Efficient roadbed flattening device for highway engineering construction

A technology of engineering and roadbed, applied in the field of high-efficiency roadbed flattening device, can solve the problems of cumbersome operation, inconvenient carrying, and affecting the construction efficiency of road engineering, and achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

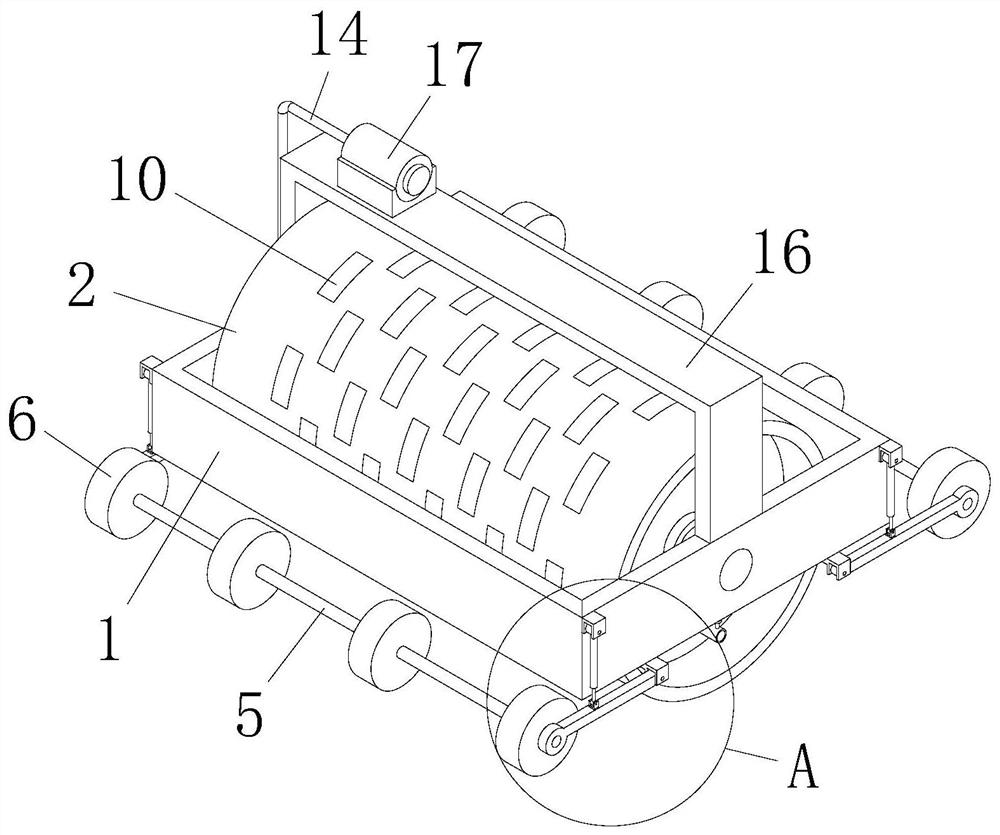

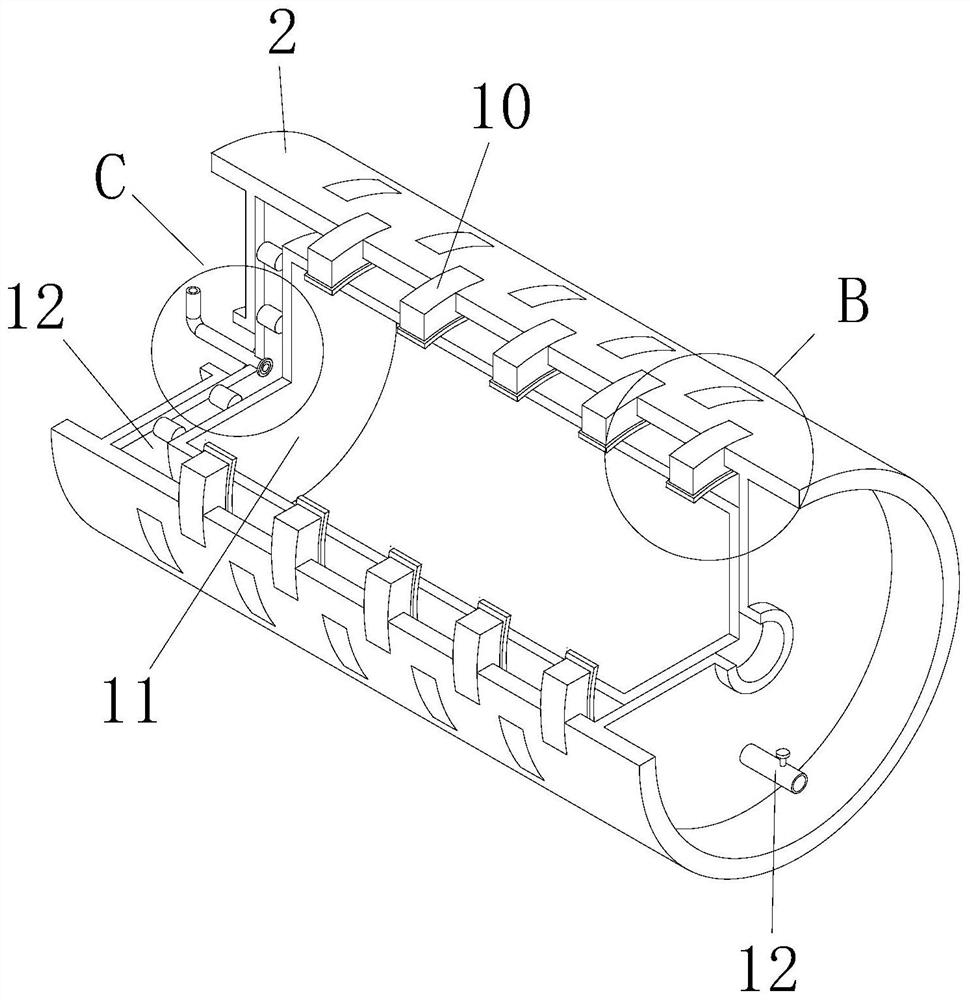

[0034] Embodiment: a kind of high-efficiency subgrade flattening device for road engineering construction, such as Figure 1-Figure 6As shown, it includes a pinch roller fixing frame 1 and a pinch roller body 2, the left and right ends of the pinch roller body 2 are respectively connected to the left and right inner walls of the pinch roller body 1 through rotating shafts, and the outer wall of the pinch roller body 2 is along the circumferential direction. Holes are evenly distributed, and each hole is provided with rolling sliders 10, and the inside of the pressure roller body 2 is provided with a weight-adjusting inner cylinder 11, and the top surfaces of the left and right ends of the pressure roller holder 1 are fixedly connected with Bracket 16, the top surface of the left end of the bracket 16 is fixedly connected with an air pump 17, and the left and right sides of the bottom end of the pressure wheel fixing frame 1 are respectively provided with two support links 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com