Multi-layer nested parallel type coaxial rotary structure

A rotary structure, parallel technology, applied in the direction of structural connection, casing/cover/support, control of mechanical energy, etc., can solve the problems of use limitation, large axial size of the turntable body, etc., and achieve the effect of reducing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and preferred embodiments to make it easier to understand the scope of the invention in terms of those skilled in the art.

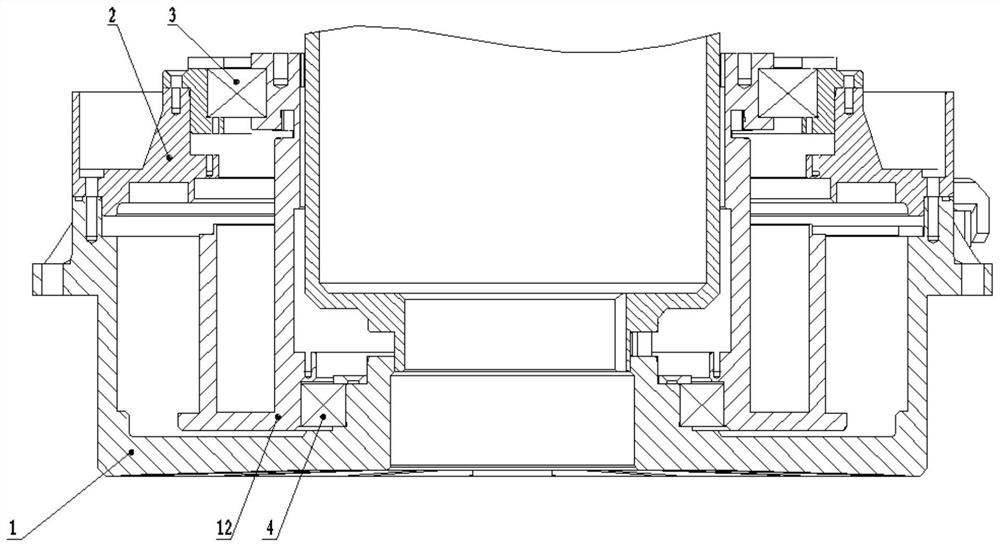

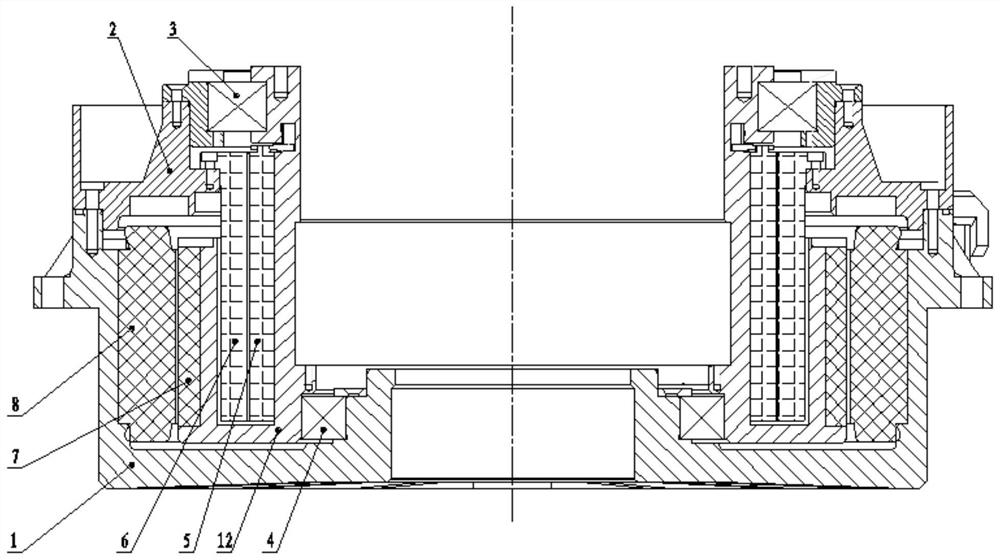

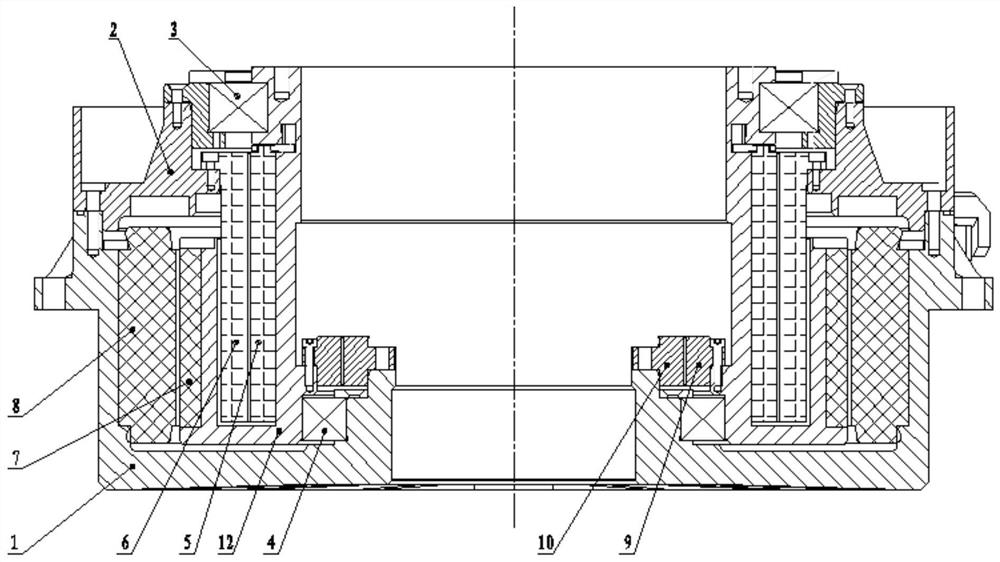

[0023] This embodiment provides a multilayer nested parallel coaxial swivel structure, and the coaxial rotary structure can be functionally realized from a multi-component coaxial rotation for driving, electrical connection, and position calculation, on the other hand. The structural dimensions of the multi-component coaxial turning body are minimized.

[0024] The multilayer nested parallel coaxial rotary structure includes: lower housing 1, upper casing 2, upper bearing 3, lower bearing 4, rotary connector, drive motor, solver, transfer drum 11, and spindle 12; The components that require coaxial rotation are rotary connector, drive motor, and solver; wherein the drive motor is used to drive, the rotary connector is used to implement an electrical connection, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com