Deep-well pump with filtering device

A technology of filtering device and deep well pump, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc. Low body thickness requirements and the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

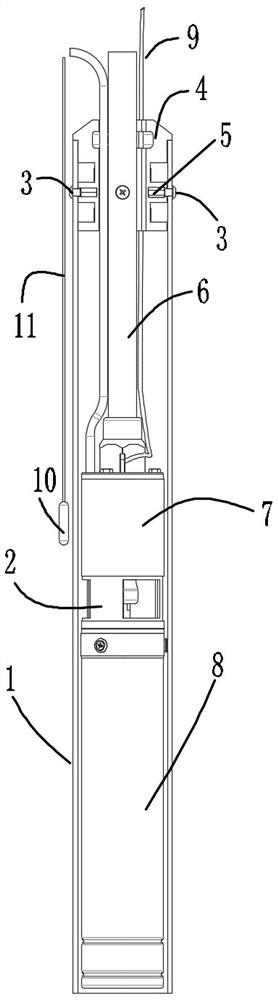

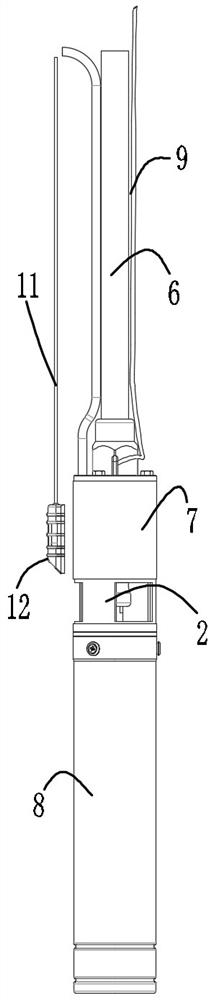

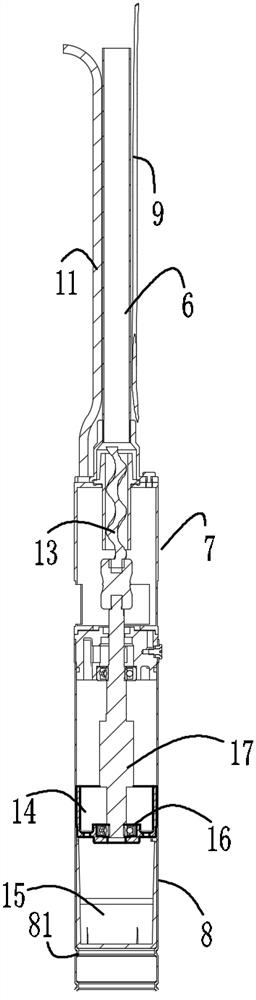

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] In the deep well pump with a filter device, the filter device is used to filter and block particles in the water body, especially to block particles in the process of sinking from the water surface. When the deep well pump is in use, it is suspended at the semi-deep position of the water source by the suspension rope 9, and the deep well pump will not be in contact with the bottom of the water source.

[0030] figure 1It is shown in the figure that the structure of the deep well pump includes a motor and a water lifting device, the motor and the water lifting device are connected by transmission, and the water lifting device is a screw 13. The motor is set in the machine barrel 8, the screw 13 is set in the upper barrel 7, the upper barrel 7 and the machine barrel 8 are coaxially connected and fixed through the frame-type coupling frame 2, and the power output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com