Revit-based fabricated shear wall automatic modeling method and system

A technology of automatic modeling and shear wall, applied in the field of building information model information, which can solve the problems of huge, complex and changeable workload and tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

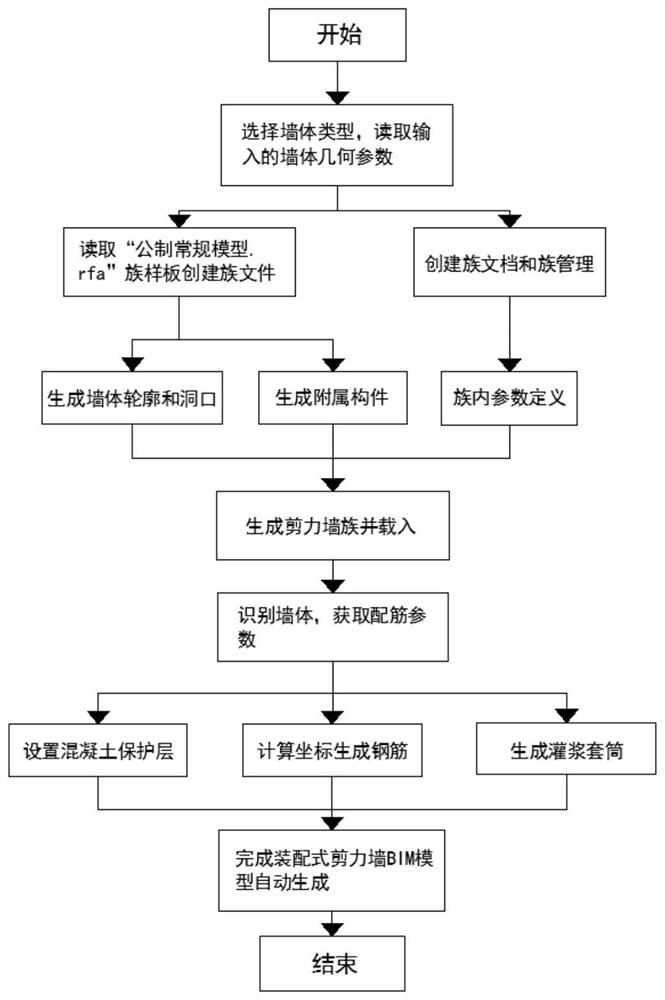

[0036] refer to Figure 1-2 , a method for automatic modeling of prefabricated shear walls based on Revit, including the following steps:

[0037] Step 1. Get the geometric parameters of the wall through the Form window: according to the selected prefabricated shear wall wall type, enter the geometric parameters in the form, convert the input data into units and store them;

[0038] Step 2, create a family file: use the method in the Revit API development tool to get the family template file from the family template folder, and create a family document and manage the family management for all editing behaviors in the family;

[0039] Step 3, wall profile and opening generation: In the created family template file, according to the obtained wall geometric parameters, the solid wall profile and the opening of the shear body are generated through the stretching method in the Revit API development tool, through The graphic element connection method in the RevitAPI development too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com