Parallel robot with six built-in rods and six degrees of freedom

A degree of freedom, built-in rod technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of affecting the load weight and insufficient supporting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

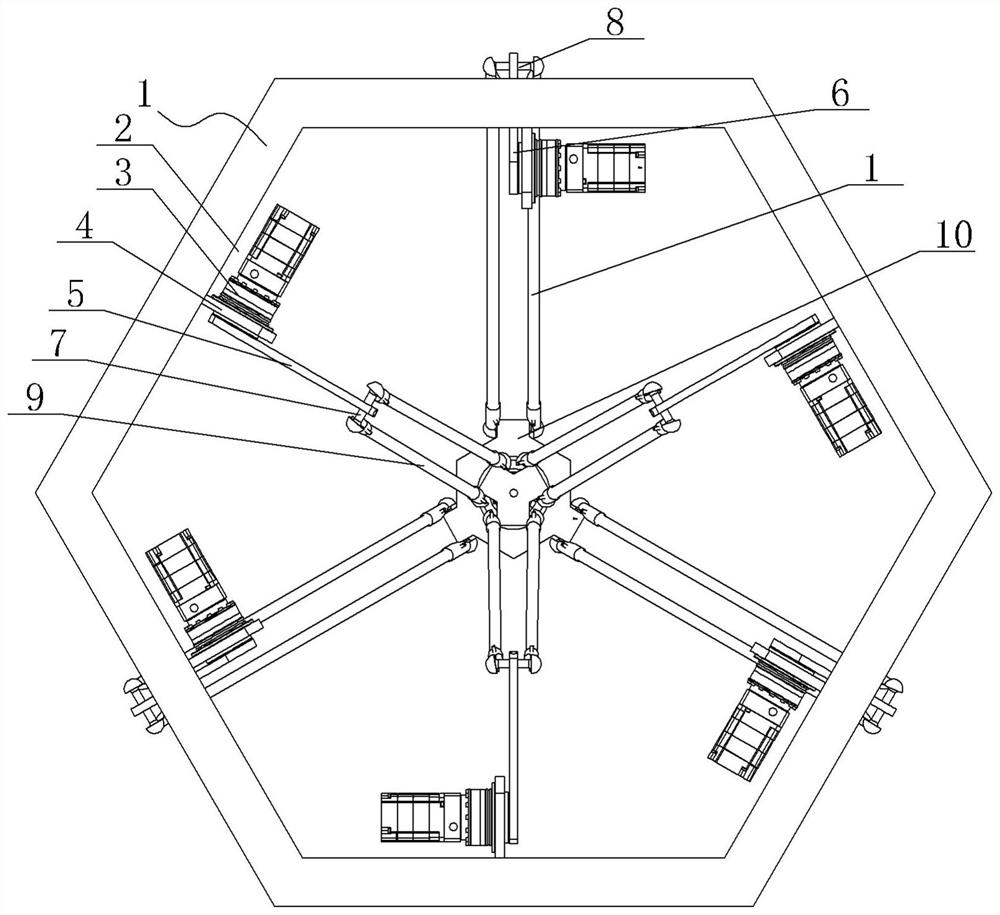

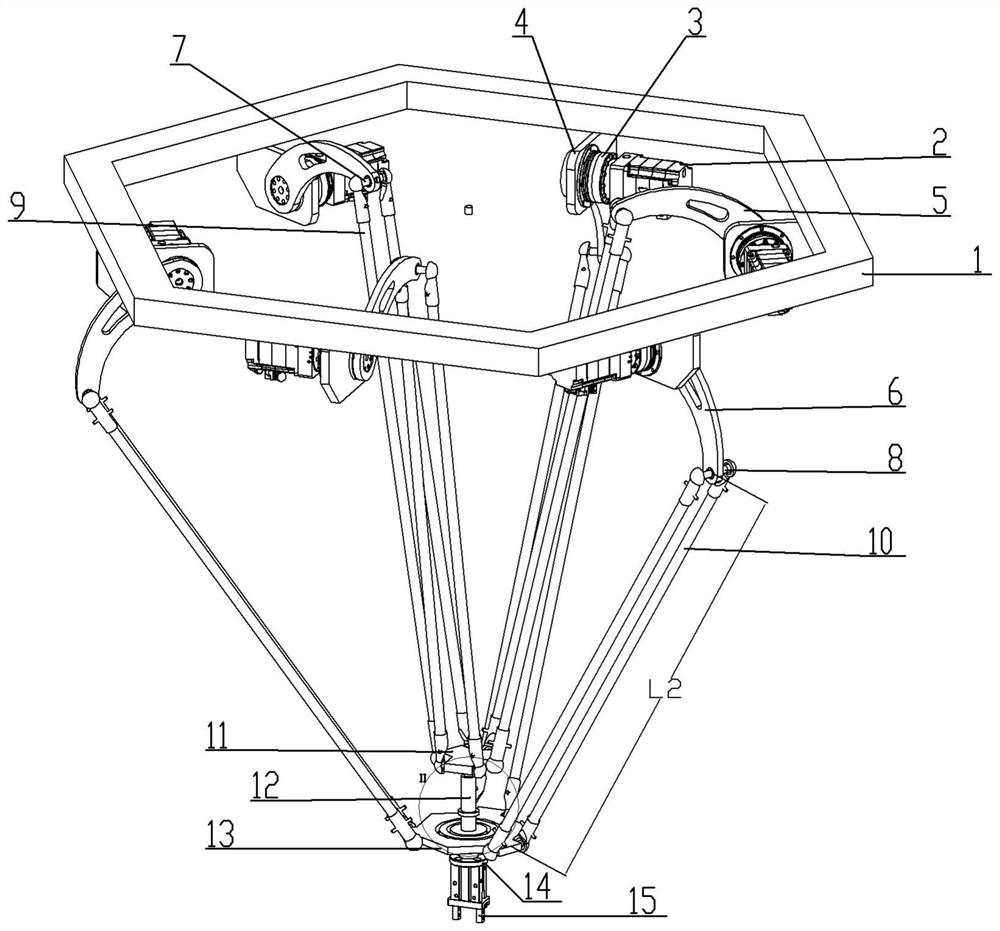

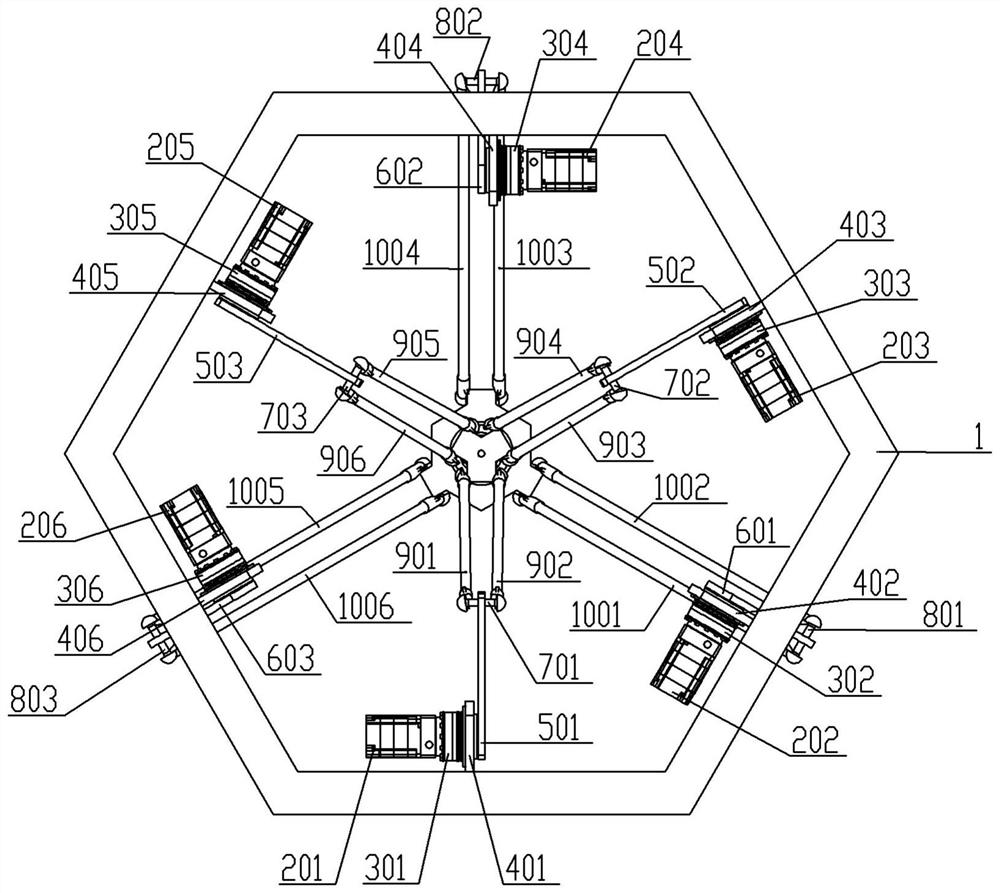

[0031] Six degrees of freedom parallel robot with six built-in rods, see Figure 1-Figure 5 : It includes a suspension frame 1, six groups of servo systems, six groups of transmission rod assemblies, an upper linkage plate 11, and a lower linkage plate 13;

[0032] The suspension frame 1 is specifically a regular hexagonal suspension frame, which is used for the hardware support of the overall structure, and a group of servo systems are respectively fixed in the central area of each side of the regular hexagonal suspension frame;

[0033] Each set of servo systems is used to transmit power, and the output end of the servo system is connected to the power transmission arm of the transmission rod assembly of the corresponding set;

[0034] The six sets of transmission rod assemblies include three sets of inner upper transmission rod assemblies 100 and three sets of outer lower transmission rod assemblies 200. The inner upper transmission rod assembly 100 includes the first pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com