Cleaning control method of extractor hood and extractor hood

A technology for range hoods and control methods, applied in cleaning methods and utensils, oil fume removal, chemical instruments and methods, etc., can solve problems such as wasting time, no cleaning methods, and easily damaged parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

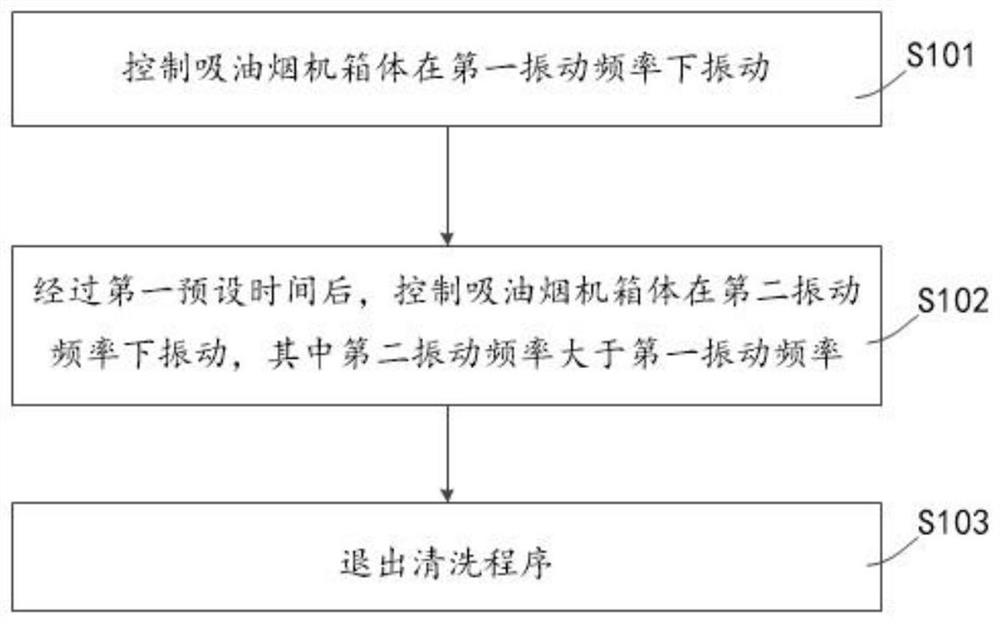

[0035] see figure 1 It shows a cleaning control method of a range hood according to the present invention, which includes the following steps:

[0036] Step S101, controlling the cabinet of the range hood to vibrate at the first vibration frequency;

[0037] Step S102, after the first preset time, control the cabinet of the range hood to vibrate at a second vibration frequency, wherein the second vibration frequency is greater than the first vibration frequency;

[0038] Step S103, exit the cleaning program.

[0039] The present invention proposes a cleaning control method for range hoods. When the range hood cabinet is controlled to vibrate at the first vibration frequency, the oil in the range hood cabinet gradually gathers from the state of being scattered and flat, and within the first preset time Form the first pattern, and then control the range hood cabinet to vibrate at the second vibration frequency, so as to control the oil stain on the range hood cabinet from the ...

Embodiment 2

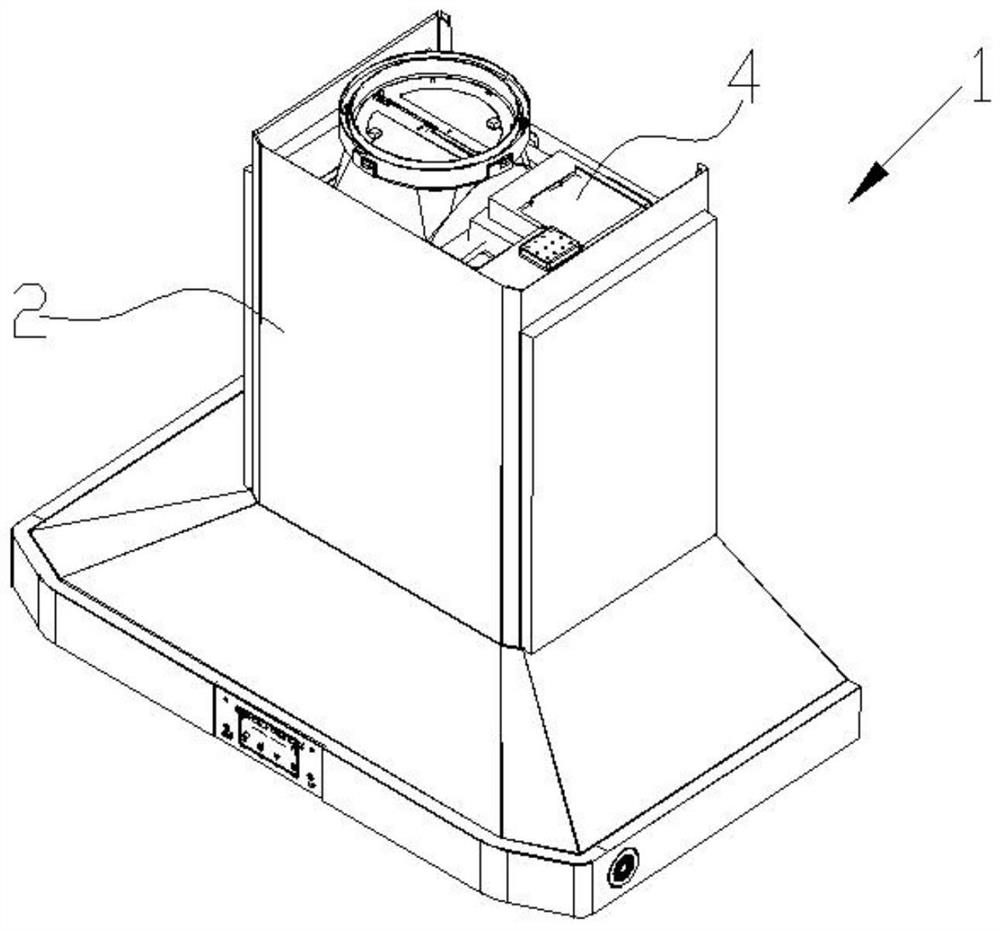

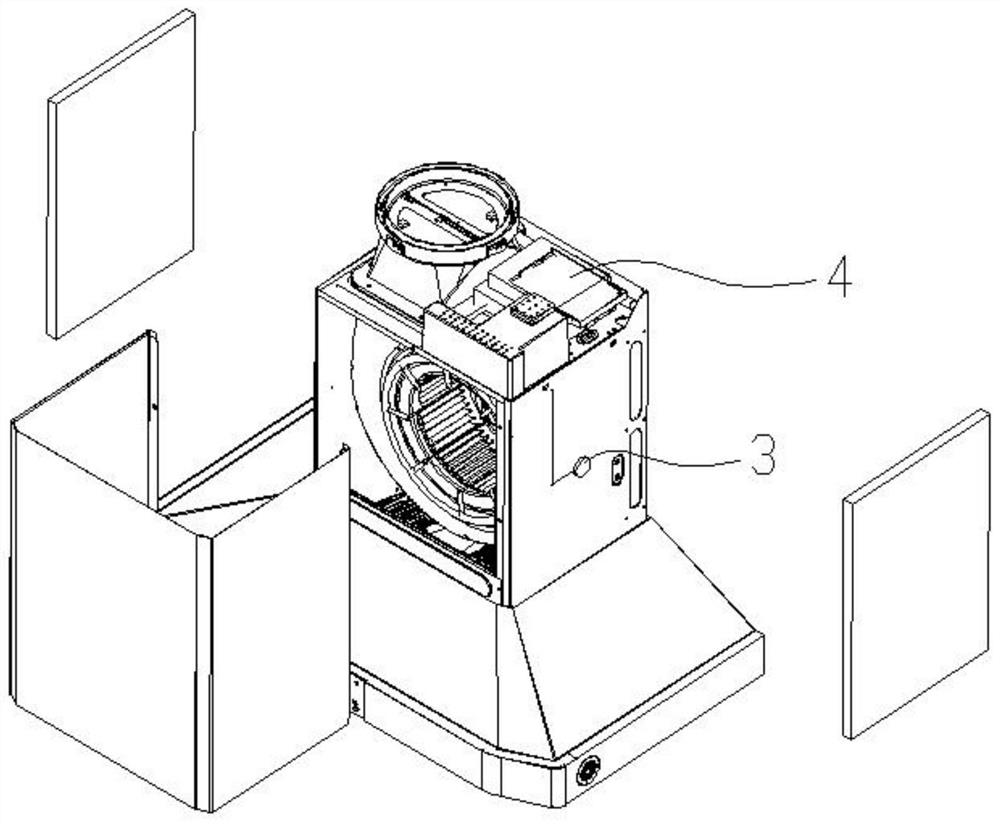

[0061] Such as figure 2 , 3 , a range hood 1, including a box body 2, a vibrator 3 and a vibration signal device 4 are arranged on the box body 2, the vibrator 3 is electrically connected to the vibration signal device 4, and the vibration signal The vibrator 4 controls the vibration frequency generated by the vibrator 3 .

[0062] The subject of the present invention is a range hood 1. The vibration signal device 4 controls the vibrator 3 to generate vibrations of different frequencies, so that the oil in the range hood 1 gathers to form oil droplets, and the oil droplets flow down to the oil cup under the action of gravity. . Effectively remove oil from the range hood cabinet.

[0063] It also includes a fume collection hood and an oil cup, the fume collection hood is arranged under the box body 2, and the oil cup is arranged under the fume collection hood.

[0064] The box body 2 is made of metal sheet.

[0065] Described box body 2 comprises front plate, back plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com