Shaft distance calibration method and system for robot chassis

A calibration method and robot technology, applied in instruments, measuring devices, etc., can solve the problem of low efficiency of the wheelbase of the robot chassis, and achieve the effect of solving the cumbersome manual wheelbase calibration, liberating labor productivity and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

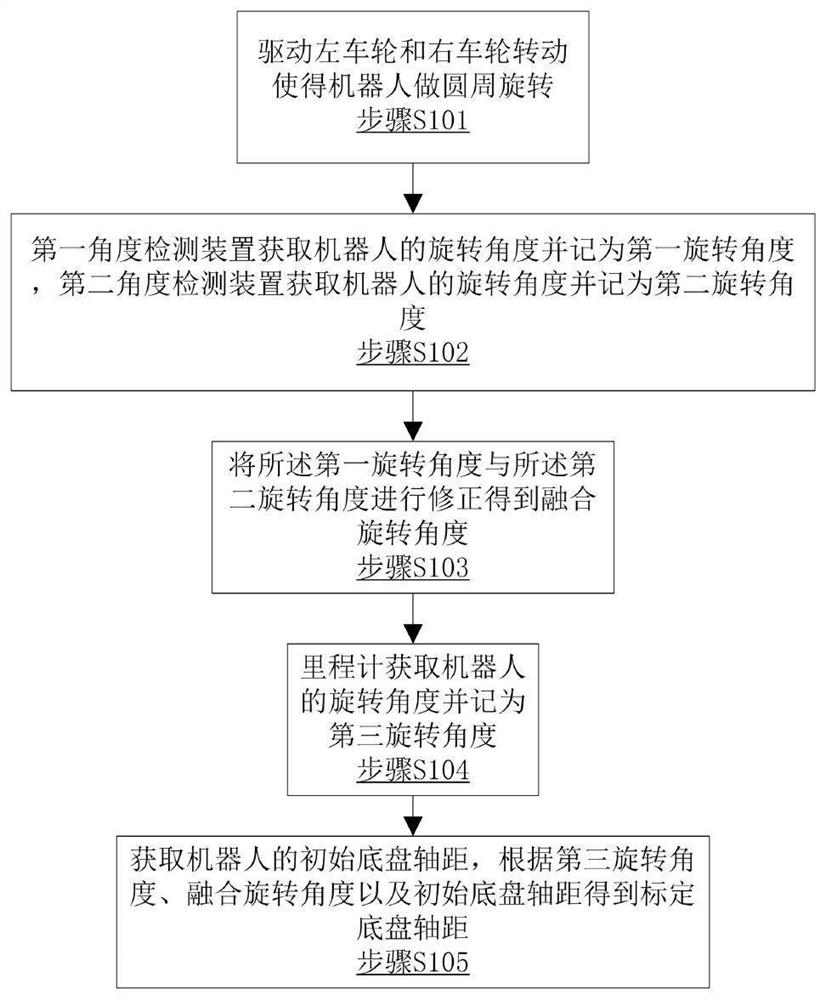

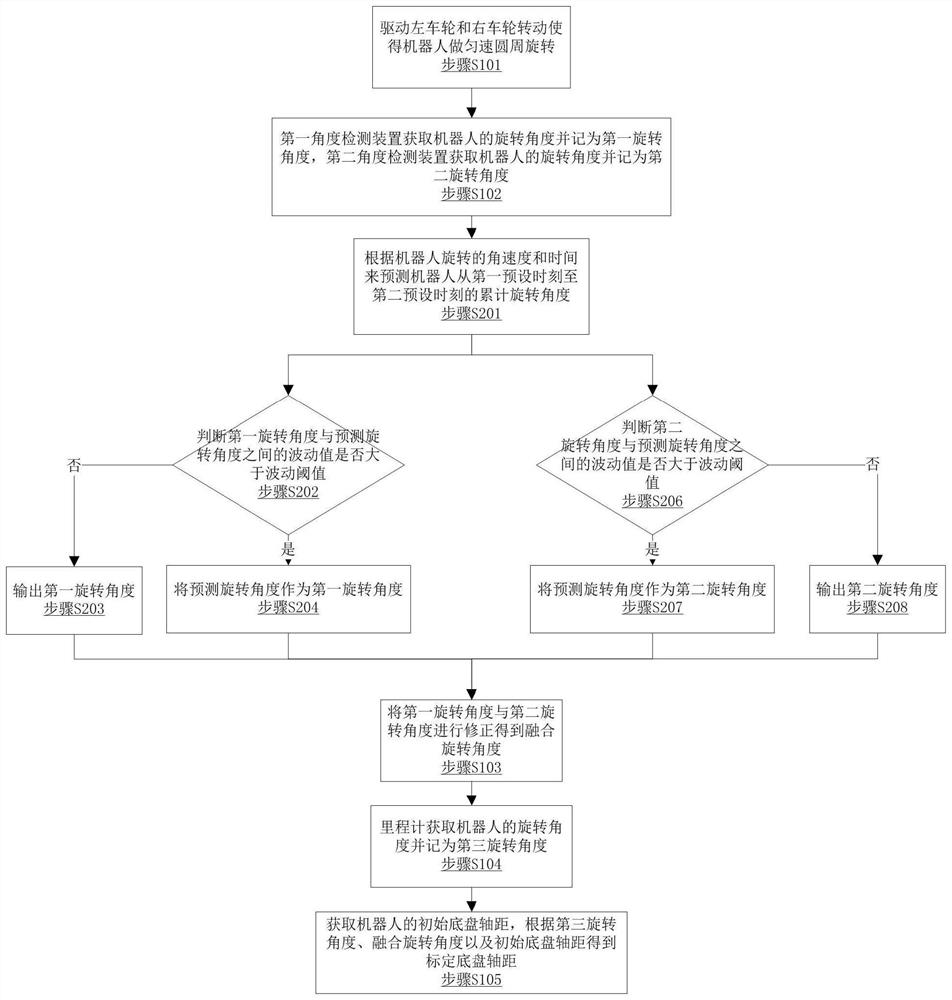

Method used

Image

Examples

Embodiment Construction

[0056] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

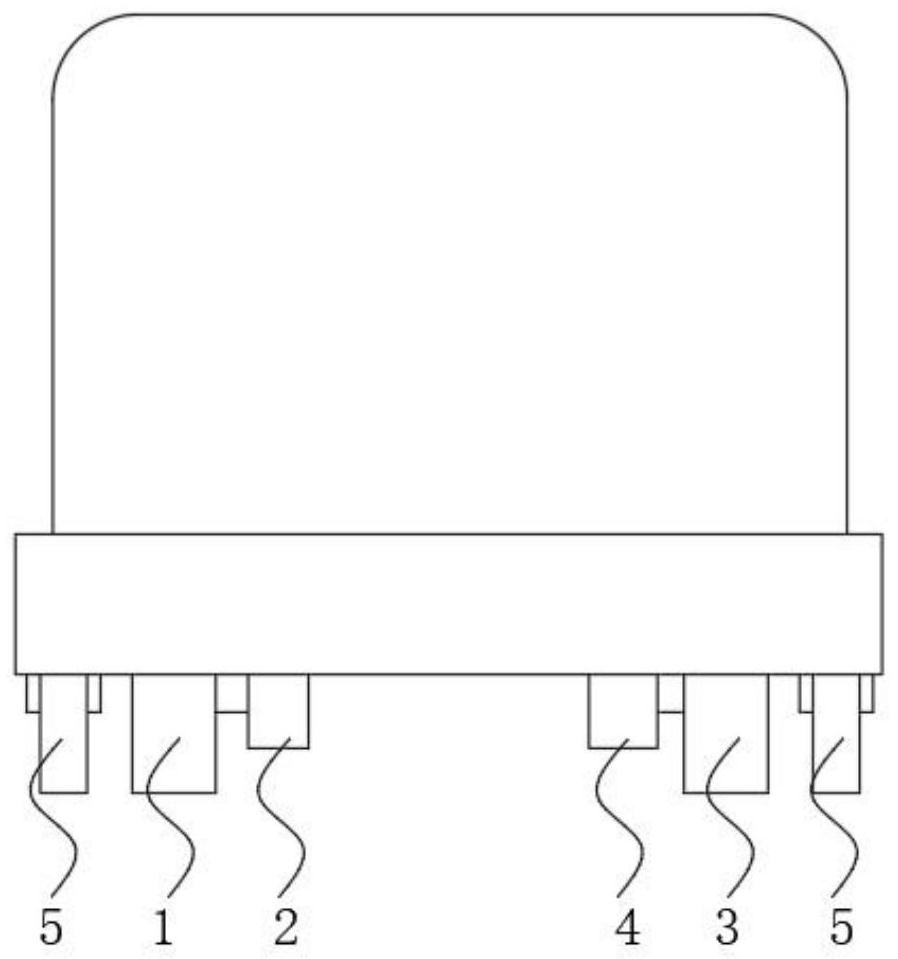

[0057] see image 3 , in this embodiment, the left wheel 1 of the robot is located on the left side of the robot chassis, and the right wheel 3 of the robot is located on the right side of the robot chassis, and the left wheel 1 and the right wheel 3 can drive the robot on the bearing surface toward Rotating left or right, the rotation axis of the robot is perpendicular to the carrying surface, which may be the ground. Left wheel 1 connects left wheel motor 2, and left wheel 1 rotates under the drive of left wheel motor 2, and right wheel 3 connects right wheel motor 4, and right wheel 3 rotates under the drive of right wheel motor 4. Also be provided with at least one auxiliary wheel 5 (can be universal wheel) on the robot chassis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com