High-speed motor with lubricating function

A high-speed motor and functional technology, applied in lubricating oil containers, lubricating parts, engine lubrication, etc., can solve the problems of single function and small application range, and achieve the effect of easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

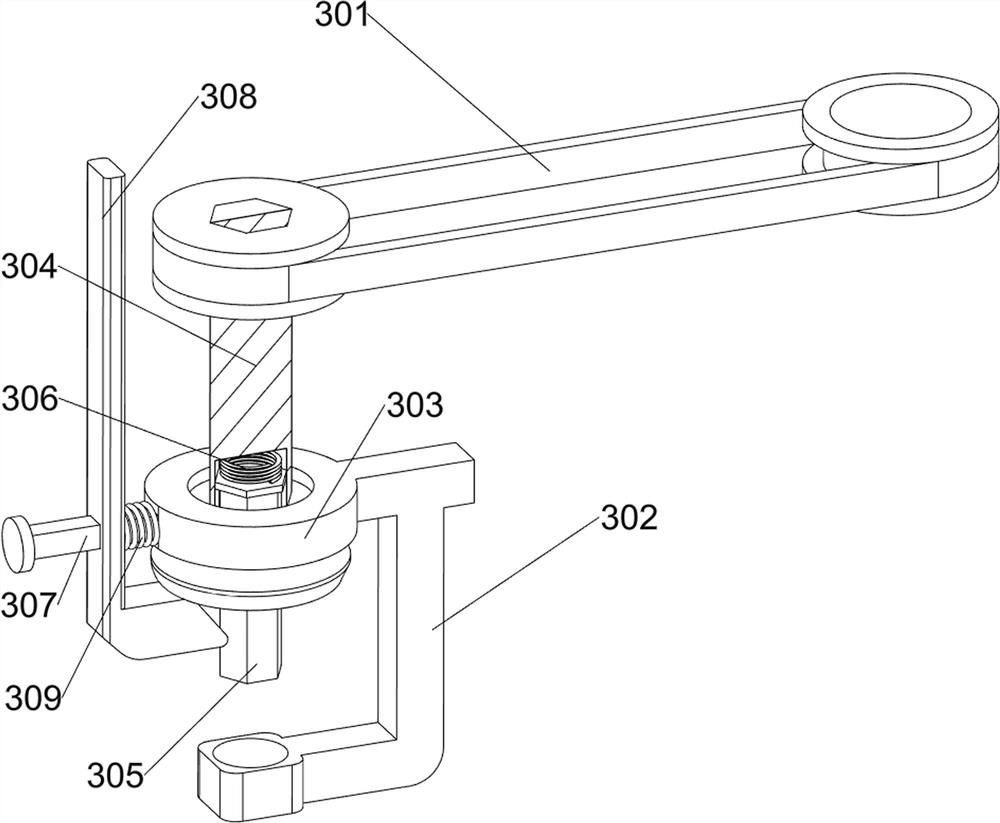

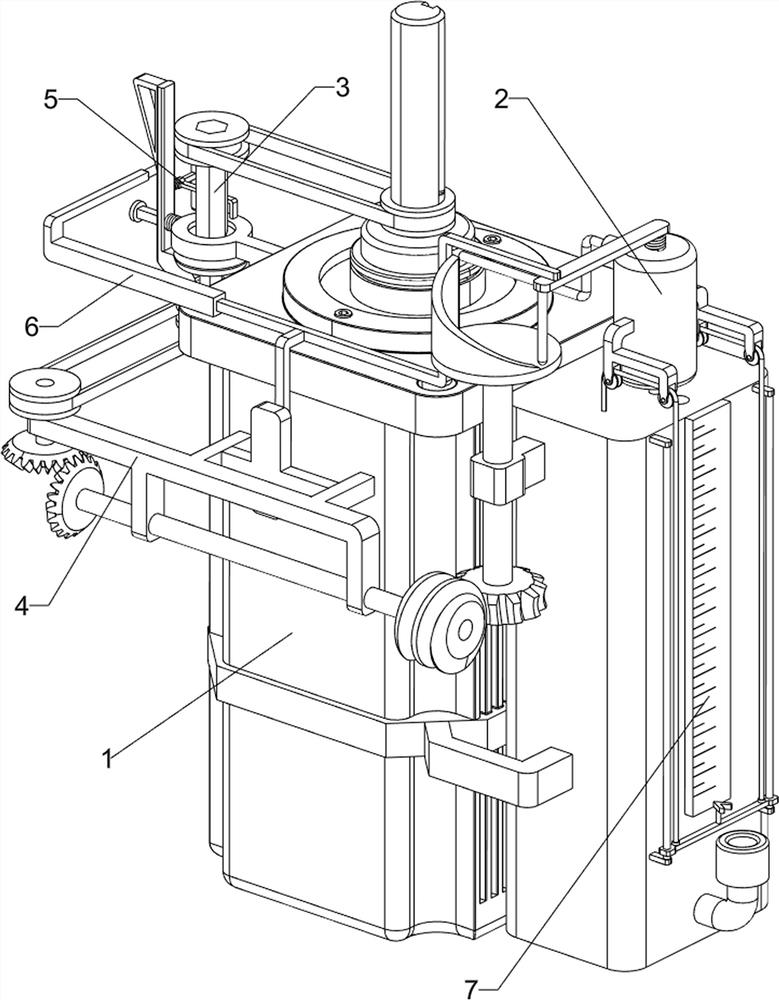

[0079] A high-speed motor with lubrication function, such as figure 1 and figure 2 As shown, it includes a high-speed motor 1, a lubricating component 2, a disengagement component 3 and a driving component 4, a lubricating component 2 is connected between the inner side of the high-speed motor 1, a disengagement component 3 is connected to the output shaft of the high-speed motor 1, and the front of the high-speed motor 1 The drive assembly 4 is connected to the side.

[0080] When the device needs to be used, the user can pour lubricating oil into the lubricating component 2 to achieve the purpose of lubricating the high-speed motor 1. The initial state of the detached component 3 is in a compressed state. Loosen the detached component 3 and detach Component 3 slides down to start the high-speed motor 1. The high-speed motor 1 reverses to drive the detachment component 3 to reverse, and the detachment component 3 reverses to drive the drive component 4 to reverse. When the ...

Embodiment 2

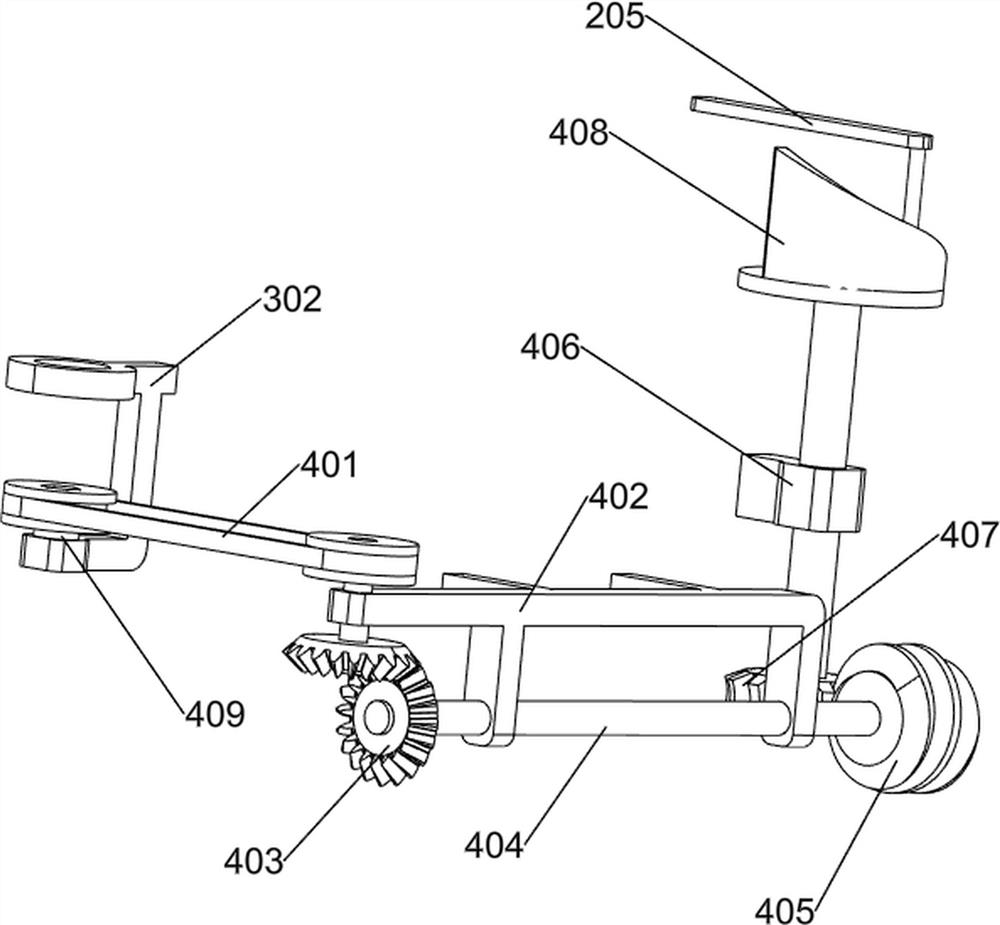

[0082] On the basis of Example 1, such as image 3 As shown, the lubrication assembly 2 includes a storage cylinder 201, a one-way material inlet 202, a piston cylinder 203, a first piston 204, a first push rod 205, a first spring 206, a feed pipe 207, a discharge pipe 208 and Material retaining cover 209, high-speed motor 1 is connected with material storage cylinder 201, and the right side of material storage cylinder 201 is connected with one-way material inlet 202, and the inside of material storage cylinder 201 is connected with feed pipe 207, and feed pipe 207 passes through storage Material cylinder 201, the upper side of feed pipe 207 is connected with piston cylinder 203, and the first piston 204 is slidably connected in the piston cylinder 203, and the first push rod 205 is connected with the first piston 204 upper side, and the first piston 204 and piston cylinder 203 is provided with a first spring 206, the first spring 206 is located on the upper side of the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com