Non-isolated three-phase rectification converter and control method thereof

A three-phase rectification, non-isolated technology, which is applied in the directions of converting DC power input to DC power output, AC power input to DC power output, and irreversible AC power input to DC power output, etc., which can solve inappropriate, Problems such as large loss and many devices in the conduction path achieve the effects of reduced limitation, reduced control difficulty, and low loop conduction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

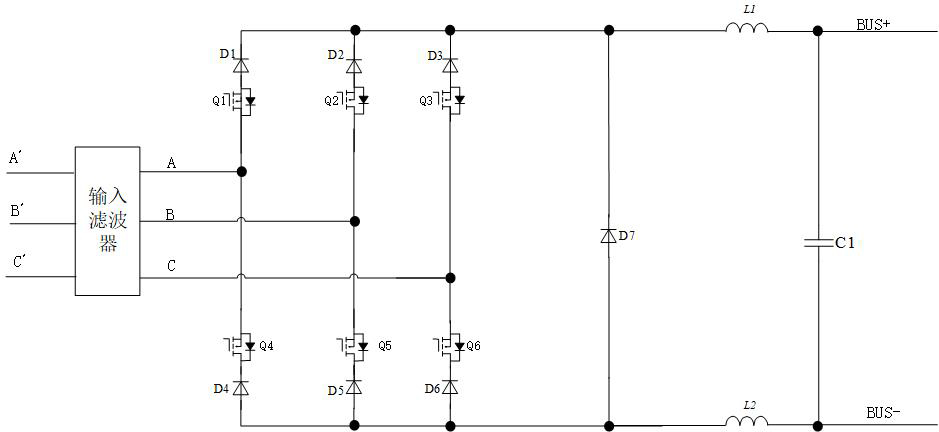

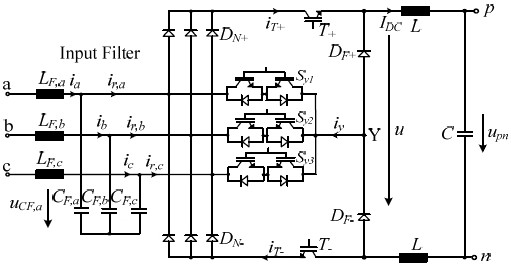

[0040] Such as Figure 4 As shown, this embodiment proposes a non-isolated three-phase rectifier converter, an input rectifier bridge group, a step-down switch unit and an energy storage freewheeling unit; the input end of the input rectifier bridge group is connected to an external three-phase three-wire The power supply (or the output end of a three-phase three-wire power supply with a filter) is connected, the output end of the input rectifier bridge group is connected to the input end of the step-down switch unit, and the output end of the step-down switch unit is connected to the input end of the step-down switch unit. Energy storage freewheeling unit connection. The external three-phase three-wire power supply includes A phase, B phase and C phase. The input rectifier bridge group includes first to third rectifier bridges FB1 to FB3, the first to third rectifier bridges are diode full-bridge rectifier bridges, and the interior is composed of four diodes (for the conveni...

Embodiment 2

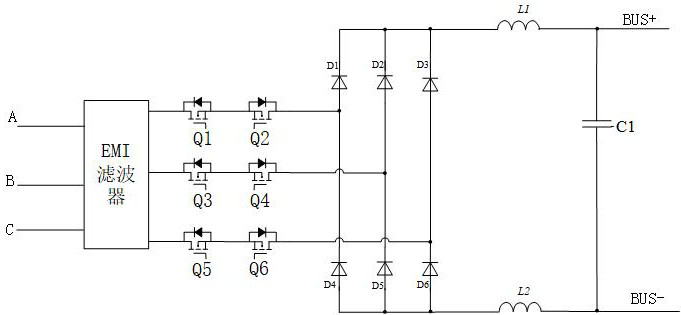

[0069] Such as Figure 14 As shown, this embodiment proposes a modified and modified implementation of the non-isolated three-phase rectifier converter in Embodiment 1. In this embodiment, a non-isolated three-phase rectifier converter is proposed, including at least two three-phase rectifier converters as described in Embodiment 1 connected in parallel, and the switching tubes between each three-phase rectifier converter are driven to Interleaved mode works. In order to make the AC input current easier to achieve continuous.

[0070] Through the aforementioned "high" and "middle" drive signal control methods, at least two (denoted as N) parallel-connected three-phase rectifier converters can be controlled respectively, and the switching tube cycle of N parallel-connected three-phase rectifier converters The internal working phase differs by 1 / N high-frequency switching cycles; therefore, the current at the AC input terminal can form a multi-phase interleaved parallel connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com