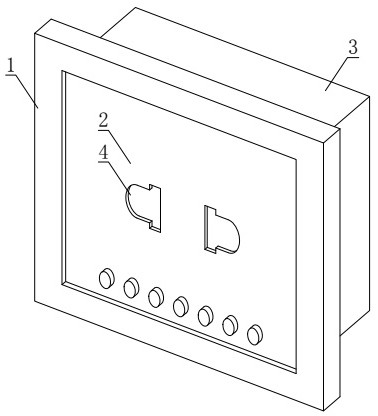

Anti-electric shock switch panel socket with automatic power-on and power-off functions and method thereof

An anti-shock switch, power-on and power-off technology, applied in the connection/disconnection of connection devices, circuits, electrical components, etc., can solve the problems of affecting the panel shell, high risk, easy electric shock, etc., to achieve the effect of easy repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

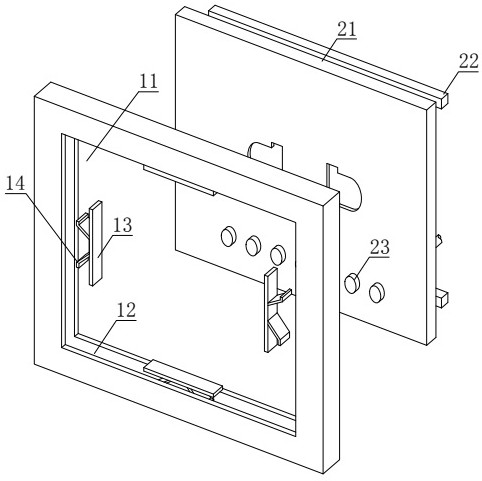

[0045] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing an electric shock-proof switch panel socket with automatic power on and off function, including the following steps:

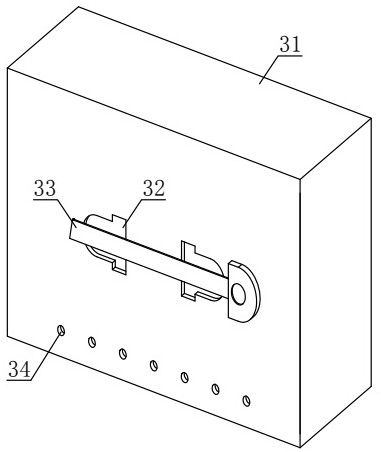

[0046] Step 1: Insert the plug into the jack 4, the plug contacts the hypotenuse of the trapezoidal plate 331 and drives the trapezoidal plate 331 to rotate around the shaft 333, so that the trapezoidal plate 331 is far away from the position of the through hole 32, the jack 4, the through hole 32 It communicates with the inside of the sleeve 371. When the plug enters the inside of the sleeve 371, it gradually squeezes the connecting piece 373 toward the connecting plate 365. When the plug drives the connecting piece 373 to touch the connecting plate 365, it can be connected smoothly. When the power is turned on, the plug can be charged;

[0047] Step 2: During the movement of the electrical connection piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com