Lithium battery charging and discharging detection system and detection process

A detection system, lithium battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of battery classification, low efficiency, unsuitable for mass production and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

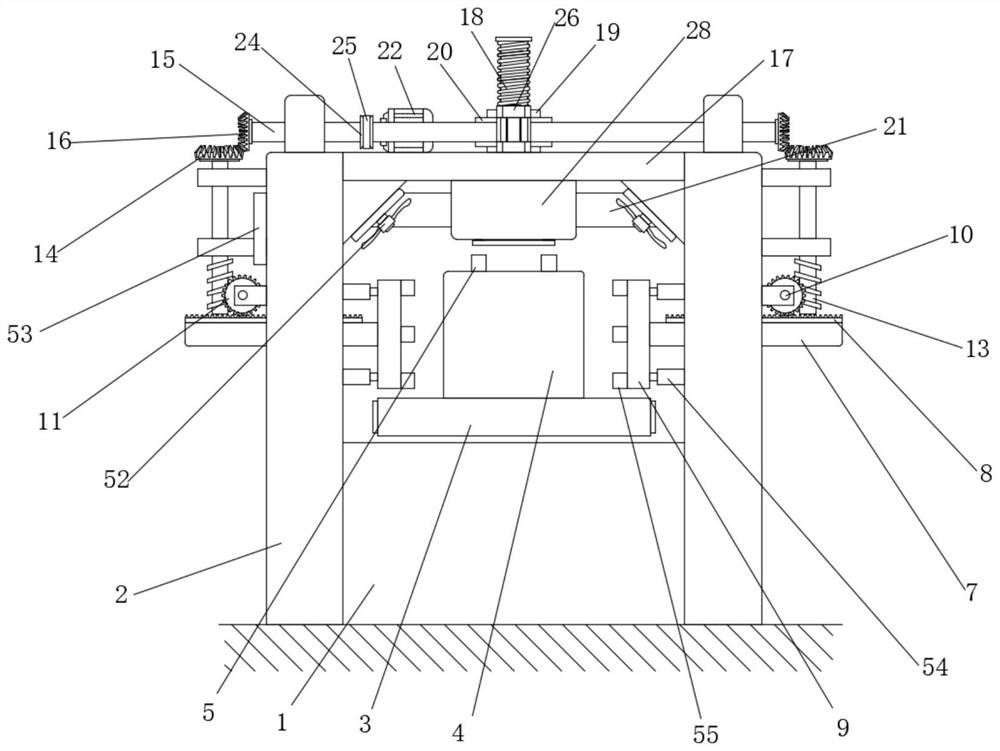

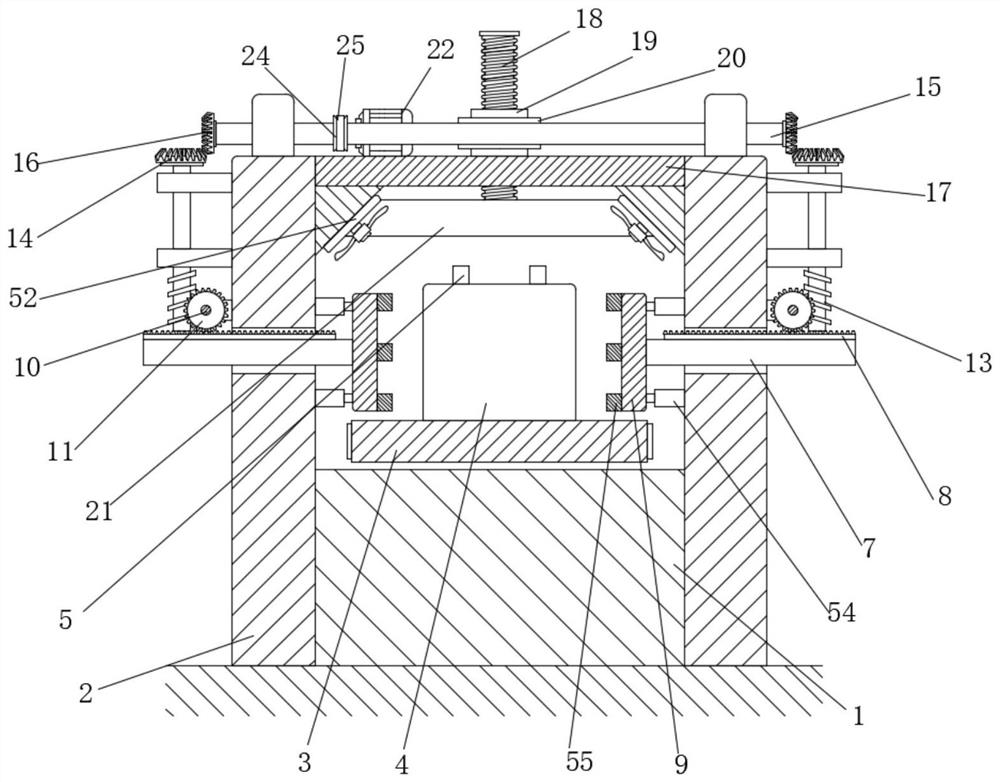

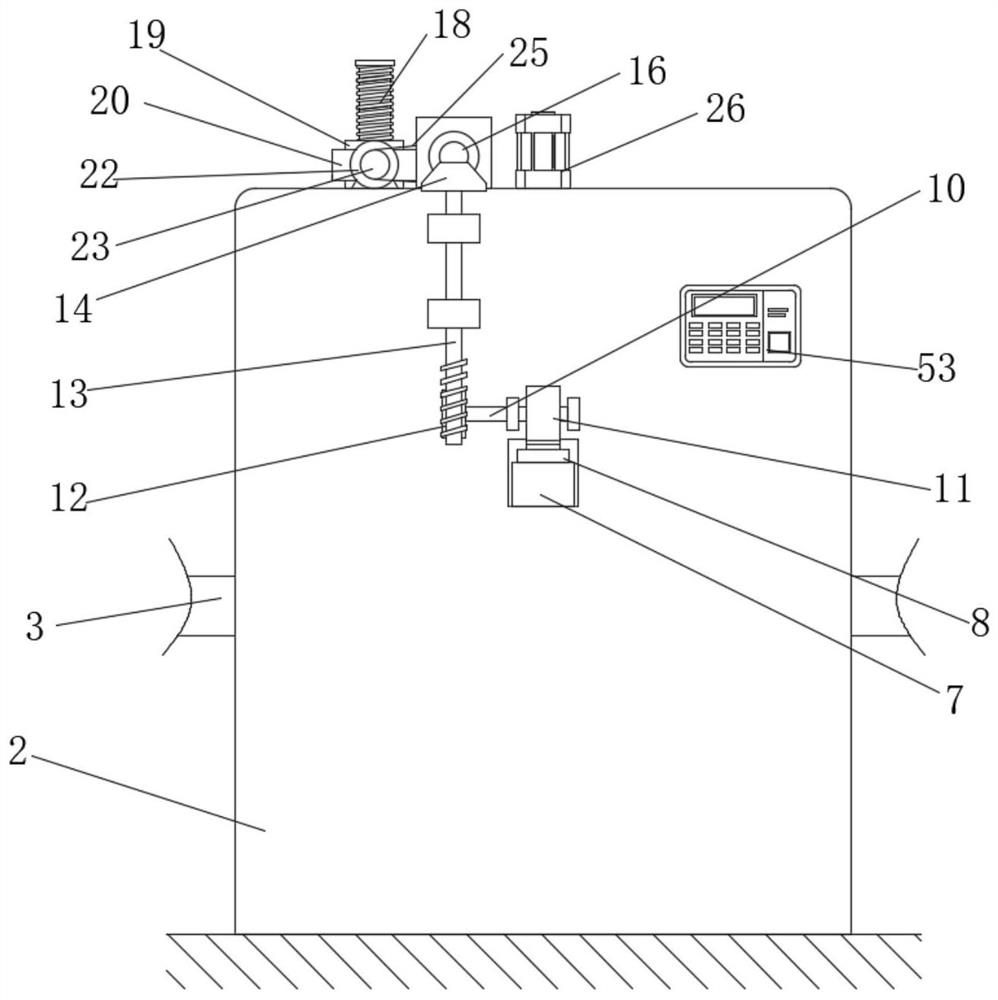

[0048] refer to Figure 1-12 , a lithium battery charge and discharge detection system, comprising a workbench 1, a conveyor belt 3 is arranged on the top of the workbench 1, a lithium battery 4 is placed on the top of the conveyor belt 3, and a positive and negative electrode connector 5 is fixedly connected to the top of the lithium battery 4 , both sides of the workbench 1 are fixedly connected with a support plate 2, and the side of the two support plates 2 close to each other is fixedly connected with the same placement plate 17, and the top of the placement plate 17 is provided with a fixed assembly for fixing the lithium battery 4, Two symmetrical fans 52 are fixedly connected to the bottom of the placement board 17 , and a testing assembly for testing the lithium battery 4 is provided on the top of the placement board 17 .

[0049] In the present invention, the fixed assembly includes a drive motor 22 fixedly connected to the top of the placement plate 17, the output s...

Embodiment 2

[0062] Embodiment two: if Figure 13 As shown in -16, a lithium battery charge and discharge detection system, the difference between this embodiment and Embodiment 1 is: the bottom of the detection box 28 is equidistantly arranged with a plurality of first extension springs 45, and a plurality of first extension springs 45 The bottom end of the connecting plate 46 is fixedly connected with the same connecting plate 46, and the connecting plate 46 is provided with a placement groove 47, and both sides of the connecting plate 46 are slidably connected with sliding rods 48, and the outer walls of the two sliding rods 48 are fixedly sleeved with a second Extension spring 49, one end of the two second extension springs 49 close to each other is fixedly connected with the connecting plate 46, and one end of the two second extension springs 49 away from the connecting plate 46 is fixedly connected with the outer wall of the sliding rod 48, and the two sliding rods 48 mutually approa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com