A press-holding mechanism for crankcase leak detection and a crankcase leak detection device

A pressing mechanism and crankcase technology, which is applied in the direction of machine/structural component testing, measuring devices, workpiece clamping devices, etc., can solve problems such as inability to hold, occupy space above the holding point, etc., and achieve convenient operation, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

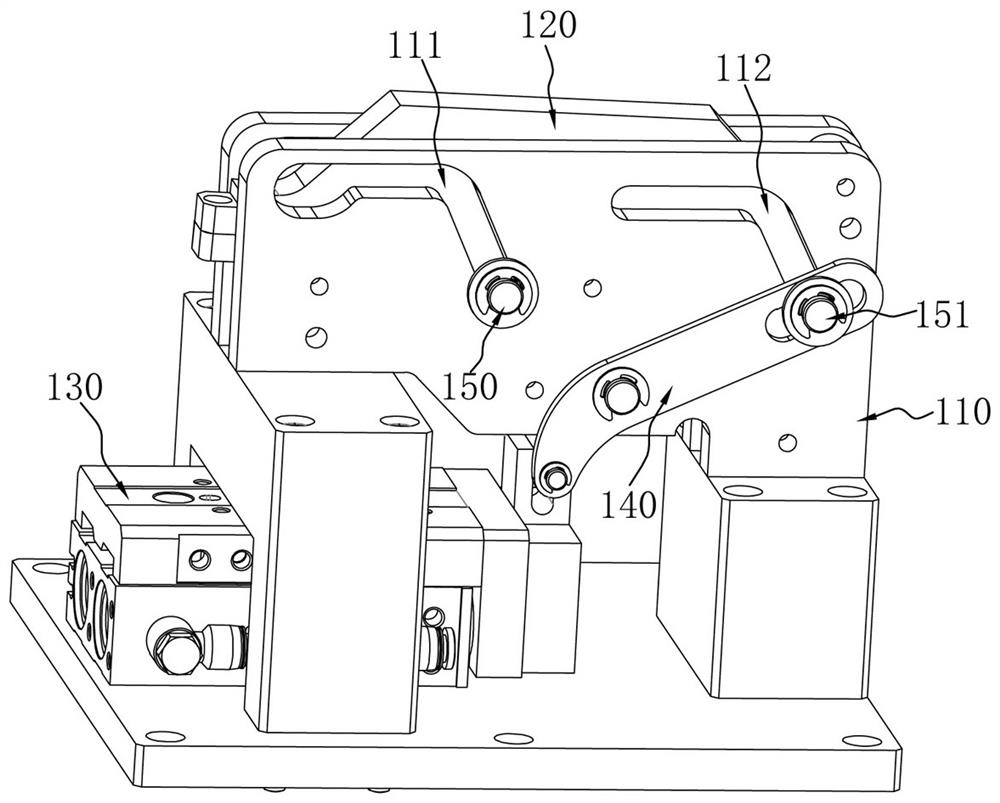

[0042] Please refer to Figure 1-Figure 5 , the invention discloses a clamping mechanism for crankcase leakage detection, the crankcase has a clamping point, including:

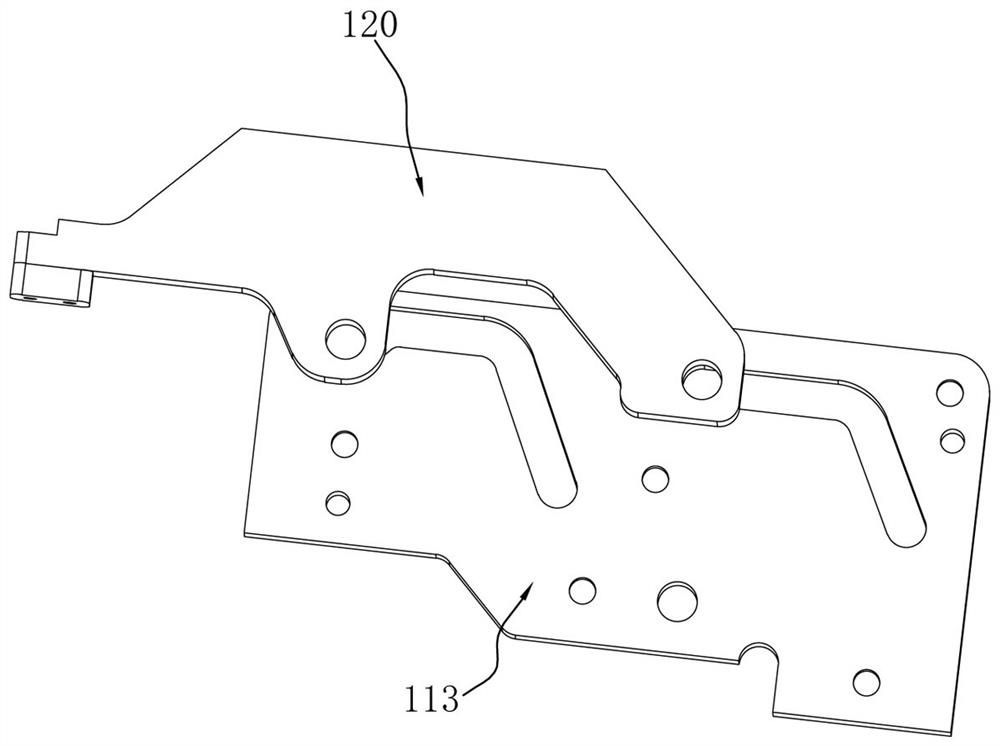

[0043] a fixed seat 110, which is fixedly connected with the crankcase 200;

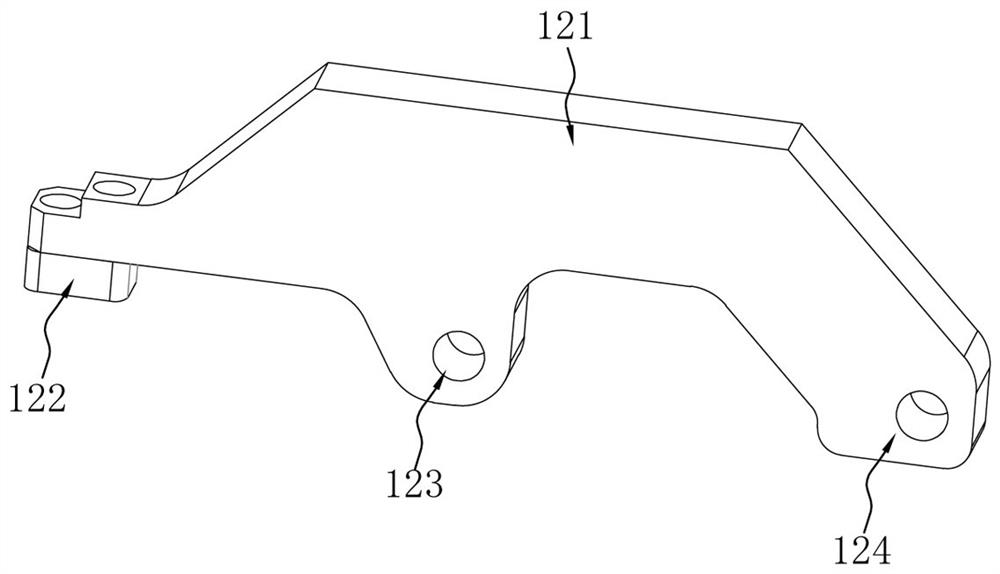

[0044] A pressing block 120, which is movably connected with the fixing seat 110, and the pressing block 120 has a holding portion 122;

[0045] Rotating member 140, which has a first hinged part 141 and a second hinged part 142, the first hinged part 141 is hinged with the pressing block 120, and the second hinged part 142 is hinged with the fixed seat 110;

[0046] The pressing block 120 has a first position and a second position, and turning the rotating member 140 makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com