Batching system for recycled concrete

A technology of recycled concrete and batching system, which is applied in batching storage, mixing operation control, clay preparation device, etc., can solve the problems of cost waste and unusable recycled concrete, and achieve the effect of improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

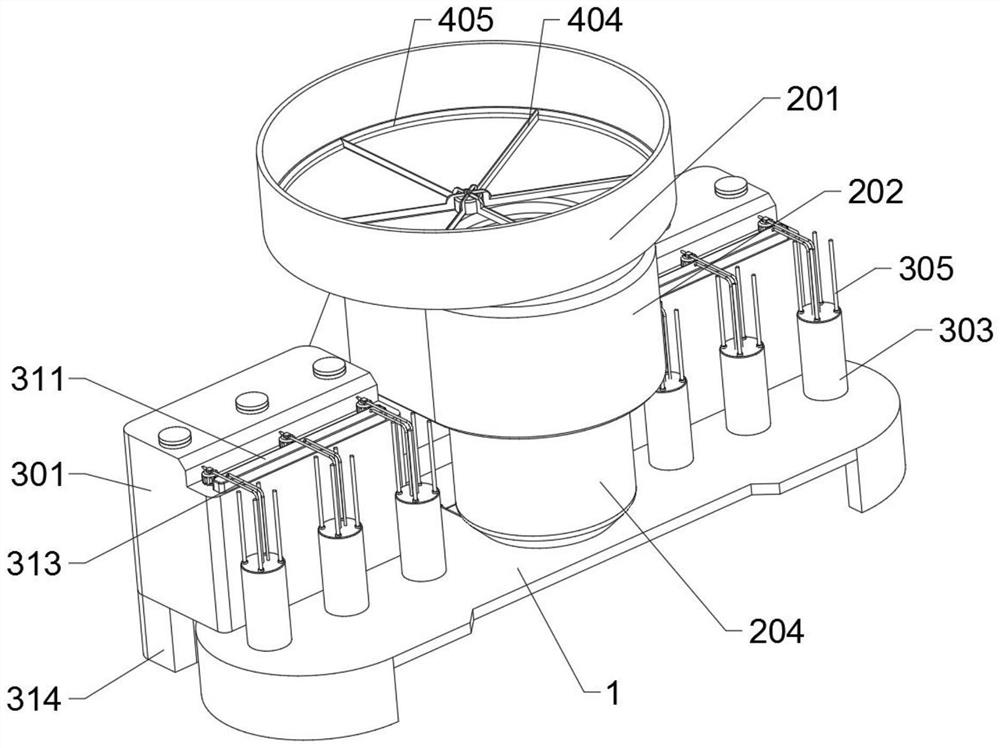

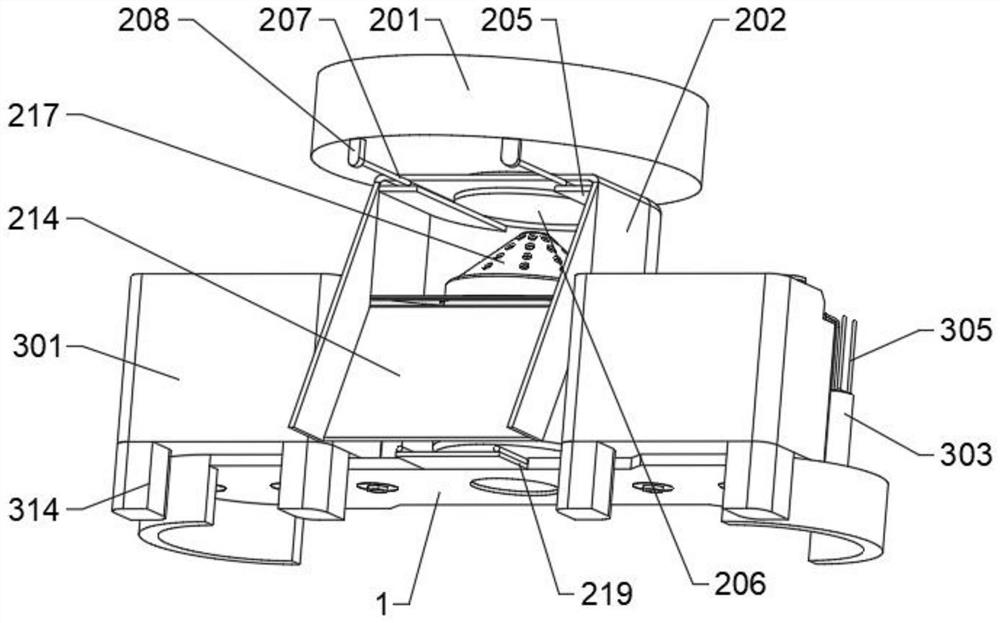

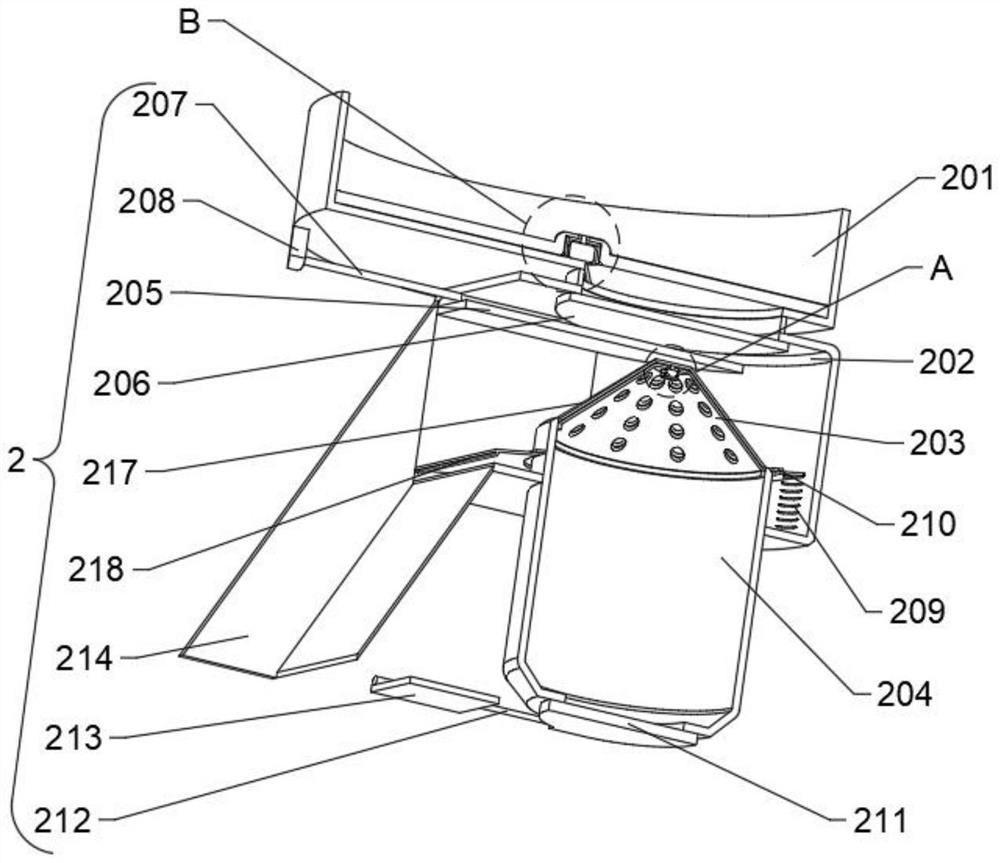

[0031] Example 1, such as Figure 1-8 As shown, the present invention provides a batching system for recycled concrete, comprising a base 1, a screening mechanism 2 is arranged on the base 1, a quantitative mechanism 3 is arranged on both sides of the screening mechanism 2, and a pushing mechanism 3 is arranged in the screening mechanism 2. Institution 4.

[0032] Let's talk about the specific settings and effects of its screening mechanism 2, quantitative mechanism 3 and pushing mechanism 4 below.

[0033] Such as Figure 1-3 with Figure 7-8 As shown, the screening mechanism 2 includes a material box 201, a fixed block 208 and a buffer spring 209. The material box 201 is used to store aggregates before screening, and the bottom of the material box 201 is connected with a screening box 202. To prevent the aggregate from being scattered when screening, the bottom of the screening box 202 is connected with a collection box 204, the top of the collection box 204 extends to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com