Three-dimensional mask beneficial to rapid and automatic production and production method thereof

A mask, three-dimensional technology, applied in the field of medical and sanitary products, can solve the problems of time-consuming and labor-intensive, time-consuming, unfavorable continuous and rapid production, etc., and achieve the effects of improving production efficiency, prolonging service life, and shortening production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

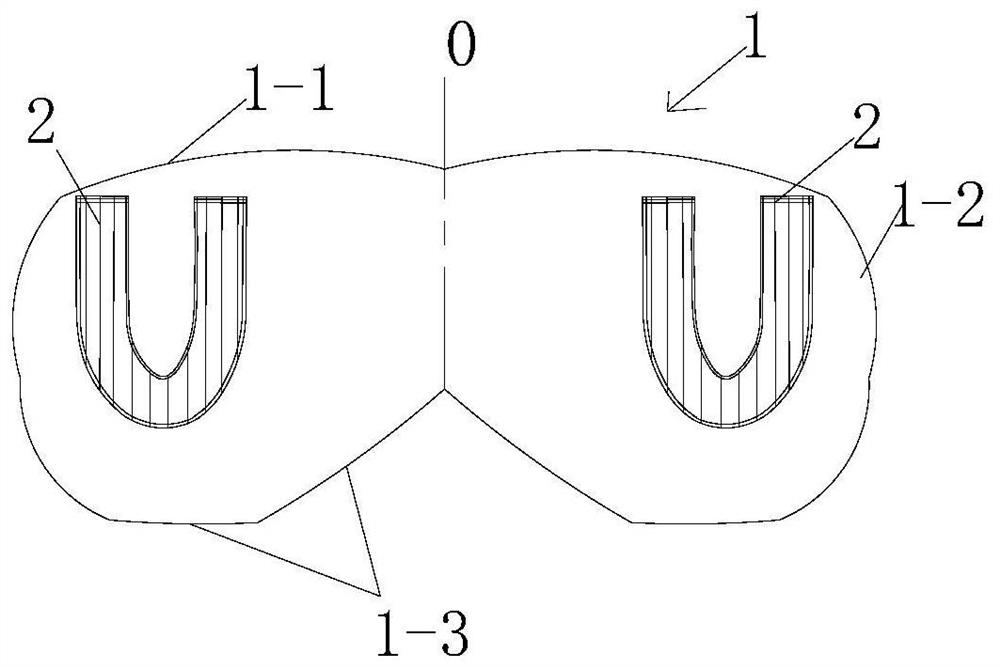

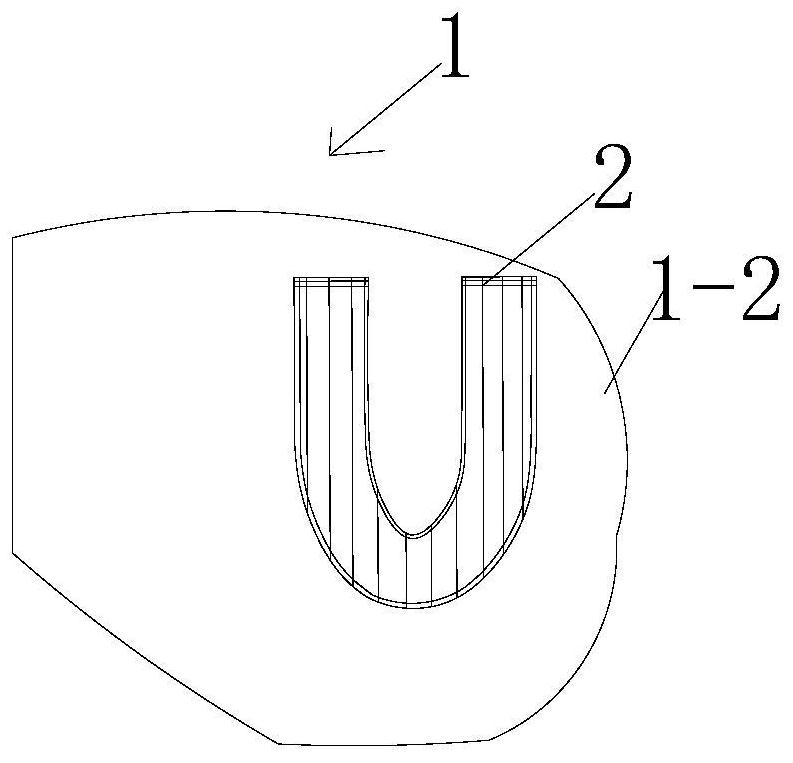

[0029] Such as Figures 1 to 4 As shown, the disposable protective mask of the present embodiment includes: after the mask body 1 is expanded, the left and right lobe 1-1 and the right lobe 1-2 are symmetrically distributed, and the elastic band 2 is symmetrically arranged on the outside of the left and right lobe. On the side, the elastic band 2 is a U-shaped body, and the opening 2-1 of the U-shaped body is connected to the edges of the left and right flaps; The lines of symmetry are parallel; the elastic belt 2 includes: a pair of laminated non-woven fabrics, a plurality of elastic bands or elastic spandex filaments or shrinkable films 3 distributed in the pair of non-woven fabrics in a transverse direction.

[0030] After the left and right flaps of the mask body 1 are folded in half along the above-mentioned line of symmetry, the herringbone bottoms 1-3 of the left and right flaps are connected by ultrasonic welding.

[0031] A pair of heads 2-1 of the U-shaped body are ...

Embodiment 2

[0045] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0046] The elastic belt layer 2 is elastic non-woven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com