A modular automatic detachable escape device

A technology of automatic separation and escape device, applied in the field of safety, can solve the problems of low reliability, high speed, immersion in water, etc., and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and examples. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

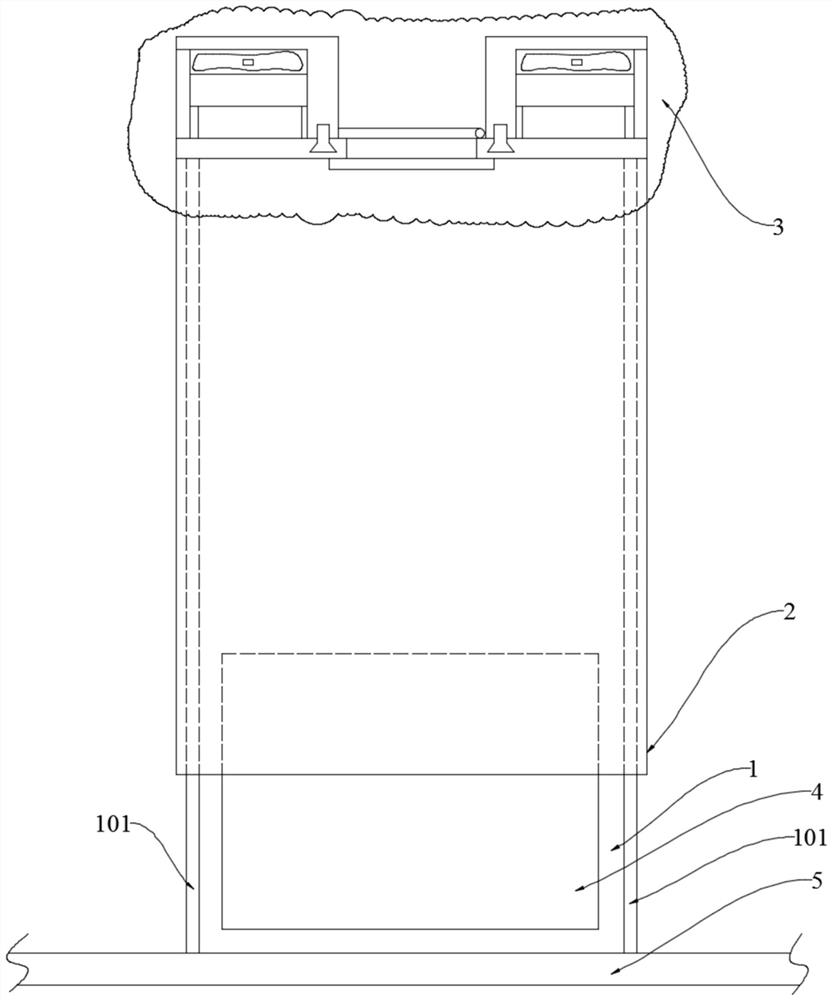

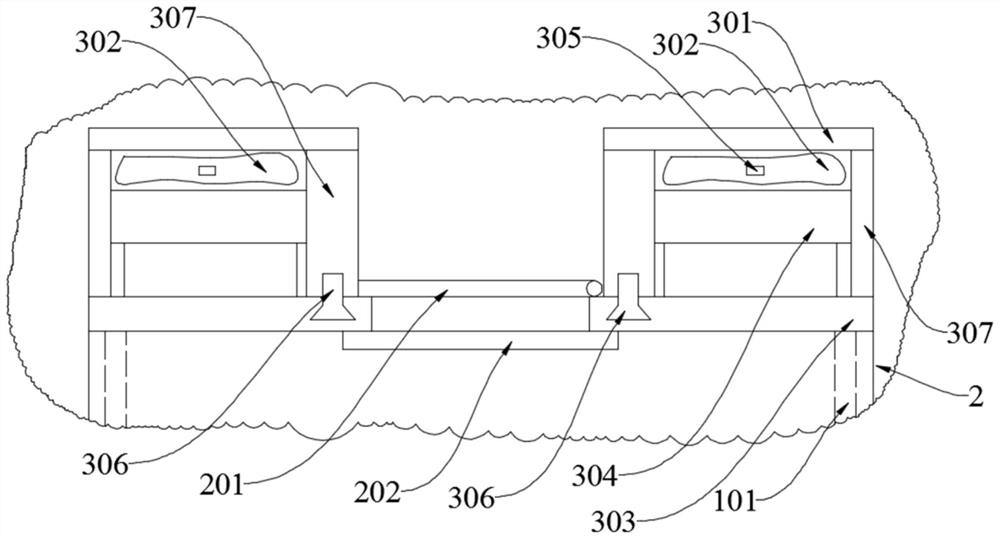

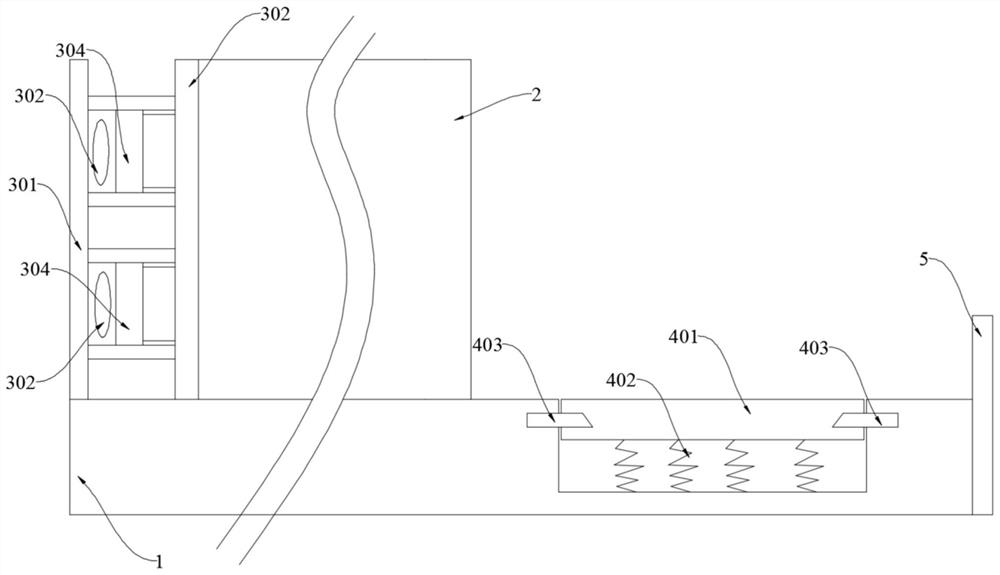

[0023] A modular self-separating escape device includes a support base 1, an escape cabin 2 and an ejection module 3. The support base 1 is provided with a slide rail 101, and the escape cabin 2 is installed on the slide rail 101 and can be installed on the slide rail 101. Sliding along the slide rail, the ejection module 3 includes a base 301, an inflation air bag 302, a bearing plate 303, a piston 304 and a gas generator 305. The base 301 is fixed on the support base 1, and the base 301 faces the escape. A plurality of cylindrical air chambers 307 are provided on one side of the cabin 2, each cylindrical air chamber 307 is provided with a piston 304, and an inflation air bag 302 is provided between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com