Wire and cable wear resistance detection device

A technology of wear resistance and detection device, which is applied in the field of wire and cable, can solve the problems of wear resistance detection dependence, wear, and wire and cable are susceptible to friction, and achieve the effect of increasing friction and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

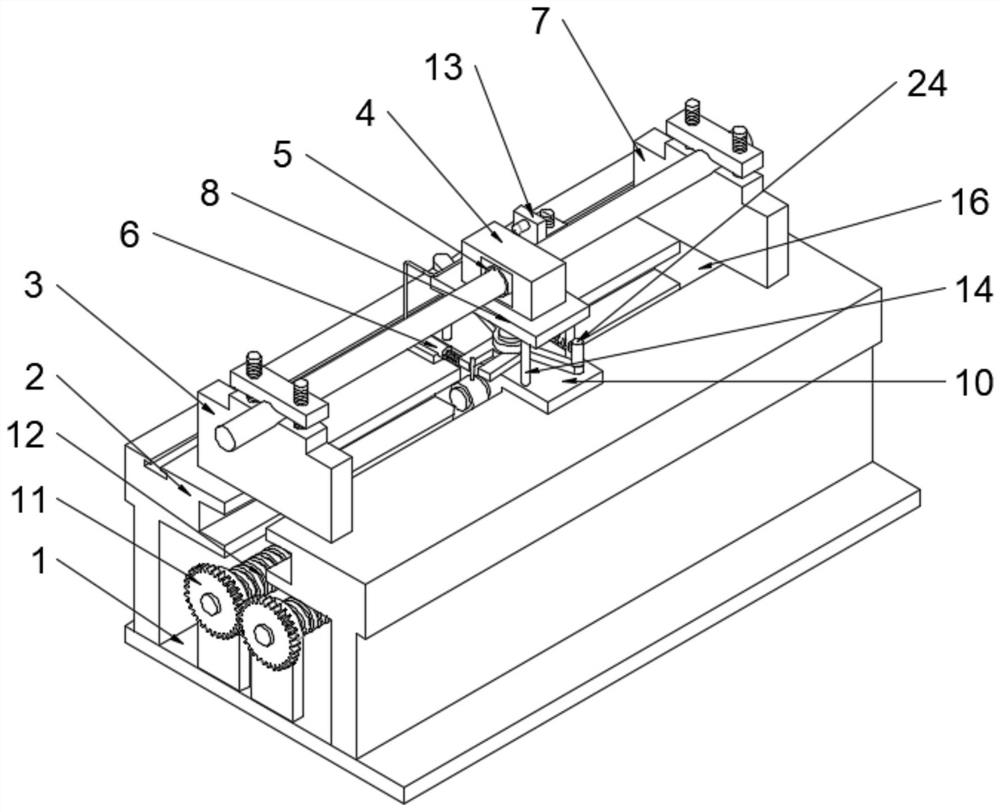

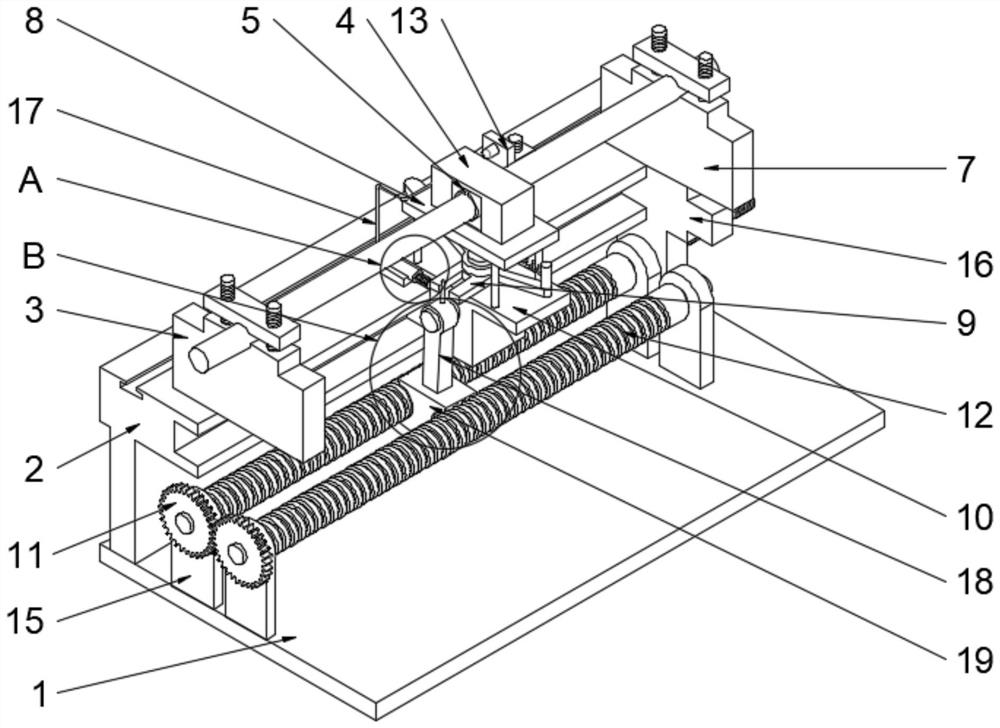

[0028] see Figure 1 to Figure 8 , the present invention provides a technical solution: a wear resistance detection device for wires and cables, two support frames 2 are symmetrically arranged on the upper surface of the mounting seat 1, and a limiting groove is opened on the opposite side of the support frame 2 and passes through the limit The groove is slidably connected with a sliding block 10, and the sliding block 10 is provided with a friction mechanism for repeatedly testing the wear resistance of the cable. The friction mechanism includes four support columns 14 fixed on the upper surface edge of the sliding block 10, four The upper surface of the support column 14 is fixedly connected with a support plate 8, and a detection block 4 is fixedly installed on the support plate 8. The surface of the detection block 4 is provided with a mounting groove, and the inner wall of the mounting groove is symmetrically provided with two contact pieces 5 that are in contact with the ...

Embodiment 2

[0040] Such as Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, it is basically the same as Embodiment 1. Furthermore, the surface of the sliding block 16 is provided with a threaded hole and is screwed with a screw 28 through the threaded hole, and the screw 2 28 runs through the sliding block. The threaded hole on the second 16 is fixedly connected with the connecting shaft of the screw rod one 12.

[0041] When the screw rod two 28 rotates, the sliding block two 16 can be opened in the limit groove on the opposite side of the support frame 2 to carry out limit sliding, and the thread on the sliding block two 16 is closer to that on the screw rod one 12. When rotating, the sliding block 2 16 can be moved in a small distance, and the clamp 2 7 can move slowly with a small distance along with the screw rod 2 28, so that the clamp 2 7 can slowly pull the cable to move, and the cable can be slowly pulled by the clamp 2 7 It can realize the detection of the wear ...

Embodiment 3

[0043] Such as figure 1 , Figure 4 and Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, it is basically the same as Embodiment 1 and Embodiment 2. Furthermore, a limiting groove is provided on one side of the edge of the support frame 2 and the sliding is limited through the limiting groove. Two limit blocks 13 are connected, and the opposite sides of the two limit blocks 13 are fixedly connected with touch posts. The upper surface of the limit block 13 is provided with a threaded hole, and a knob for fixing it is screwed through the threaded hole. .

[0044] By setting the limit block 13, when the movable rod 29 is in contact with the touch column on the limit block 13, under the driving force of the limit block 13, the column two 27 fixedly connected with the movable rod 29 will move on the sliding block one. The upper surface of 10 is rotated, and it is unscrewed by turning the knob, so that the stop block 13 can be slid in the stop groove on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com