Stepless speed regulation reciprocating piston compressor suitable for new energy automobile

A new energy vehicle, stepless speed regulation technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

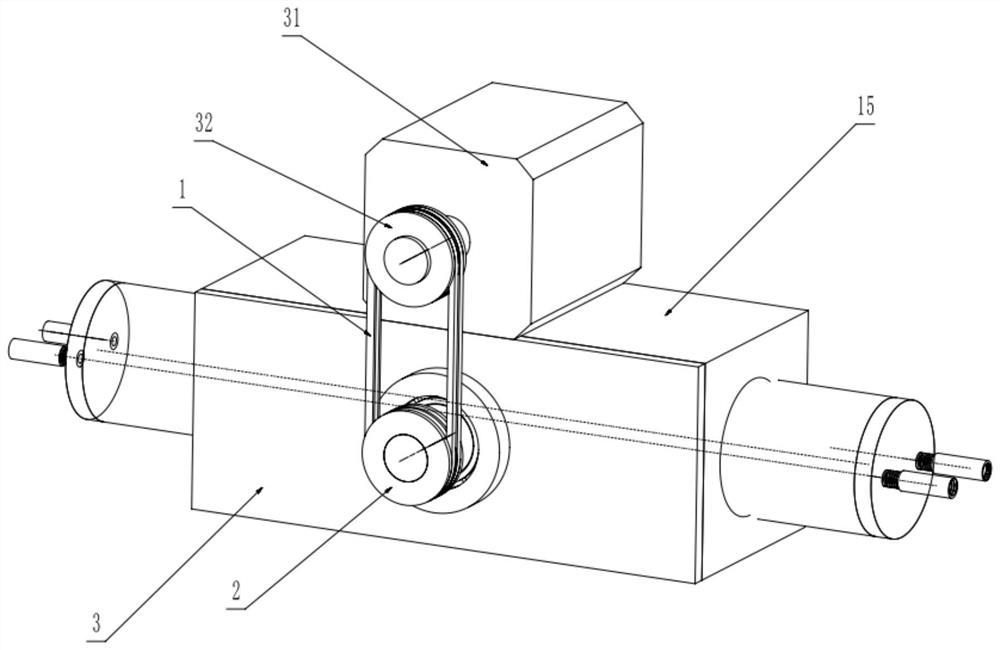

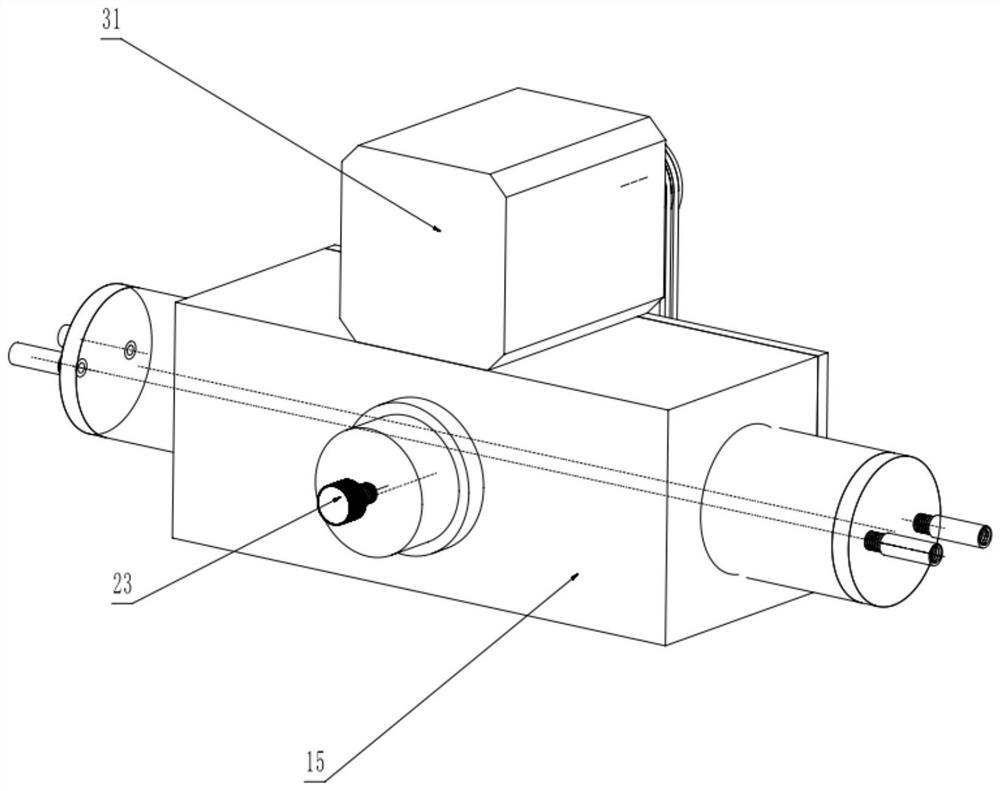

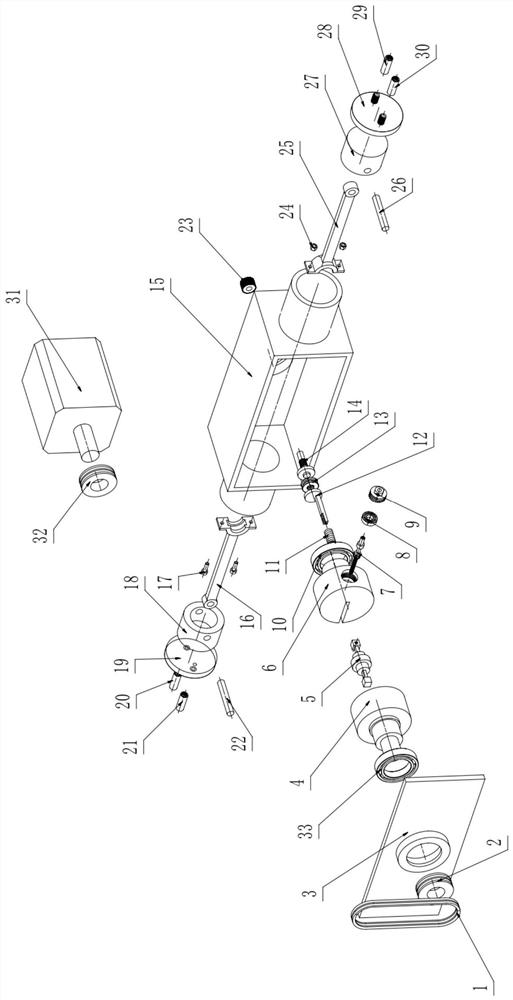

[0042] like Figure 1-6 As shown, this embodiment provides a steplessly speed-adjustable reciprocating piston compressor suitable for new energy vehicles, including a cylinder block, a drive shaft 4, a driven shaft 6, a compression mechanism and a speed regulating mechanism; the drive shaft 4 and the driven shaft The moving shaft 6 is coaxially installed on both sides of the cylinder body; the compression mechanism includes a crankshaft 5, a first connecting rod 16 and a second connecting rod 25, and the two ends of the crankshaft 5 are respectively installed in the drive shaft 4 and the driven shaft 6, and the second One end of a connecting rod 16 is installed on the crankshaft 5 surface, and the other end is connected with the first piston 18 by the first pin 22, and one end of the second connecting rod 25 is installed on the crankshaft 5 surface, and the other end is connected with the second pin 26 The piston 27, the first piston 18 and the second piston 27 are respectivel...

Embodiment 2

[0051] like Figure 5 and 7 As shown, the present embodiment provides a steplessly speed-adjustable reciprocating piston compressor suitable for new energy vehicles. The crankshaft body 501 of the crankshaft 5 is provided with a convex ring 502, and the first connecting rod 16 and the second connecting rod 25 The ends are provided with grooves matching the protruding ring 502 , and the first connecting rod 16 and the second connecting rod 25 are connected by matching first screws 17 and first nuts 24 and installed on the surface of the crankshaft 5 . The structure of the groove and the protruding ring 502 can limit the axial movement of the crankshaft 5 .

[0052] like figure 1 and 2 As shown, a drive motor 31 is provided above the cylinder block, a first pulley 32 is installed on the output shaft of the drive motor 31, and a second pulley 2 is installed on the end where the drive shaft 4 stretches out of the cylinder block, and the first pulley 32 and the second pulley are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com