Wing sleeve for laminar flow control technology flight test

A flight test and flow control technology, applied in the field of aerospace, can solve the problems of long development cycle and high cost, and achieve the effect of low cost, ensuring safety and maintaining aerodynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

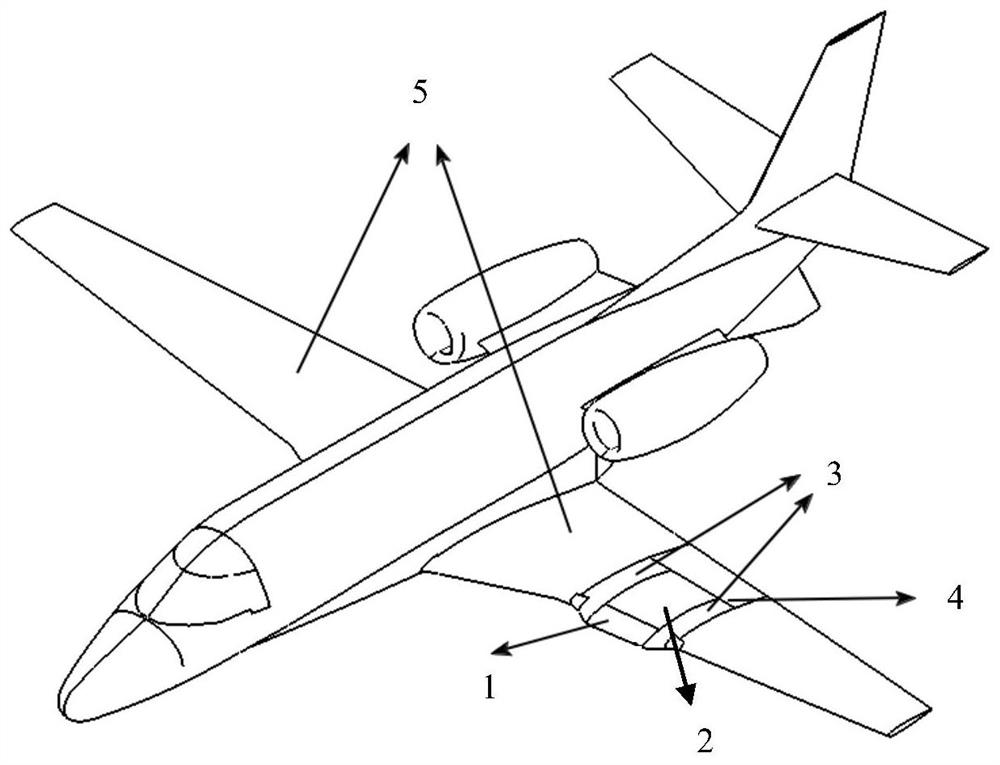

[0027] EXAMPLE 1. A wing sleeve for laminar flow control technology flight test, such as figure 1 As shown, including the laminar flow control wing, the laminar flow control wing set is provided with a replaceable front edge section 1, the test section 2, and the two transition segments 3, which can be replaced with the front edge section 1 and the test section 2 constitute a wing set effective test area. However, the replaceable front edge section 1 has the same exhibition length as the test section 2, which can be replaced with a leading edge section 1 using a smooth non-suction hole front edge section or a porous suction wall panel front edge section, and a smooth non-suction hole front edge section. Used to carry out the natural laminar flight test, the front edge section of the porous suction wall is used to perform a mixed layer flow control flight test, which can be replaced by flexible adjustment according to the purpose of the flight test, so that the wing is suitable for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap