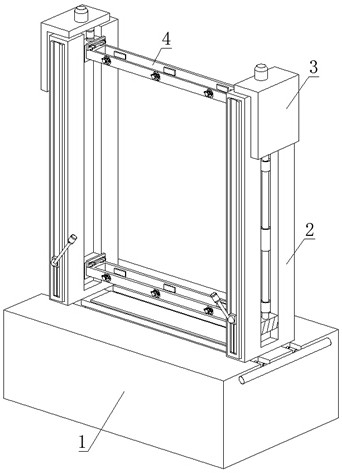

An all-aluminum lightweight container board performance testing device and method of use

A container board and lightweight technology, which is applied in the field of performance testing devices for all-aluminum lightweight container boards, can solve problems such as low degree of automation and difficulty in testing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

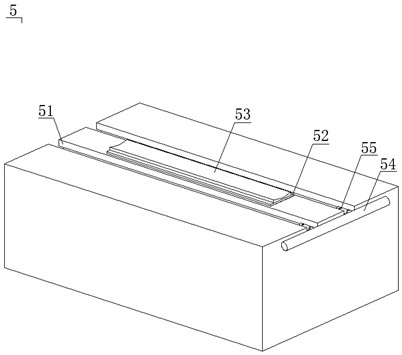

[0040] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for using a device for testing the performance of an all-aluminum lightweight container board, including the following steps:

[0041] Step 1: load two groups of clamping mechanisms 4 between two groups of side mechanisms 2, wherein one group is placed on one end of the side mechanism 2, and the other group is placed on the other end of the side mechanism 2. The detected container board is put into the inside of the clamping groove 42, and is fixed by a threaded rod 46;

[0042] Step 2: After fixing with the threaded rod 46, use the mutual cooperation between the positioning plate 455 and the push rod 44, so that the stability maintenance mechanism 45 gives an upward force to the container board to strengthen the installation of the container board;

[0043] Step 3: Use the two-way telescopic rod 25 to make the electromagnetic block 26 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com