Preparation method and repairing method for repairable dynamic infrared radiation regulation and control material

A technology of infrared radiation and repair method, applied in the field of preparation of infrared radiation regulation materials, can solve the problems of complex excitation mode and poor stability, and achieve the effect of effective infrared radiation regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation mode 1: In this implementation mode, a method for preparing a repairable dynamic infrared radiation control material is completed according to the following steps:

[0027] 1. Preparation of SEBS solution:

[0028] Adding SEBS powder into THF, completely dissolving the SEBS powder into THF under the conditions of magnetic stirring and heating to obtain SEBS solution;

[0029] 2. Scratch coating of SEBS film:

[0030] Pour the SEBS solution on a clean glass surface, and then use a manual scraper to scrape and coat it to form a film;

[0031] 3. Peel off the SEBS film:

[0032] Dry the SEBS film scraped on the glass at room temperature, soak it in an ethanol solution after drying, and peel the SEBS film from the glass in the ethanol solution, transfer the SEBS film to the surface of the filter paper, and then dry it in an oven. Obtain an unsupported SEBS film;

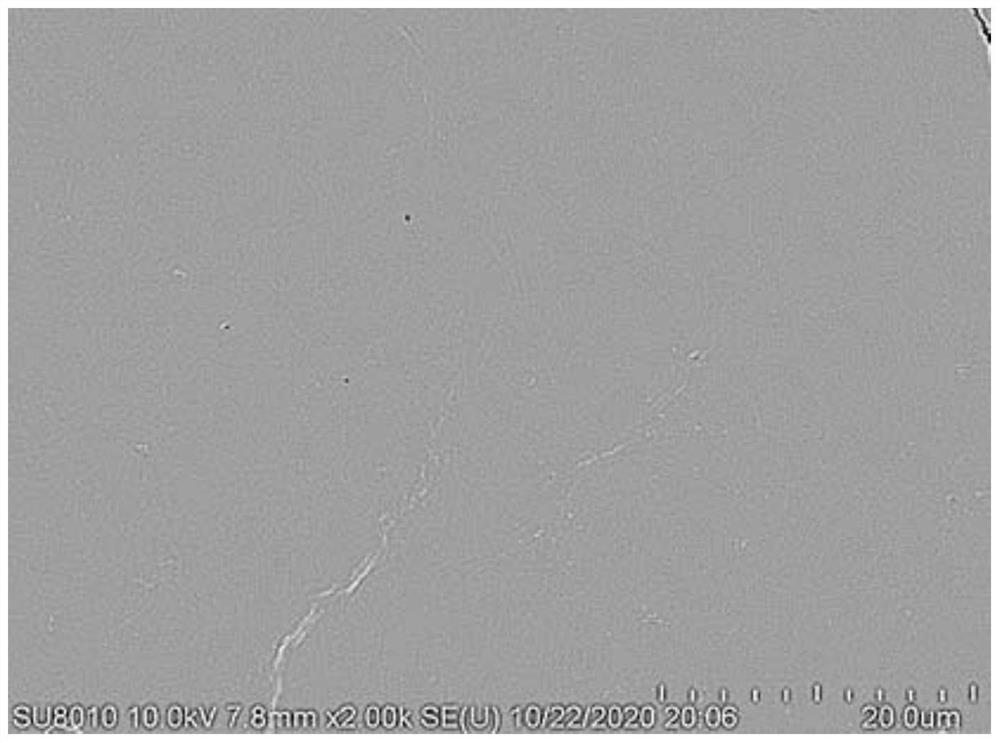

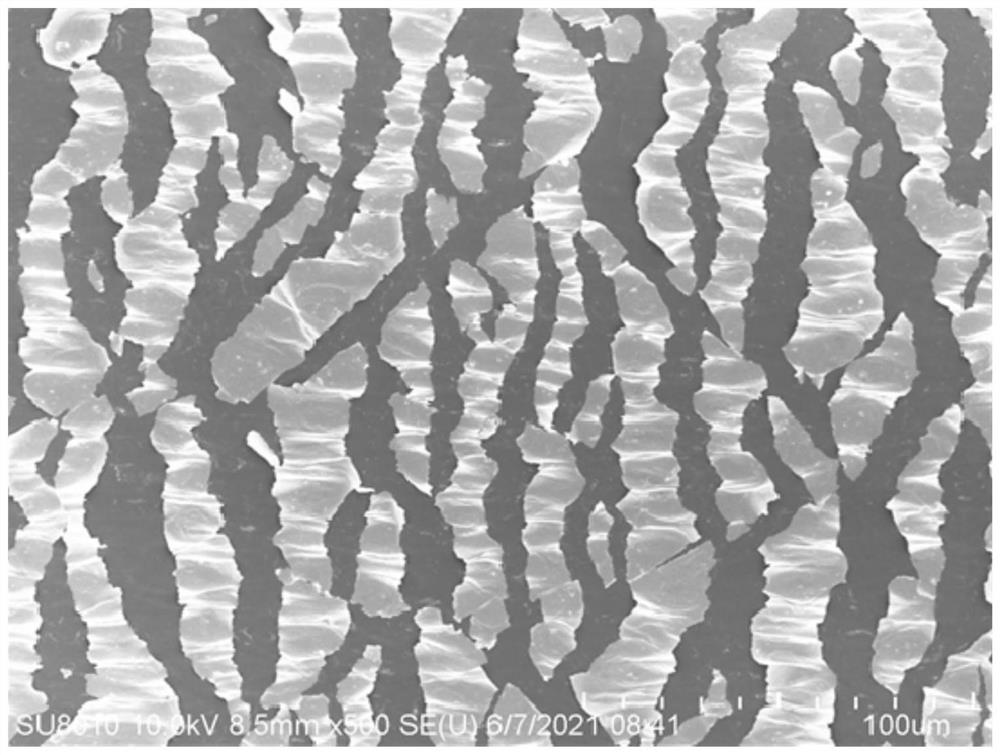

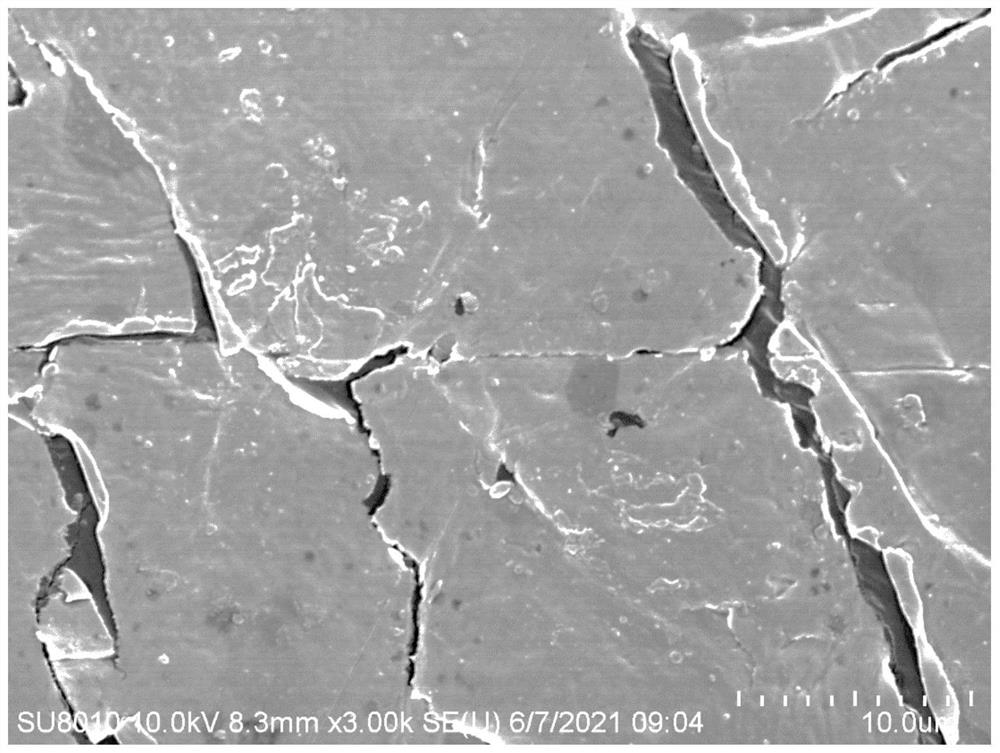

[0033] 4. Preparation of gold-plated SEBS film:

[0034] The vacuum thermal evapor...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of the SEBS solution described in step 1 is 6% to 12%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the speed of the magnetic stirring described in step 1 is 100r / min-1000r / min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap