Industrial solid waste comprehensive treatment system and treatment method

A technology for industrial solid waste and treatment systems, applied in manufacturing tools, presses, packaging, etc., can solve the problems of increasing the probability of loosening of the cloth compression block, the ejection of the cloth compression block out of the equipment, and excessive scratching, etc. The probability of loosening and falling, the effect of reducing the probability of loosening, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

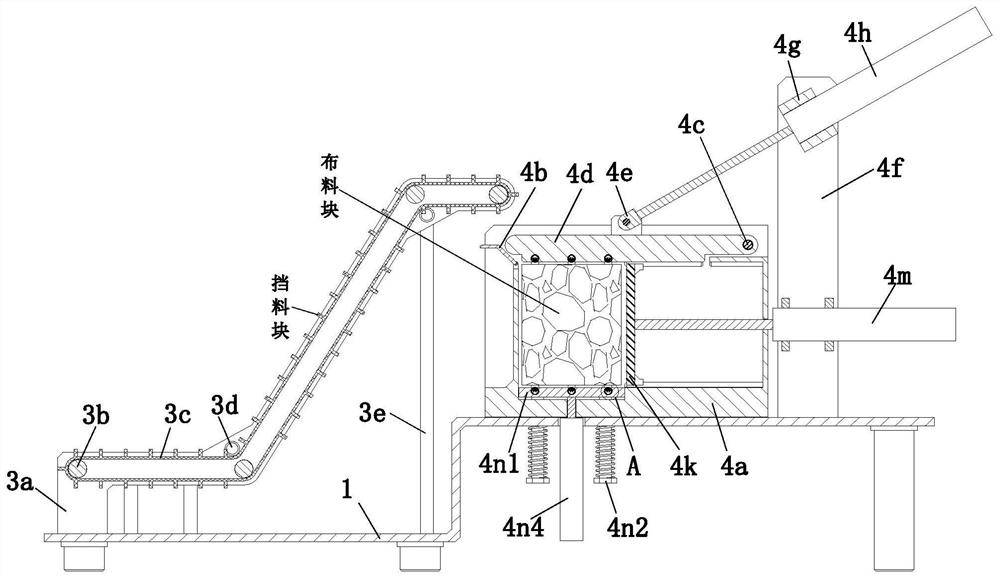

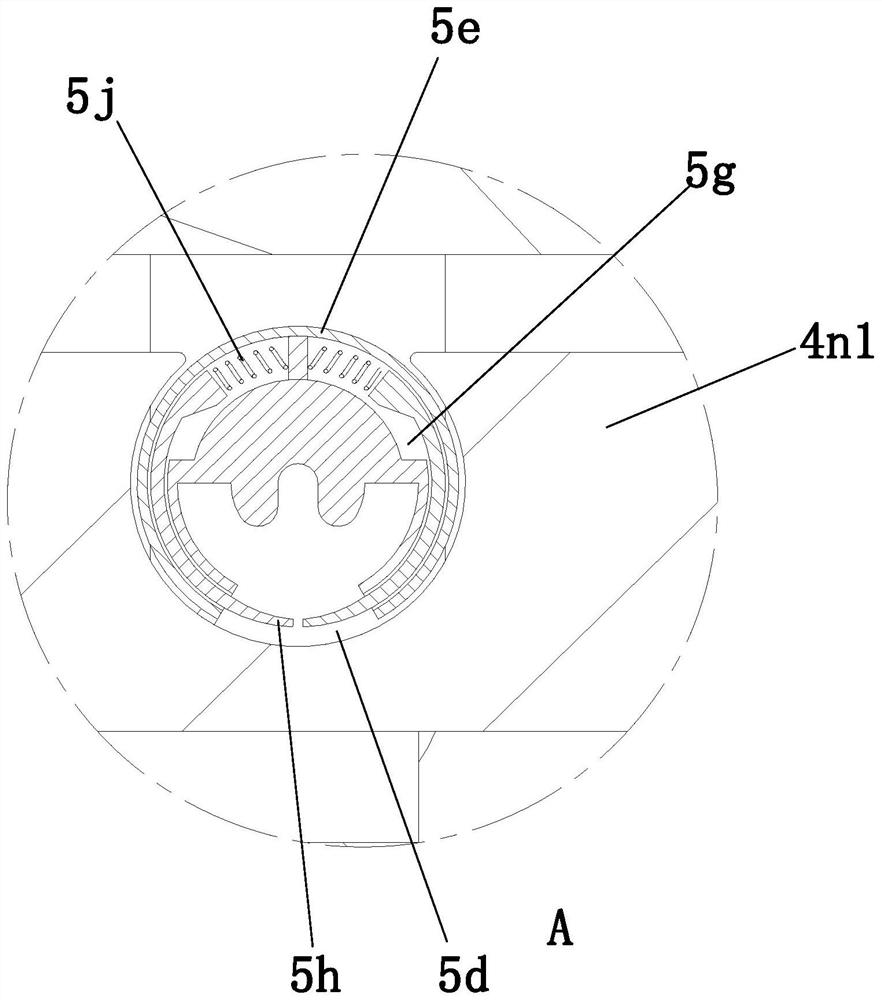

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0032] An industrial solid waste comprehensive treatment system, comprising an installation base plate 1, support feet 2, a conveying mechanism 3, a compression mechanism 4 and a packaging mechanism 5, the lower end of the installation base plate 1 is uniformly equipped with multiple sets of support feet 2, and the installation base plate 1 A conveying mechanism 3 is installed on one side upper end of one side, a compression mechanism 4 is installed on the other side upper end of the installation base plate 1, and a packaging mechanism 5 is installed in the compression mechanism 4 .

[0033]Described conveying mechanism 3 comprises elevating frame 3a, conveying rotating shaft 3b, conveyer belt 3c, guiding rotating shaft 3d, supporting rod 3e and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com