Multichannel pipetting head

A multi-channel, pipetting head technology, applied in the direction of measuring tubes/pipettes, laboratory utensils, laboratory containers, etc., can solve problems affecting the accuracy and accuracy of pipetting, and achieve compensation for manufacturing tolerances, The effect of a small dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

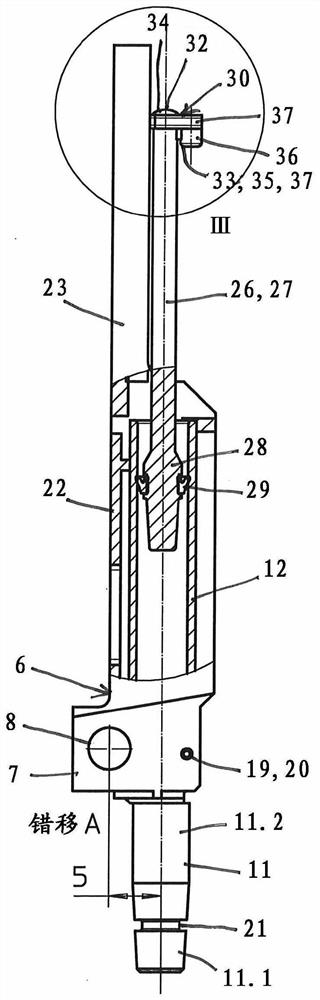

[0037] In the present application, the terms "upper" and "lower" and "sideways" relate to multichannel pipetting heads which are vertically oriented in a piston-cylinder unit and in which the drive rod is arranged above the pin.

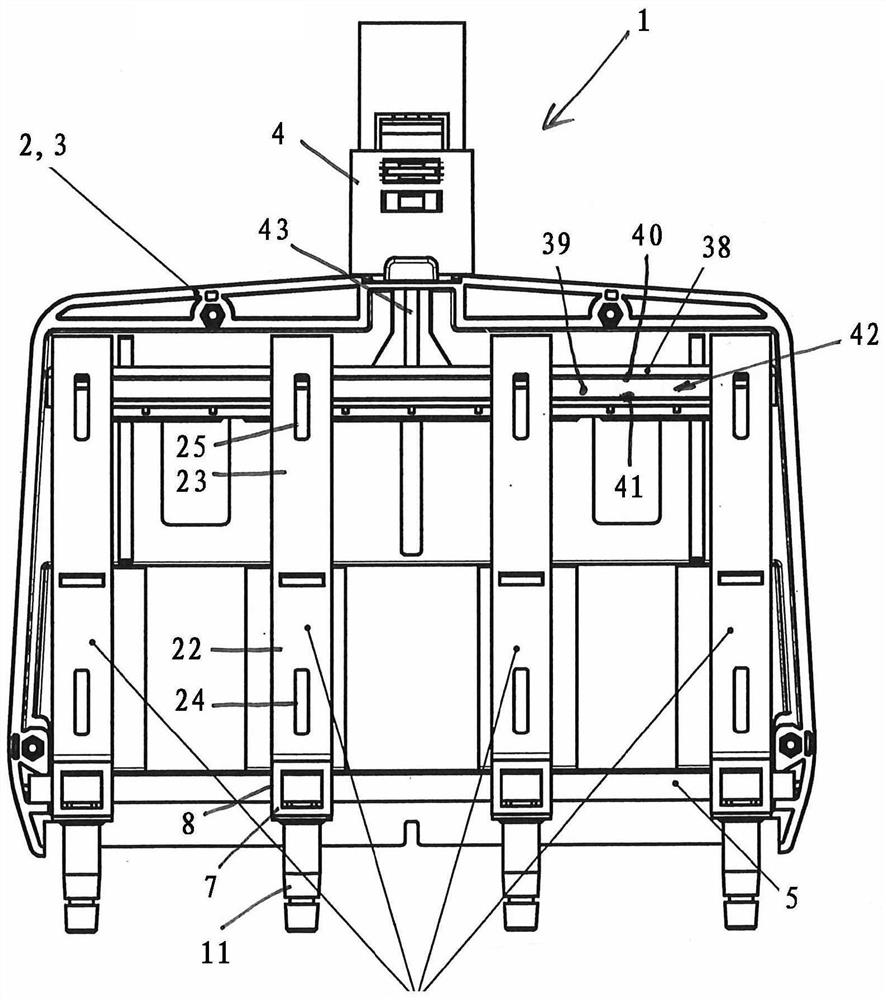

[0038] according to Figures 1 to 3 , the multichannel pipetting head 1 has a support structure 2 which is formed by a two-part housing 3 . exist figure 1 In , the front housing part is removed so that only the rear housing part is shown. Alternatively, the support structure can also be formed by a chassis, which is covered with a housing.

[0039] The casing 3 is basically box-shaped. On the upper edge of the housing 3 , a fastening pin 4 protrudes vertically upwards, said fastening pin being used for connection to the upper part of the pipette.

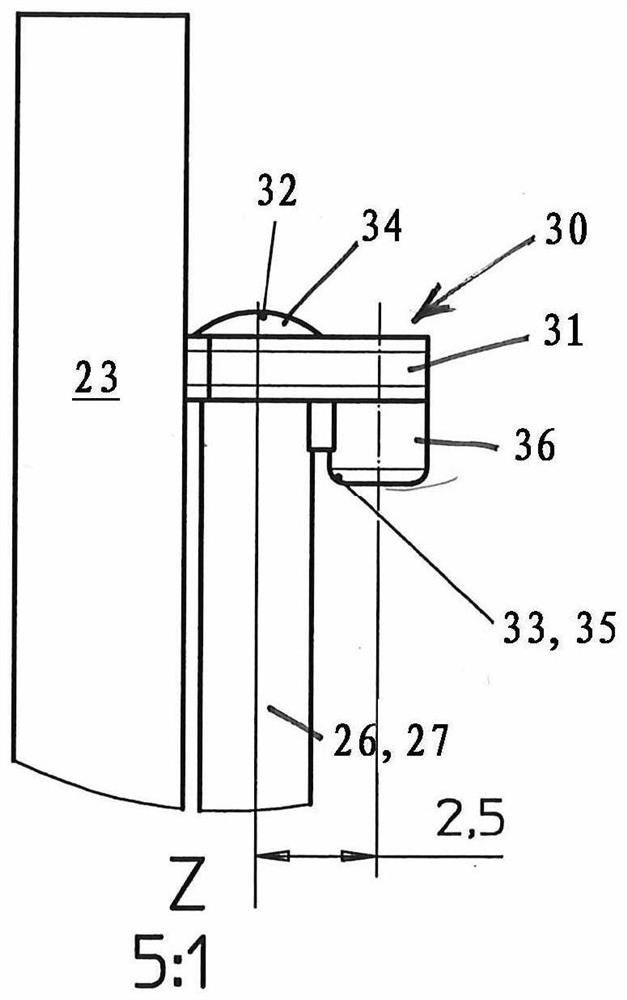

[0040] A horizontal shaft 5 with a circular cross section is held in the housing. On the shaft 5 a plurality of guides 6 (in the example 4) are displaceable in the horizontal direction and are mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com