High-speed filling machine

A filling machine, high-speed technology, applied in the field of pharmaceutical packaging equipment, can solve the problems of difficulty in maintaining high-speed filling state, single running trajectory of filling components, and reducing the continuity of filling production, so as to improve the uniformity of feeding and dispersion, The effect of reducing the need for manual feeding and improving the balance of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following combined with the accompanying drawings Figure 1-Figure 13 The application is described in further detail.

[0067] The embodiment of the present application discloses a high-speed filling machine.

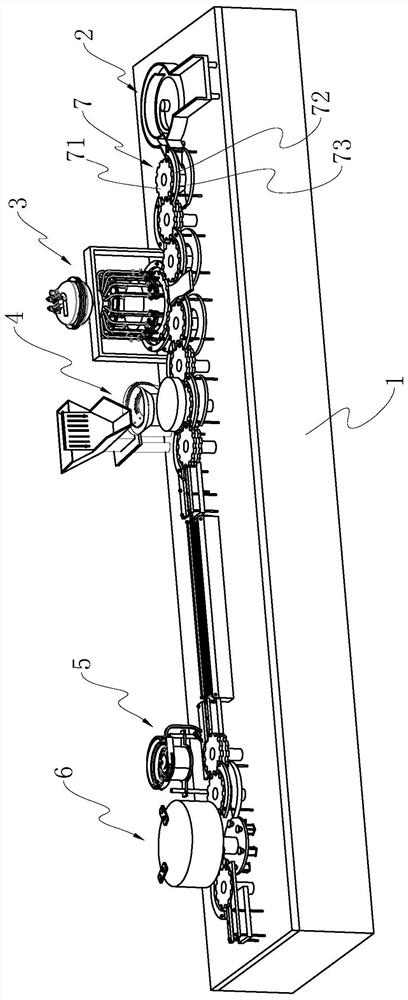

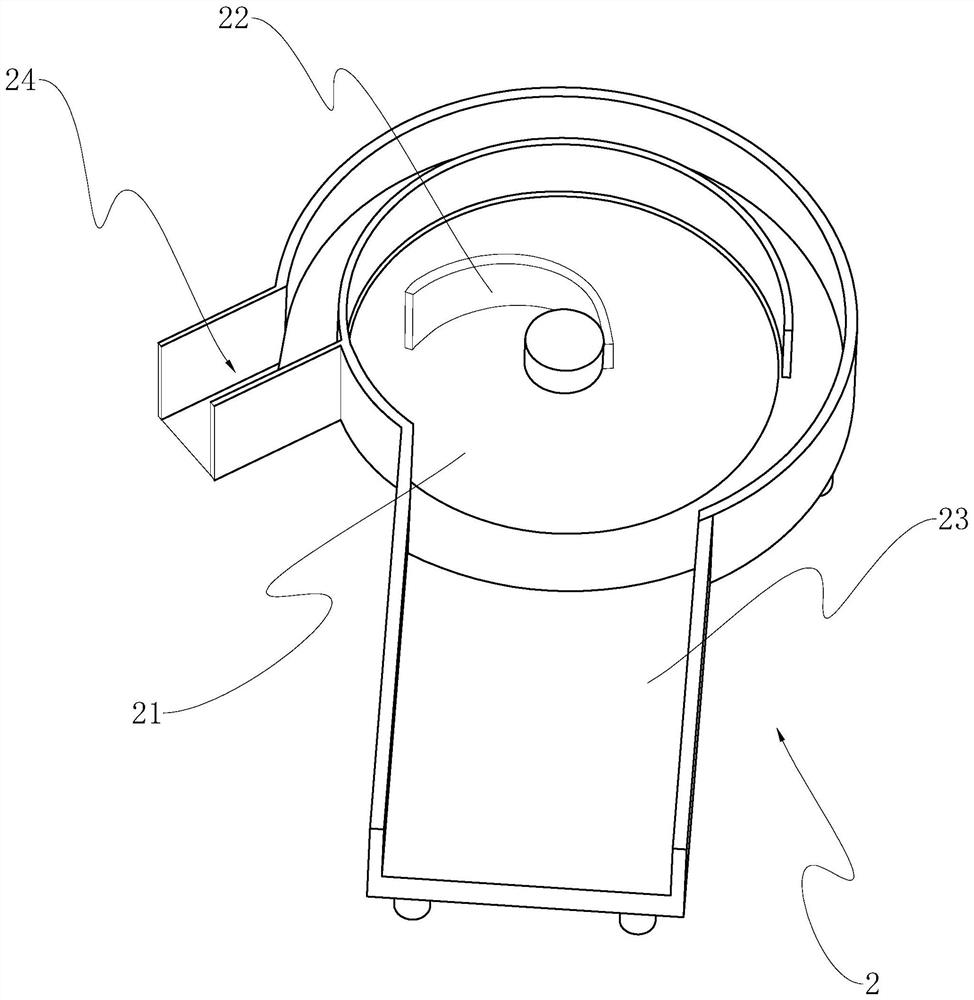

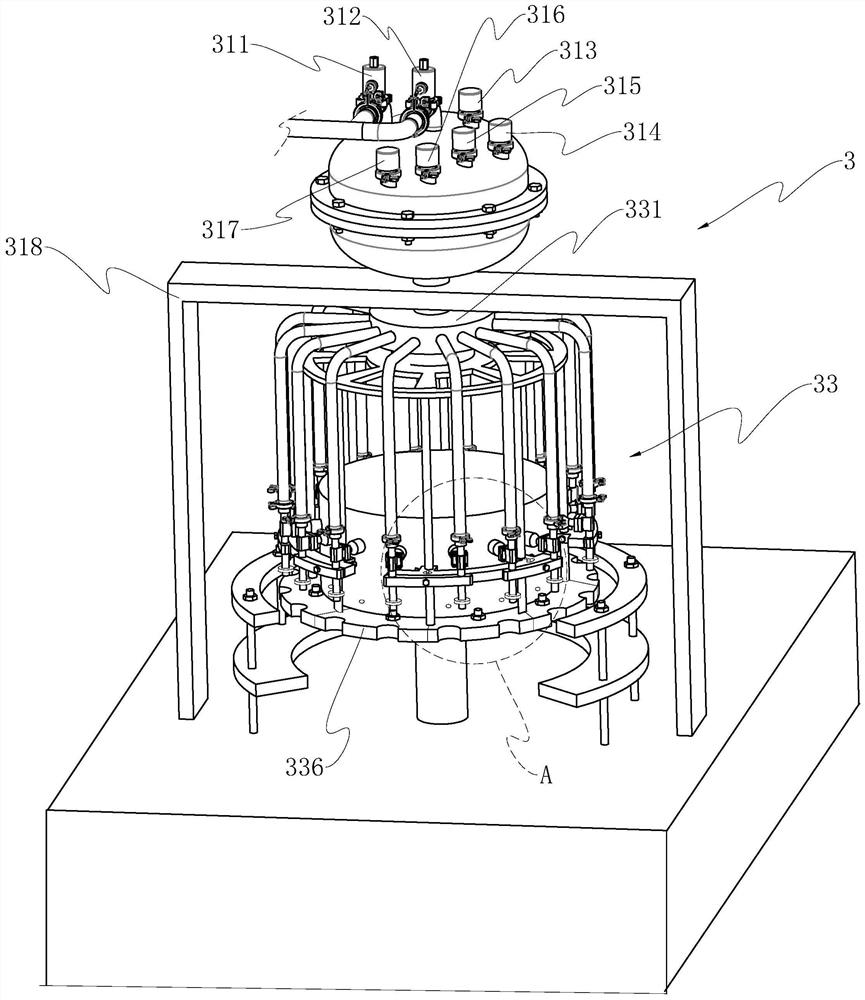

[0068] refer to figure 1 , a high-speed filling machine, including a workbench 1 and a control host, the workbench is provided with a bottle unscrambling assembly 2, a filling machine 3, a plugging assembly 4, a capping machine 5 and a capping machine in sequence along the running path of the bottle body 6. Each process device is connected by a bottle transport assembly 7. The bottle transport assembly 7 includes a bottle transport turntable 71 and a bottle transport guide plate 72 arranged on one side of the bottle transport turntable. The bottle transport guide plate 72 is provided with a bottle inlet and outlet The gap of the bottle is also provided with a clamping groove on the circumference of the bottle transporting turntable 71, the bottle transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com