Arc extinguishing chamber with multi-time arc extinguishing device

An arc-extinguishing device and arc-extinguishing hood technology are applied in the field of arc-extinguishing hoods, which can solve the problems of backflow of hot air into the contactor, poor arc-extinguishing effect, safety accidents, etc. Effects of Arc Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

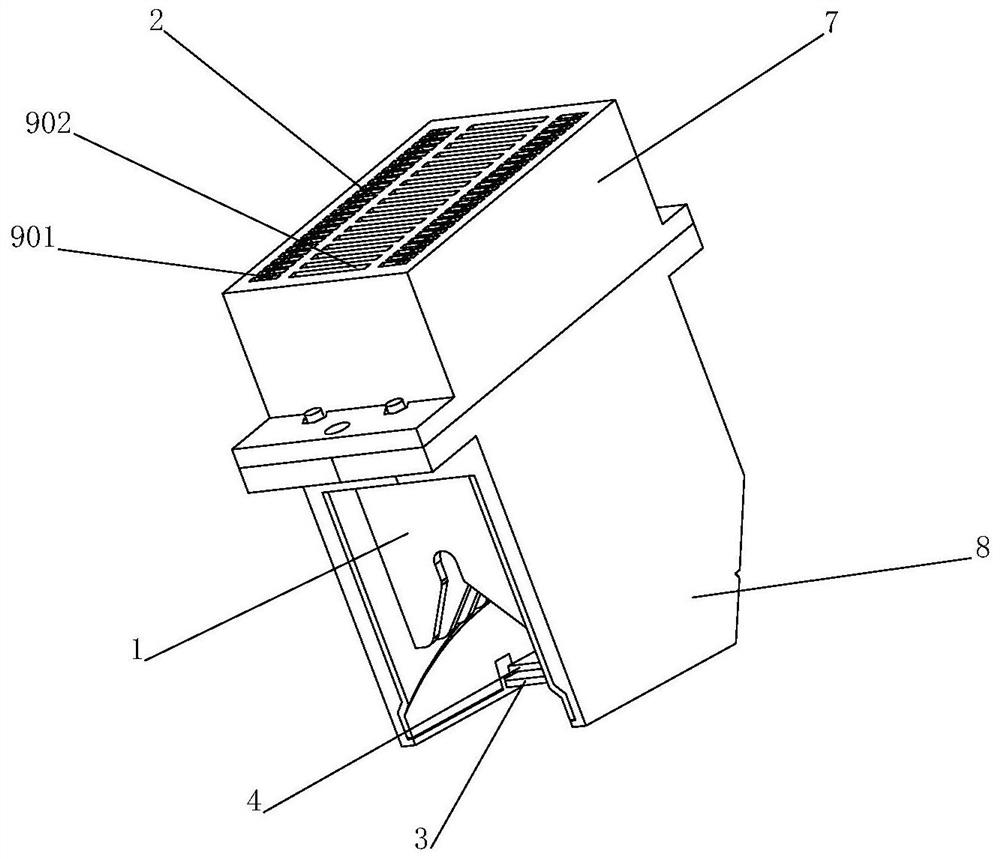

[0033] see Figure 1-8 , the present invention provides a technical solution: an arc extinguishing cover with multiple arc extinguishing devices in the present invention, including a housing, a primary arc extinguishing grid 1, a secondary arc extinguishing grid 2, an arc starting plate 3, and a gas generating plate 4. Zero flashover barbed wire 5 and insulating partition 6. The housing includes an upper housing 7 and a lower housing 8. Three rows of through-holes 9 are exposed at the upper end of the upper housing 7, and each row of twenty-five through-holes 9 serves as cooling holes for the arc extinguishing cover. Both sides of the upper end of the secondary arc extinguishing grid 2 protrude to form strips 201 and are installed in the through holes 9 on both sides, but do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com