Combined heat and power generation unit coupling air energy storage compression heat supply system and optimized operation method

A technology of cogeneration unit and air energy storage, applied in design optimization/simulation, computer-aided design, electrical digital data processing, etc., can solve problems such as high profitability, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

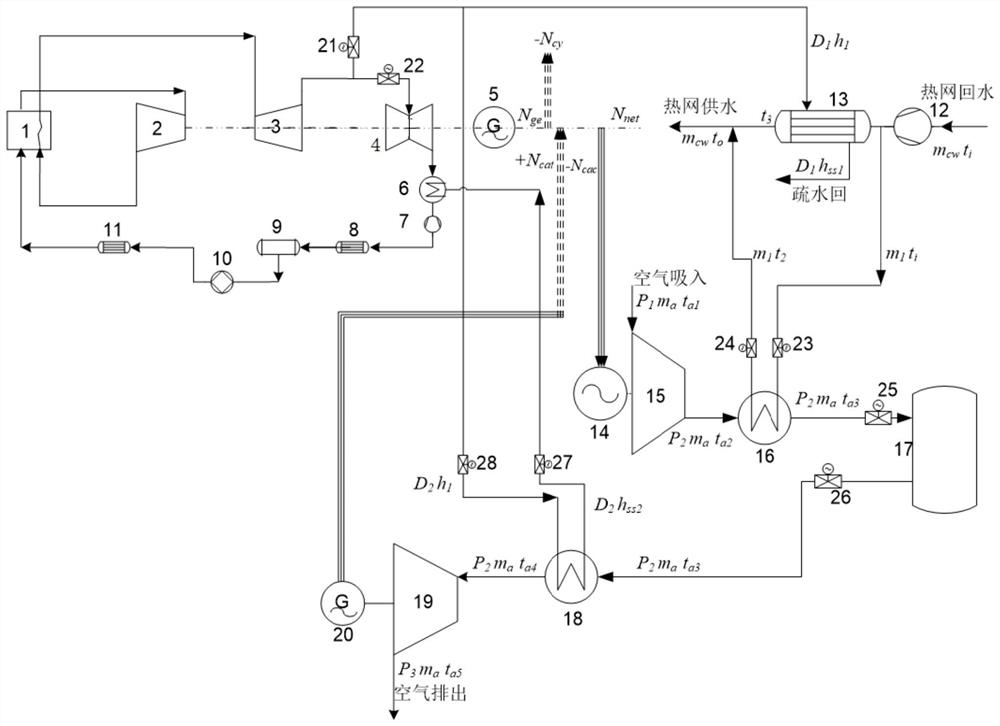

[0081] In order to clearly describe the implementation process of the optimal operation method of the combined heat and power unit coupled with the air energy storage compression heating system proposed by the present invention, a certain cogeneration unit is added with a compressed air energy storage system as an example, figure 1 It is a schematic diagram of the system of this embodiment.

[0082] The combined heat and power unit adopts the method of extracting steam from the middle exhaust to the heat network heater to heat the circulating water for heating and supplying heat to the outside. At the same time, it implements the zero-output heating transformation of the low-pressure cylinder. Two heating modes.

[0083] In order to improve the peak shaving capacity, the combined heat and power unit has added a compressed air energy storage system.

[0084] see figure 1 , the new steam from the outlet of boiler 1 enters the high-pressure cylinder 2 to do work, and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com