Concrete detection sampling device for engineering supervision

A sampling device and concrete technology, which is applied to the sampling device and other directions, can solve the problems of easy collision, inconvenient to carry the sampling device, and affecting the sampling work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

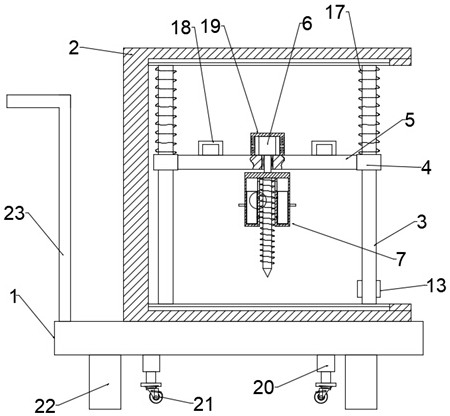

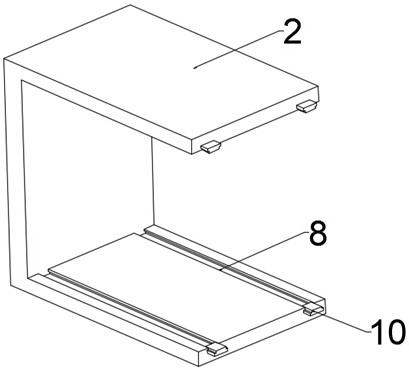

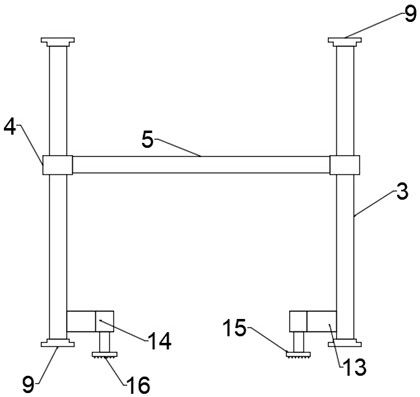

[0024] combine Figure 1-5 , a sampling device for engineering supervision concrete detection, including a base 1, the upper end of the base 1 is fixed with a 匚-shaped protective frame 2, and the upper and lower ends of the 匚-shaped protective frame 2 are provided with two convex chutes 8. The convex chute 8 is slidably connected with a convex sliding seat 9, and four connecting rods 3 are fixed between the convex sliding seats 9, and the four connecting rods 3 pass through the sliding cylinder 4 A mounting plate 5 is slidably connected, and a spring 17 sleeved on the outside of the connecting rod 3 is arranged between the sliding cylinder 4 and the convex sliding seat 9 at the upper end. A motor 6 is installed in the middle of the upper end of the mounting plate 5, Both sides of the motor 6 are provided with handrail handles 18, the output end of the motor 6 is connected with a sampling mechanism 7 through a rotating shaft, the rotating shaft is arranged through the mounting ...

Embodiment 2

[0030] combine figure 1 , a sampling device for engineering supervision concrete detection, this embodiment further limits the present invention on the basis of embodiment 1.

[0031] The lower end of the base 1 is equipped with a plurality of support columns 22 and a second electric push rod 20, the movable ends of the second electric push rod 20 are equipped with universal wheels 21, and the upper end of the base 1 is fixed with a hand push rod twenty three.

[0032] Specifically, the universal wheel 21 is adjusted to the bottom of the support column 22 through the second electric push rod 20 and is in contact with the ground, and the movement of the device is realized through the cooperation of the hand push rod 23 with the universal wheel 21. The universal wheel 21 is recovered above the support column 22 through the second electric push rod 20 , and the support column 22 provides stability support for the sampling process.

[0033]Working principle: the universal wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com