Hot pot condiment stir-frying silica gel cutter

A technology of hot pot ingredients and knives, which is applied in the field of silicone knives for frying hot pot ingredients. It can solve the problems of increasing fine slag in hot pot bottom ingredients, reducing raw material breakage, and affecting the taste of food, and achieves the effects of improving efficiency, heating evenly, and fully stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

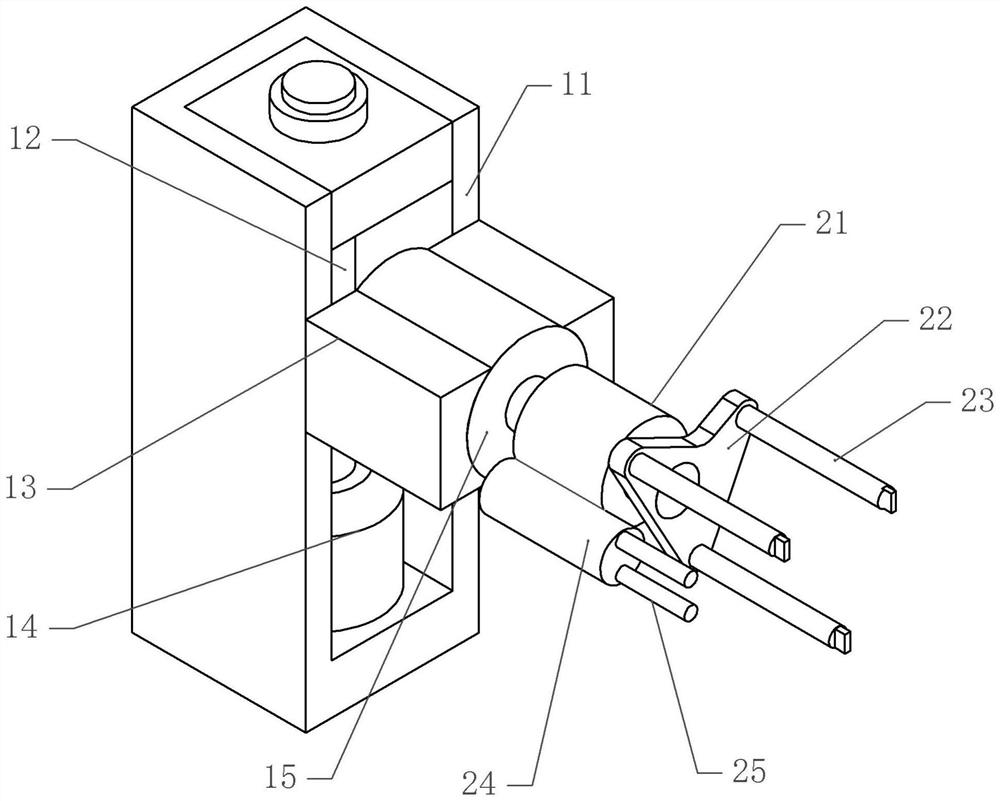

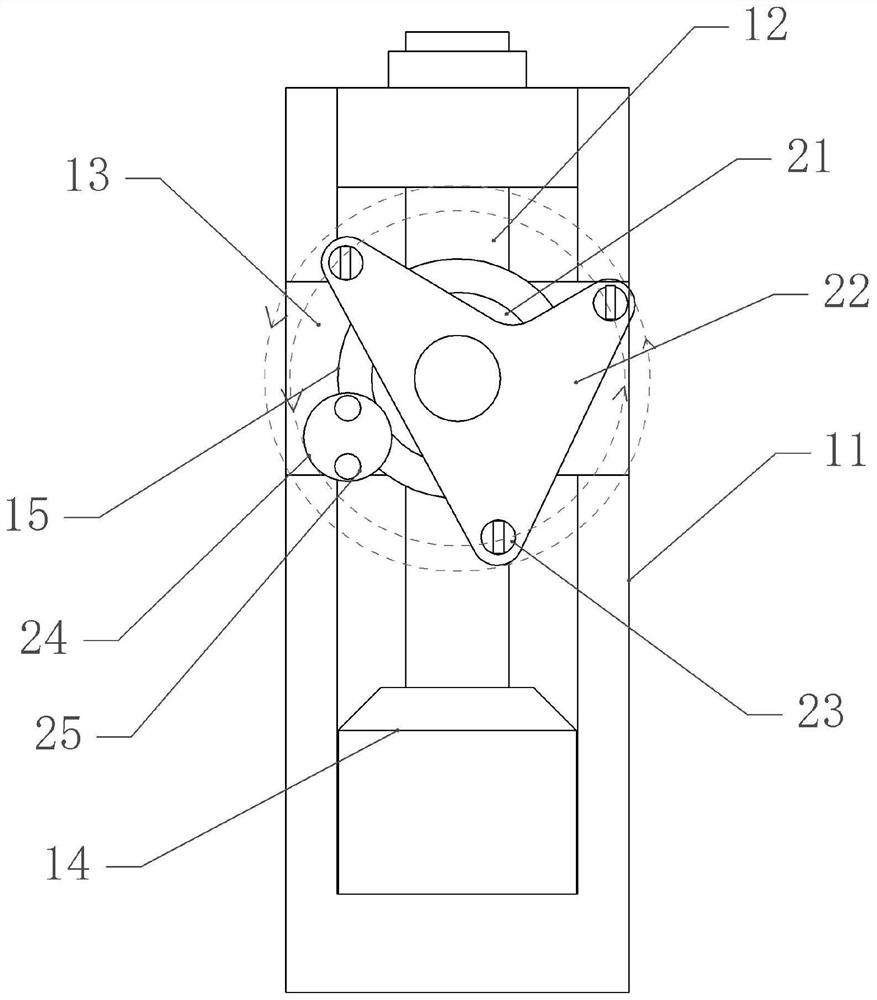

[0040] Basic as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 As shown, a silicone tool for frying hot pot ingredients includes a support base 11 and a power part installed on the support base 11. The power part is a drive motor 14, and the output shaft of the drive motor 14 is coaxially fixedly connected with a lead screw 12. The nut seat of the lead screw 12 is fixedly connected with a base 13 by bolts, and the base 13 is vertically slidably connected with the support base 11 .

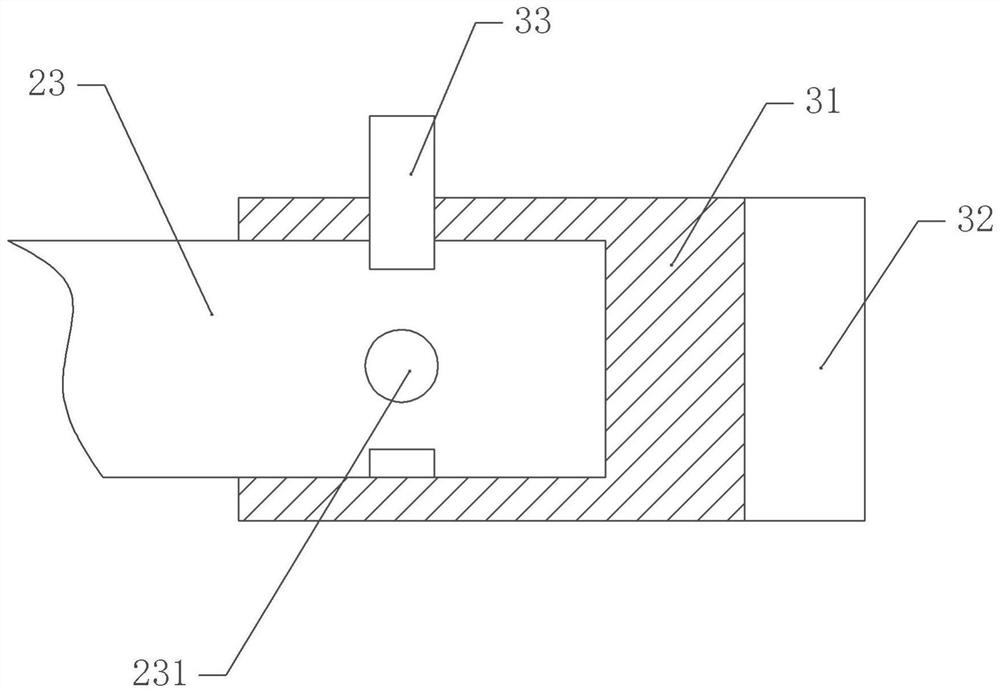

[0041]Bolts on the base 13 are fixedly connected with a driver, the driver is a single-phase motor 15, the output shaft of the single-phase motor 15 is coaxially fixedly connected with a circular support plate, and the side wall of the support plate is fixedly connected with a sub-plate 24 , the auxiliary plate 24 is fixedly connected with a number of second rotating shafts 25, the output shaft of the single-phase motor 15 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com