Supporting device for track production

A technology of support device and crawler, applied in the directions of packaging, transportation and packaging, external frame, etc., can solve the problems of inability to support multiple groups of crawler synchronously, the stability of crawler support is not high, and the crawler cannot be fixed. Support range, improve the effect of support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

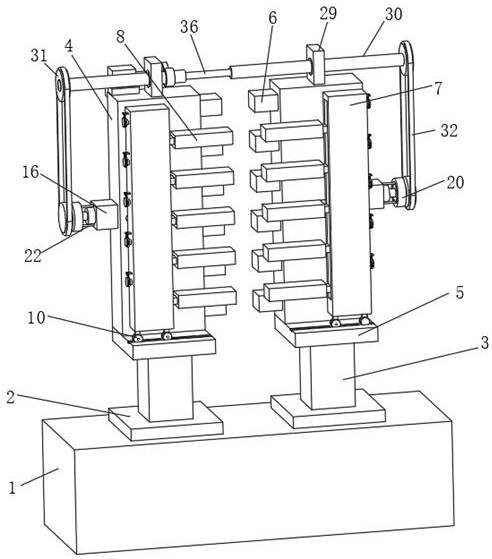

[0037] Embodiment one, by Figure 1 to Figure 10 Given, the present invention includes a support base 1, the top of the support base 1 is symmetrically provided with a support plate 2, the top of the support plate 2 is provided with a fixed column 3, and the top of the fixed column 3 is equipped with a first support column 4, One side of the bottom end of the first support column 4 is provided with a support base plate 5, and the two first support columns 4 are equipped with fixed clamping plates 6 at equal distances on the side adjacent to each other. The space between them is connected by a spacing adjustment mechanism. Through the design of the spacing adjustment mechanism, it is convenient to realize the movement of the fixed clamping plate 6, and it is convenient to adjust the distance between the two fixed clamping plates 6 in the horizontal direction according to the width of the track, thereby providing convenience for the support of the track. At the same time It is s...

Embodiment 2

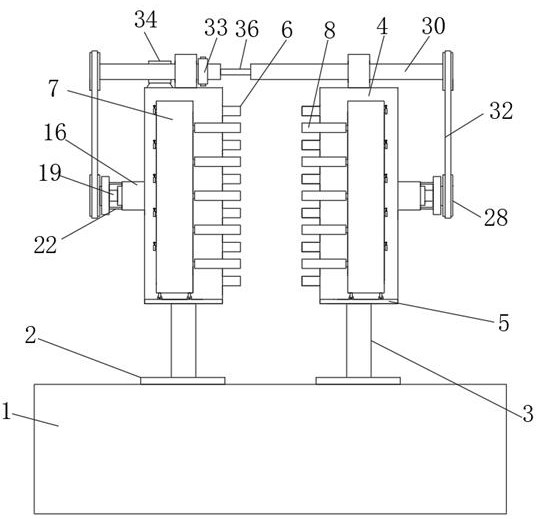

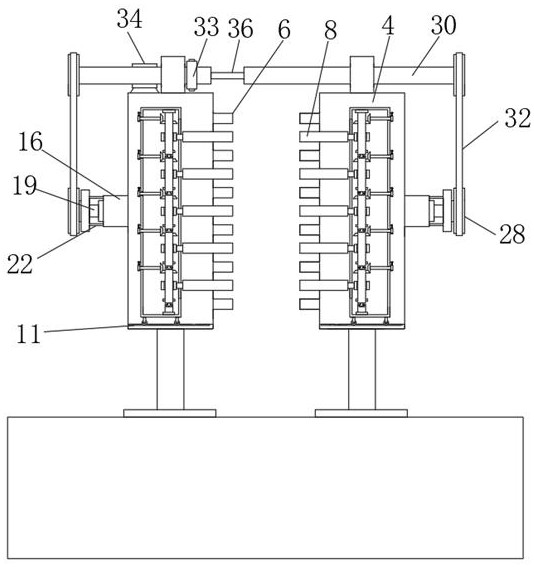

[0040] Embodiment two, on the basis of embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 10 Given, the push group includes an externally threaded rod 17, a telescopic slot 18, a rotating rod 19, a rotating knob 20, a first engaging groove 21 and a first engaging rod 22, and the inner wall of the internally threaded fixing cylinder 16 is threadedly connected with an externally threaded rod 17. The inside of the externally threaded rod 17 is provided with a telescopic groove 18, and the inside of the telescopic groove 18 is slidably connected with a rotating rod 19. One end of the rotating rod 19 extends to the outside of the externally threaded rod 17, and one end of the rotating rod 19 is located in the first The rotating knob 20 on the outside of the support column 4 is connected. One side of the internally threaded fixed cylinder 16 is symmetrically provided with a first connecting rod 22, and the inside of the rotating k...

Embodiment 3

[0042] Embodiment three, on the basis of embodiment one, by Figure 4 Given, the moving part includes a first slot 25 and a first push rod 26, and the sides of the two first support columns 4 close to the second support column 7 are provided with first openings communicating with the first receiving grooves 59. Slot 25, the inside of the first slot 25 runs through a first push rod 26 connected to the side wall of the second support column 7, and one end of the first push rod 26 is fixedly connected with the outer wall of the external threaded rod 17;

[0043] When the fixed clamping plate 6 moves horizontally, since the externally threaded rod 17 is connected with the second support column 7 through the first push rod 26, the movement of the externally threaded rod 17 will drive the first push rod 26 to move in the first groove. The inner wall of 25 slides, and then the first push rod 26 will push the second support column 7 to move on one side of the first support column 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com