Vertical vibration reduction support and vibration reduction method thereof

A vertical and support technology, applied in the direction of building components, earthquake resistance, building type, etc., can solve the problem of single vibration absorption frequency, achieve high damping capacity and vertical deformation ability, overcome single vibration absorption frequency, and improve vibration reduction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

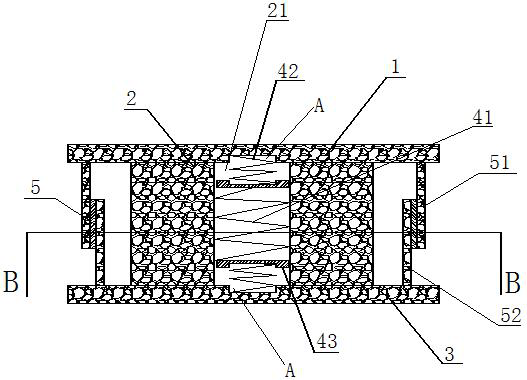

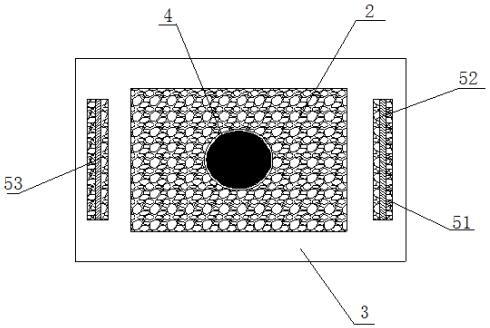

[0024] Combine below Figure 1~2 Embodiments of the present invention are described in detail.

[0025] The vertical vibration damping support includes an upper seat plate 1, a middle seat plate 2 and a lower seat plate 3 stacked and connected sequentially from top to bottom. It is characterized in that: the middle seat plate 2 is provided with a The multi-frequency vibration-absorbing component 4, the multi-frequency vibration-absorbing component 4 is in elastic contact with the upper seat plate 1 and the lower seat plate 3 respectively, and deforms synchronously with the relative vertical movement of the upper seat plate 1 and the lower seat plate 3, and the upper seat plate 1, the middle plate Both the seat plate 2 and the lower seat plate 3 have damping properties.

[0026] The above-mentioned vertical vibration-reducing support, the multi-frequency vibration-absorbing assembly 4 has multiple vibration-absorbing frequencies, can absorb vibrations of various frequencies, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com