Pintle injector for liquid rocket engine

A liquid rocket and engine technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of poor atomization and mixing characteristics, achieve improved atomization and mixing characteristics, good atomization effect, The effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

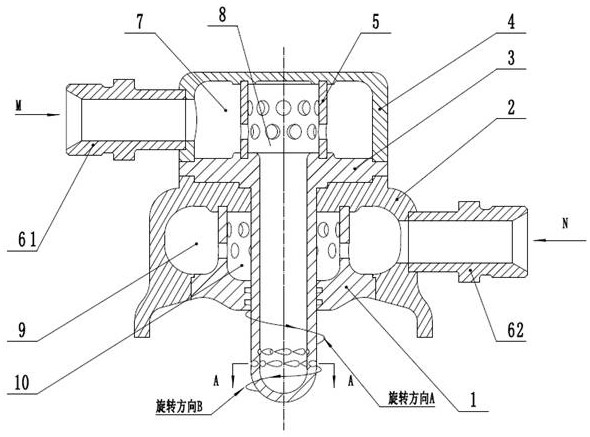

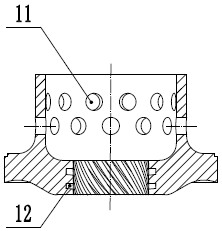

[0042] to combine Figure 1-Figure 3 As shown, the pintle injector for liquid rocket motor provided by this embodiment includes:

[0043] The pintle body 3 is configured as a hollow tubular structure, and the pintle body 3 is suitable for passing through the first propellant;

[0044] The bottom cover 1 is sleeved on the outside of the pintle body 3, and the inside of the bottom cover 1 is suitable for passing the second propellant;

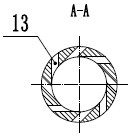

[0045] One end of the pintle body 3 is provided with several tangential holes 13 around, and a plurality of swirl holes 12 are arranged at the fitting position of the bottom cover 1 and the pintle body 3; The second propellant ejected from 12 is opposite to the rotation direction of the first propellant ejected from the tangential hole 13 and collides and mixes with each other.

[0046] preferably, with figure 1Taking the angle of view of the pintle body 3 as an example, the pintle body 3 is constructed as a hollow tubular structure, and its u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com