Bending machine convenient for supporting materials and checking

A bending machine and material support technology, applied in the field of bending machines, can solve the problems of lack of calibration structure, lack of pressure control structure, lack of support structure, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

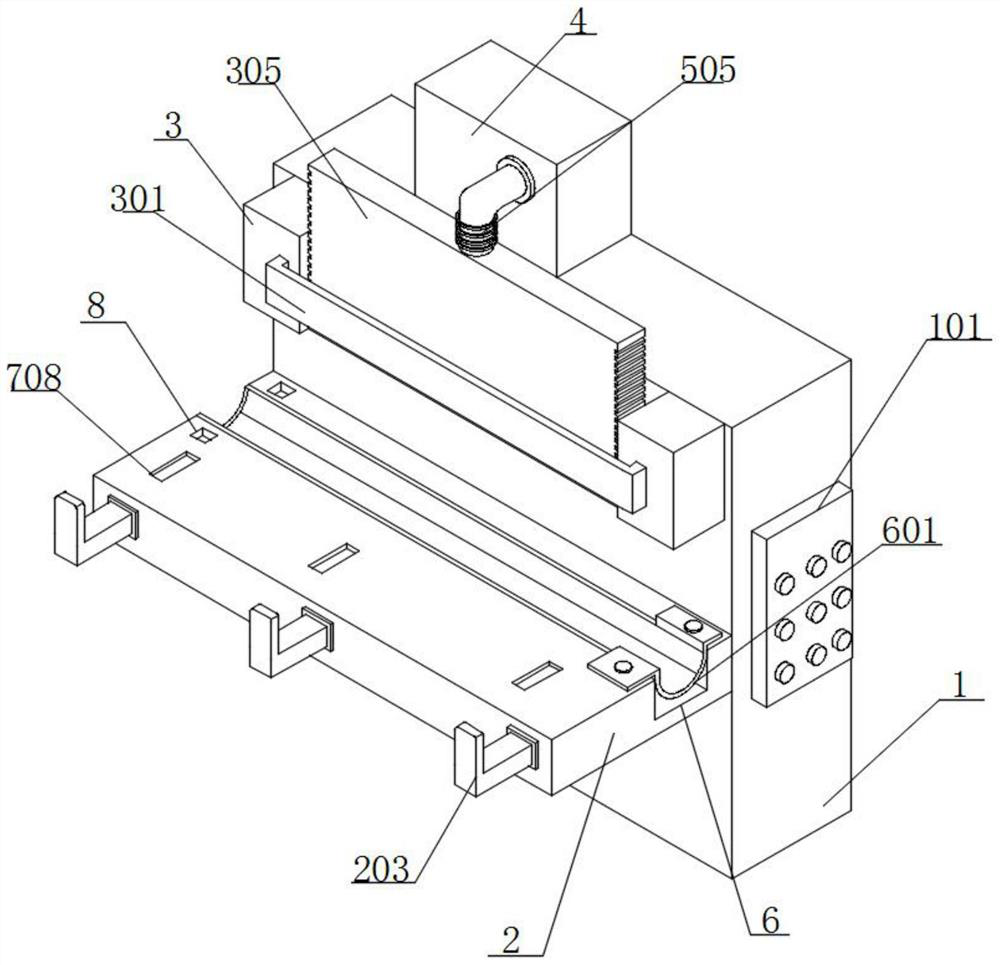

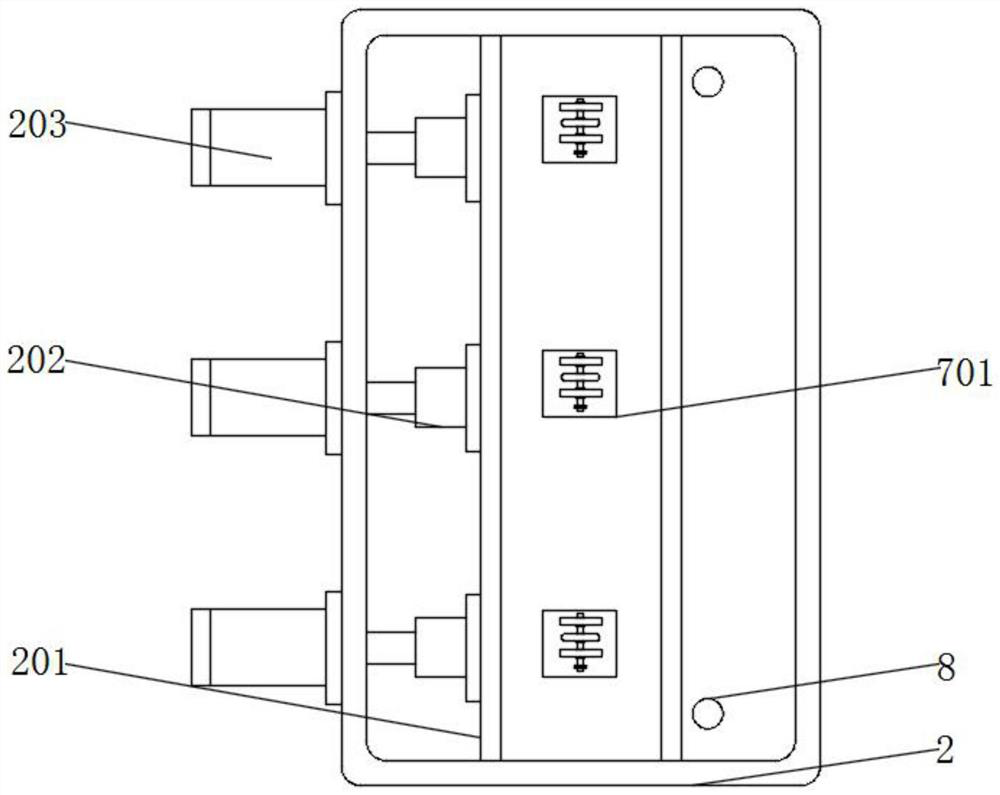

[0043] Example 2: see figure 1 and figure 2 , an embodiment provided by the present invention: a bending machine that is convenient for checking materials, two groups of partition plates 201 are installed on the inner bottom wall of the support plate 2, and a first electric telescopic rod is installed on the front of the partition plate 201 202, and one end of the first electric telescopic rod 202 extends out of the front of the support plate 2, and one end of the first electric telescopic rod 202 is equipped with an L-shaped auxiliary plate 203, when it is necessary to check the bending situation of the plate, the second The motor 706 reverses, and three groups of rubber wheels 705 drive the plate to move on the support plate 2. The extension of the first electric telescopic rod 202 drives the extension of the auxiliary plate 203, and then the plate falls on the auxiliary plate 203, which is convenient for the staff to observe.

Embodiment 3

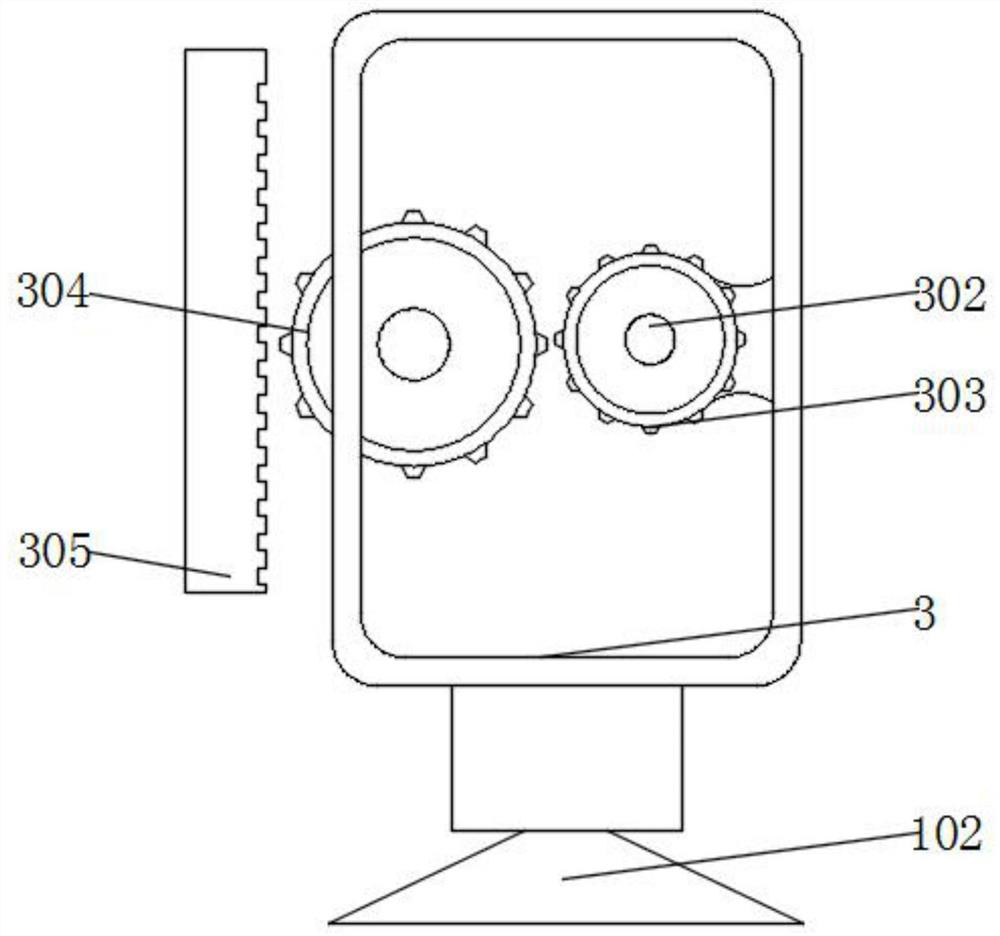

[0044] Example 3: See image 3 , Figure 4 and Figure 5 , a kind of embodiment that the present invention provides: a kind of bending machine that is convenient to hold material to check, and the front of lifting box 3 is installed with protective plate 301, and the inner wall of lifting box 3 is installed with first motor 302, and the output of first motor 302 No. 1 gear 303 is installed at the end, No. 2 gear 304 is installed on the inner rear wall of lift box 3, and No. 2 gear 304 is meshed with No. 1 gear 303, and the outer wall of No. 2 gear 304 extends out of the outer wall of lift box 3. The outer wall of the gear 304 is equipped with a bending plate 305 through gear meshing, the inner bottom wall of the adjustment box 4 is equipped with a storage box 401, the inside of the storage box 401 is filled with high-density liquid, and the top of the storage box 401 is installed with a first water pump 402, The input end of the first water pump 402 is equipped with a water ...

Embodiment 4

[0045] Example 4: See Figure 6 , Figure 7 and Figure 9 , an embodiment provided by the present invention: a bending machine that is convenient for checking the supporting material, the top of the bending groove 6 is equipped with an arc bender 601, and the top of the arc bender 601 is installed with a limit plate 602, The bottom of the arc bender 601 is equipped with a fixed column 603, the inner bottom wall of the fixed column 603 is equipped with a mounting rod 604, and the top of the mounting rod 604 extends out of the top of the limit plate 602, and the outer wall of the mounting rod 604 is installed with multiple A cam 605, the inner wall of the fixed post 603 is penetrated with a plunger, the outer wall of the plunger is surrounded by a return spring 607, one end of the plunger is equipped with a strike plate 606, and the outer wall of the mounting rod 604 is fitted with a limit gear 608, and the limit The gear 608 is located inside the limit disc 602. Two sets of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com