Dust remover filter bag packing machine

A dust collector and filter bag technology, which is applied in the field of dust collector filter bag balers, can solve the problems of low work efficiency, poor packing compactness, and high labor intensity of the staff, and achieves small space occupation, reduced labor intensity, and easy packing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples.

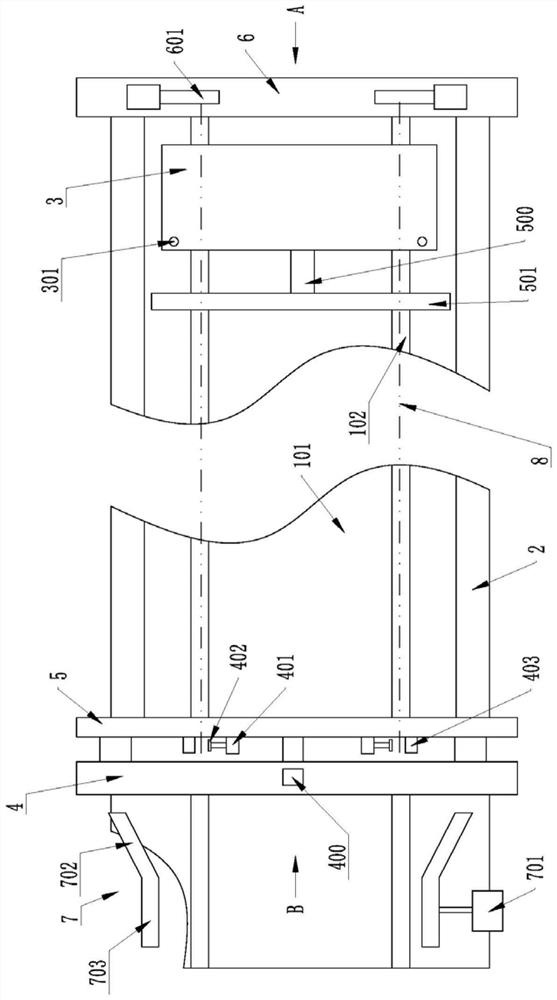

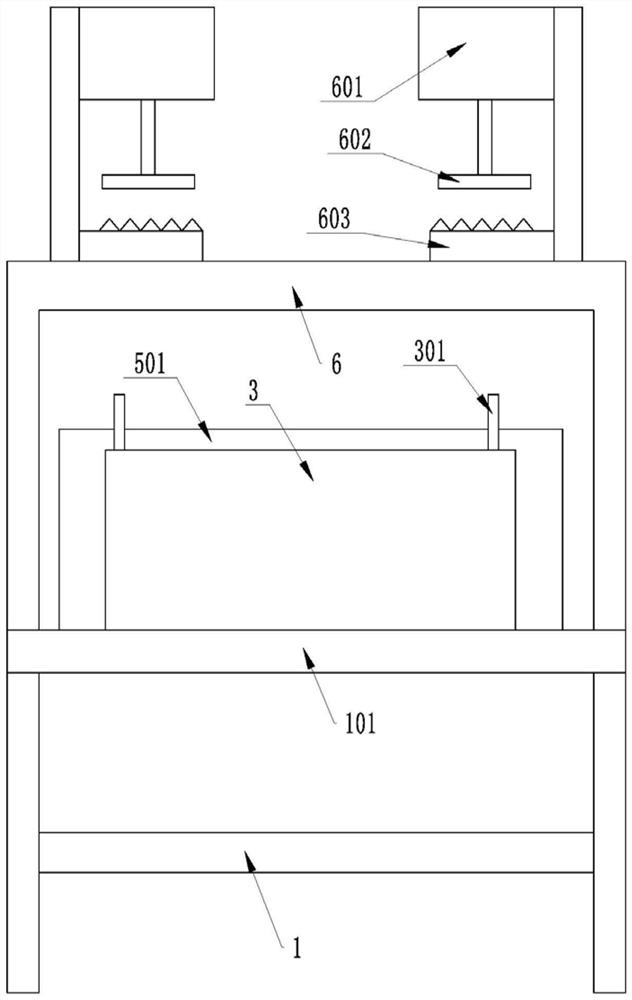

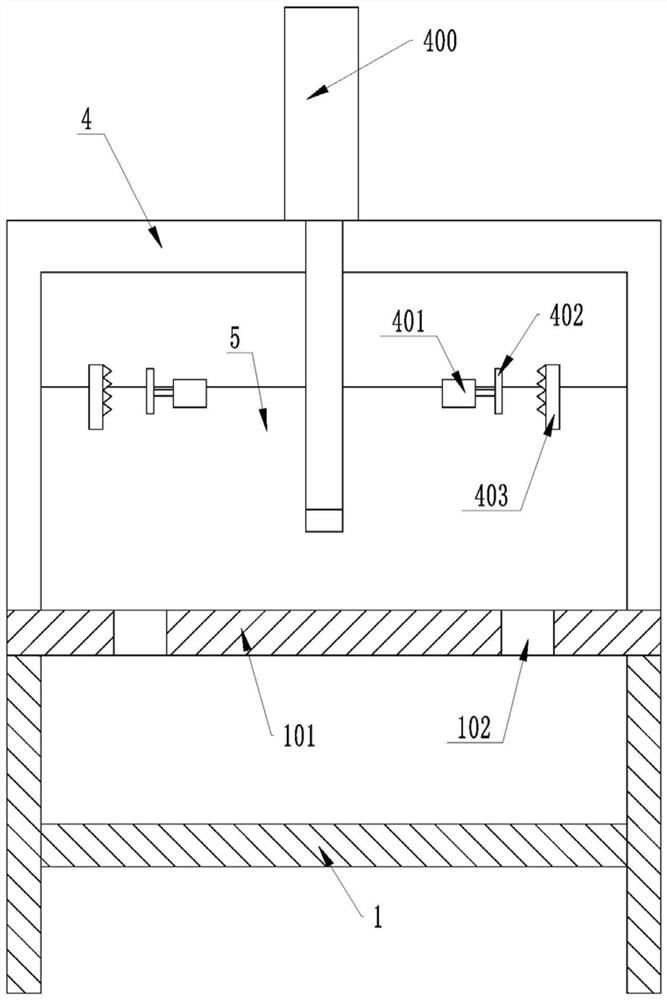

[0035] Such as Figure 1 to Figure 3 Commonly shown, a filter bag packing machine for a dust collector includes a frame 1 provided with a workbench 101, and both sides of the workbench 101 are provided with baffles 2, and are located on the workbench 101 between the two baffles 2. An extruding seat 3 driven by a power unit (not shown in the figure) is provided, and a first door frame 4 is arranged on the frame 1 at the end of the baffle plate 2, and a first door frame 4 is vertically moved on the first door frame 4. The gate 5 driven by the linear drive element 400 is provided with a guide and bag support mechanism extending to the top of the workbench 101 on the frame 1 located at the downstream of the gate 5; Two gantry frames 6, a tying rope fixing mechanism for clamping and fixing the tying rope 8 is arranged between the second gantry 6 and the shutter 5. As a preference, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com