H-shaped sealing device for split of small steam turbine of water feeding pump of thermal power plant

A technology of small steam turbines and sealing devices, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of aging and failure of sealing strips, troublesome installation of sealing strips, etc., to improve the tightness of facets, save management costs, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

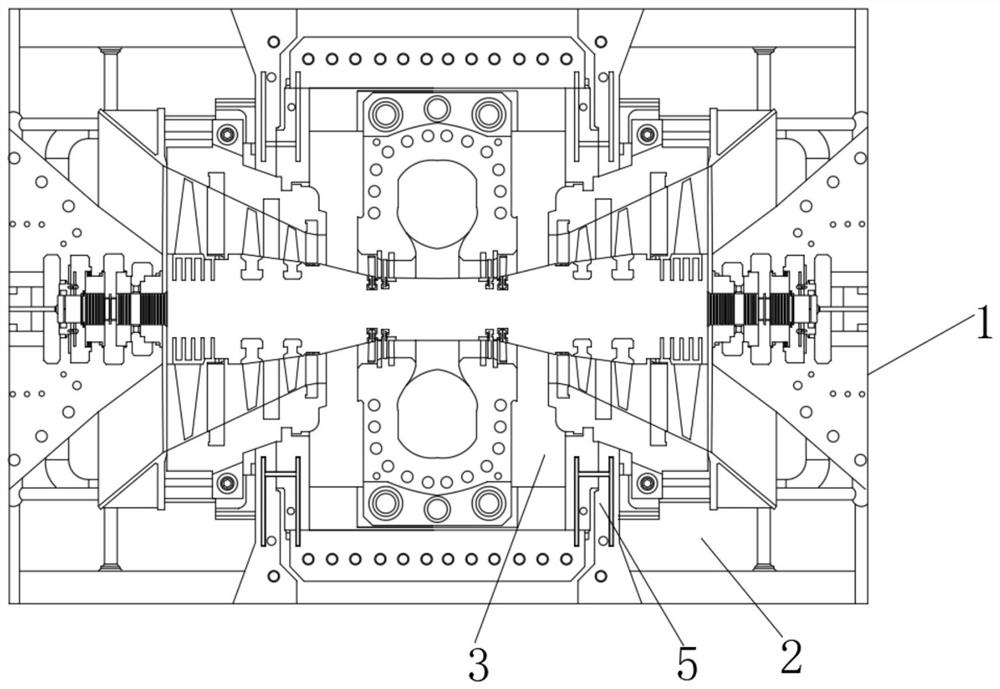

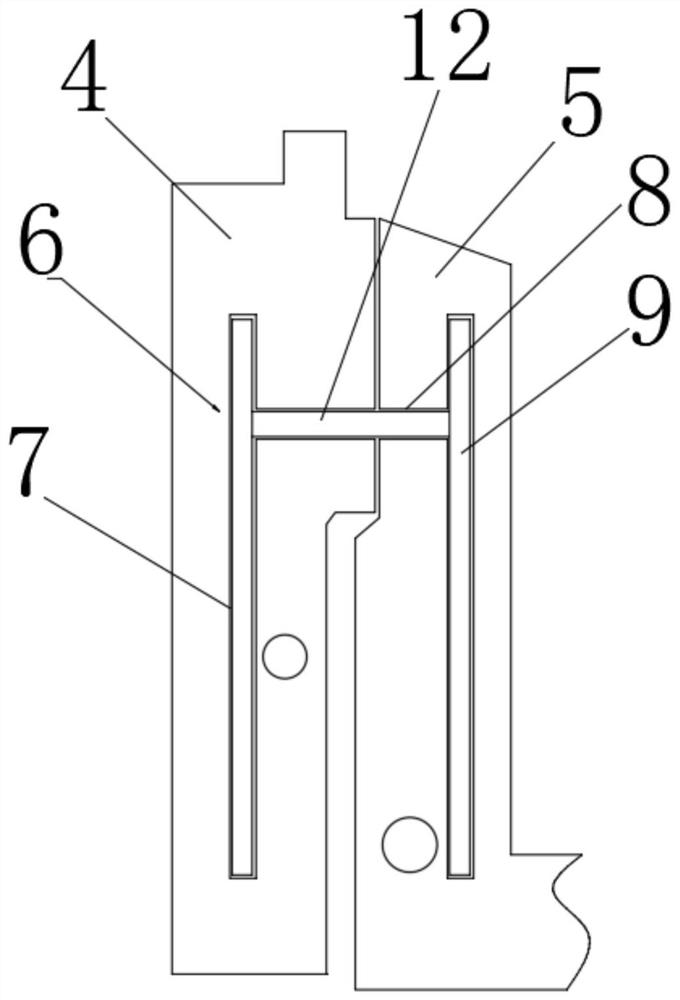

[0025] see Figure 1-2 , the present invention provides a technical solution: a split-face H-shaped sealing device for a small steam turbine in a thermal power plant feed water pump, including a main body 1, an exhaust chamber 2 is provided inside the main body 1 near a corner, and an exhaust chamber 2 is provided inside the main body 1 near the middle There is a steam inlet chamber 3, the steam inlet side wall 4 is arranged on both sides of the steam inlet chamber 3, and the exhaust side wall 5 is arranged on the side wall of the exhaust chamber 2 near both sides, the steam inlet side wall 4 and the steam exhaust side wall 5 A sealing mechanism 6 is provided on it.

[0026] see figure 2 , the sealing mechanism 6 includes a vertical groove 7, a horizontal groove 8 is opened on the surface of the steam inlet side wall 4 and the steam exhaust side wall 5 near the vertical groove 7, and a limit bar 9 is arranged inside the vertical groove 7, and the upper end of the limit bar 9...

Embodiment 2

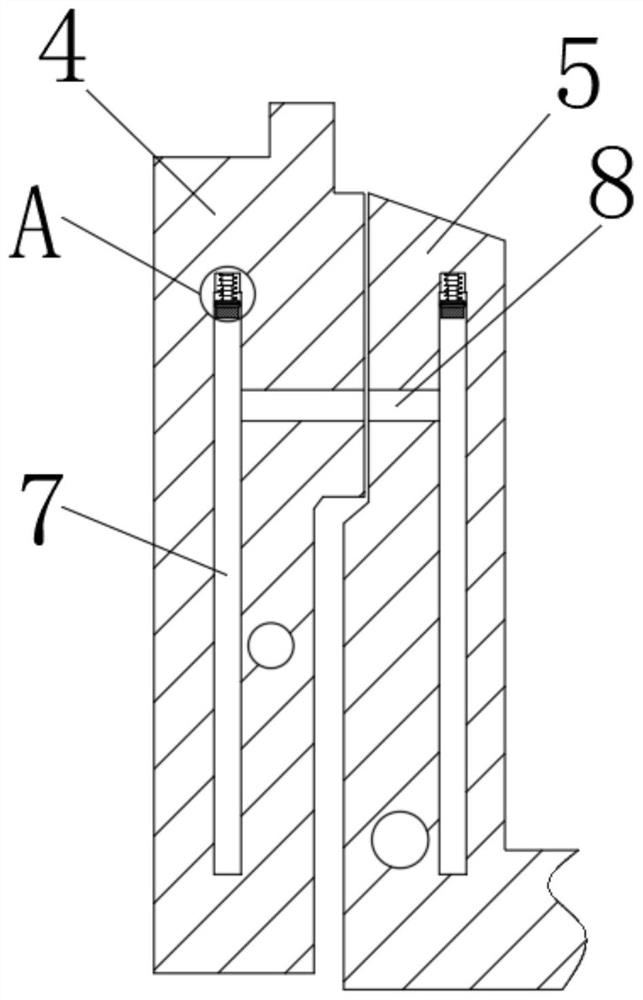

[0029] see Figure 3-5 , the present invention provides a technical solution: a split-face H-shaped sealing device for a small steam turbine in a thermal power plant feed water pump, including a main body 1, an exhaust chamber 2 is provided inside the main body 1 near a corner, and an exhaust chamber 2 is provided inside the main body 1 near the middle There is a steam inlet chamber 3, the steam inlet side wall 4 is arranged on both sides of the steam inlet chamber 3, and the exhaust side wall 5 is arranged on the side wall of the exhaust chamber 2 near both sides, the steam inlet side wall 4 and the steam exhaust side wall 5 A sealing mechanism 6 is arranged on the top, a movable groove 13 is provided on the inner side wall of the vertical groove 7, and a telescopic rod 14 is arranged inside the movable groove 13, and a connecting plate 15 is arranged on the telescopic rod 14 away from the side wall of the movable groove 13.

[0030] The inside of the vertical groove 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com