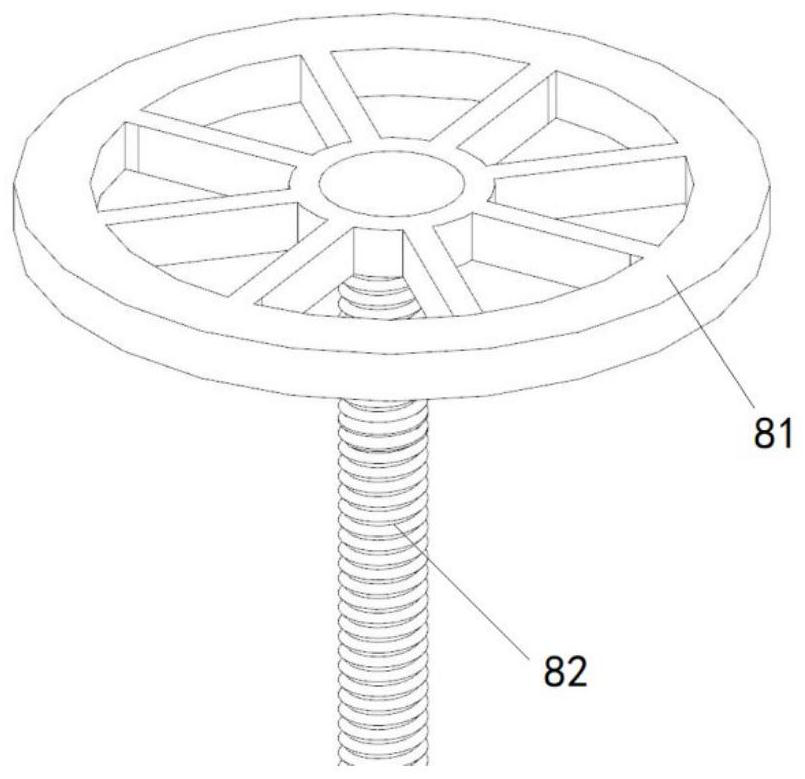

[0032] Such as figure 1 and Figure 10 As shown, the auxiliary test device includes a bracket assembly, a screw-in device, a torque sensor 9 , a plurality of limit rods 6 , a screw anchor 2 , a rotating assembly 10 , a spring dynamometer 11 , and a sandbox 3 . The bracket assembly includes a horizontal bottom plate 1, two sliding rods 4 respectively arranged at both ends of the bottom plate 1 and extending upwards, and a cross bar 7 slidably arranged on the two sliding rods 4, and the sliding rods 4 are fixed to the bottom plate 1 Connection; the screw-in device includes a hand wheel 81 and a guide rod 82 extending downward from the hand wheel 81 , and the hand wheel 81 is integrally connected with the guide rod 82 .

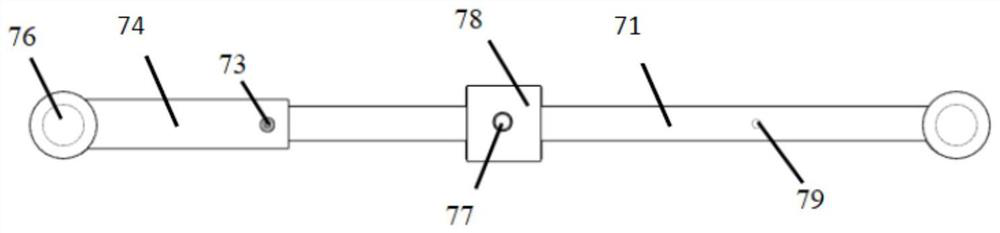

[0033] Such as Figure 2 to Figure 6 As shown, the two ends of the cross bar 7 are respectively provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com