Rigid-flexible wall supporting mechanism for elevator shaft

An elevator shaft, rigid and flexible technology, applied in elevators, transportation and packaging, etc., can solve the problems of lack of calibration structure, low installation accuracy of elevator intelligent installation system, etc., to improve installation efficiency, good self-stability, avoid rotation and tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

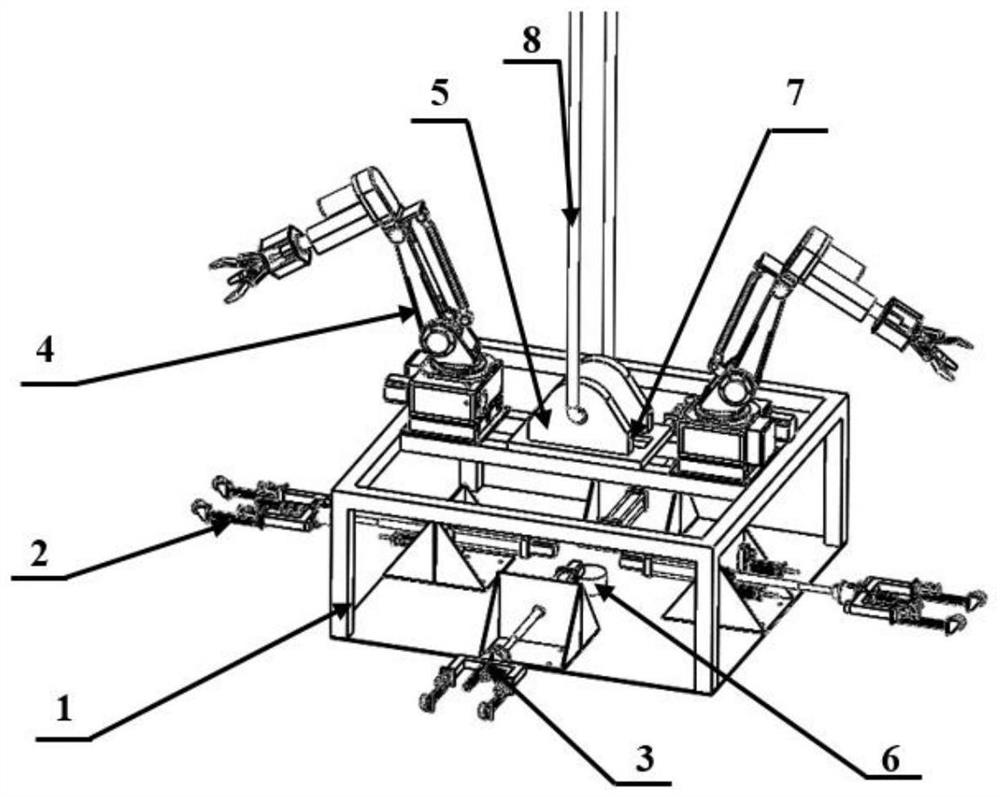

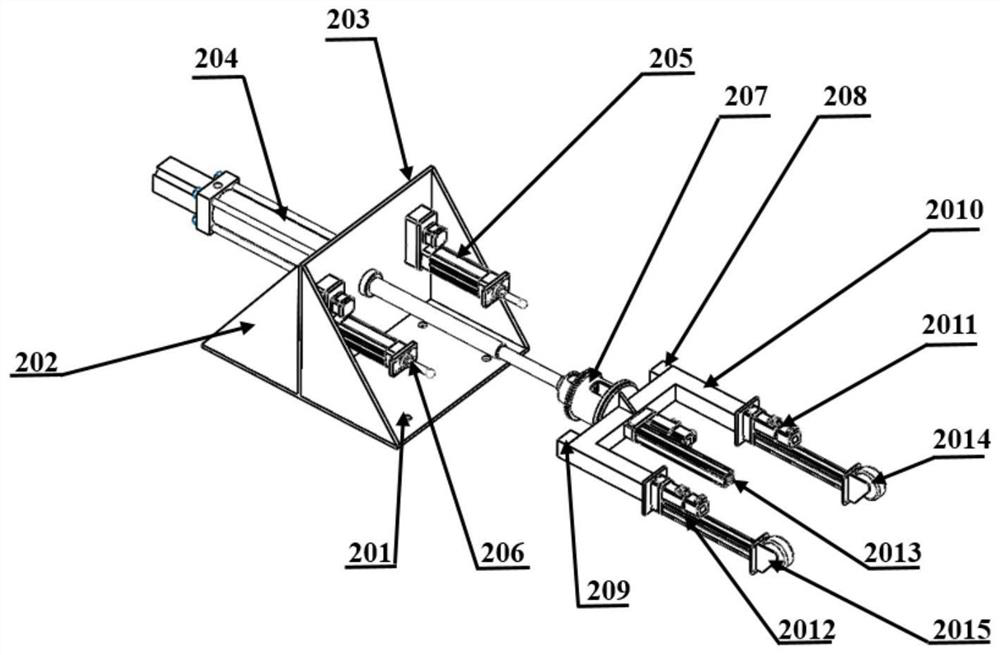

[0037] The present invention provides a rigid and flexible elevator shaft supporting wall mechanism, refer to figure 1 , the wall supporting mechanism mainly includes: a frame 1, a wall supporting mechanical arm 2, an adjusting mechanical arm 3, a guide rail installation and adjusting manipulator 4, a traction support 5, a vertical pose detection part 6, a horizontal pose detection part 7 and Wire rope 8. Concretely, the described a kind of elevator hoistway is rigid and flexible and supports the wall mechanism, comprises frame 1, is used for fixing and installing each component in the wall support mechanism; Wall support mechanical arm 2, is used for adjusting the level of the wall support mechanism , the vertical posture state, and the contact with the surface of the elevator shaft wall to provide wall support; the adjustment mechanical arm 3 is used to adjust the horizontal and vertical posture states of the wall support mechanism, contact with the elevator shaft wall surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com