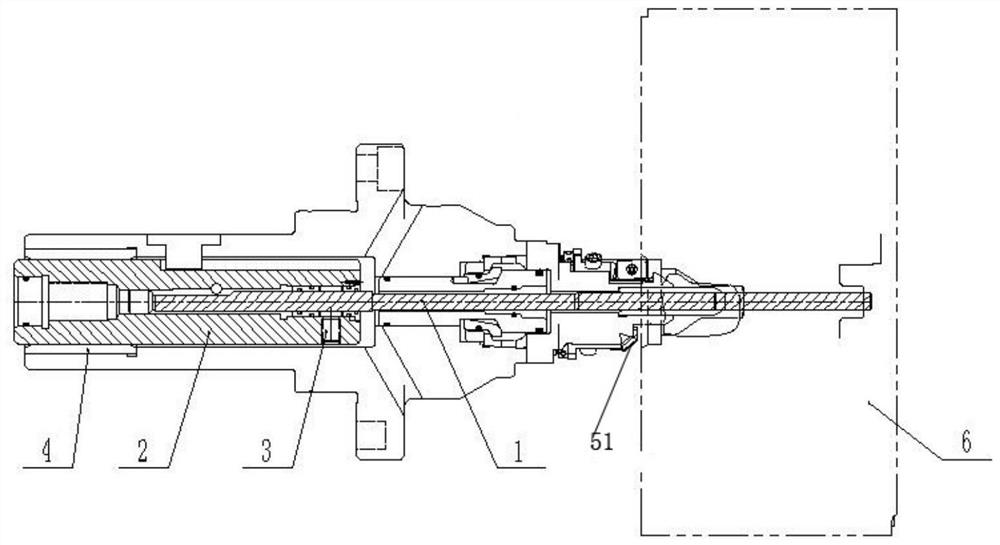

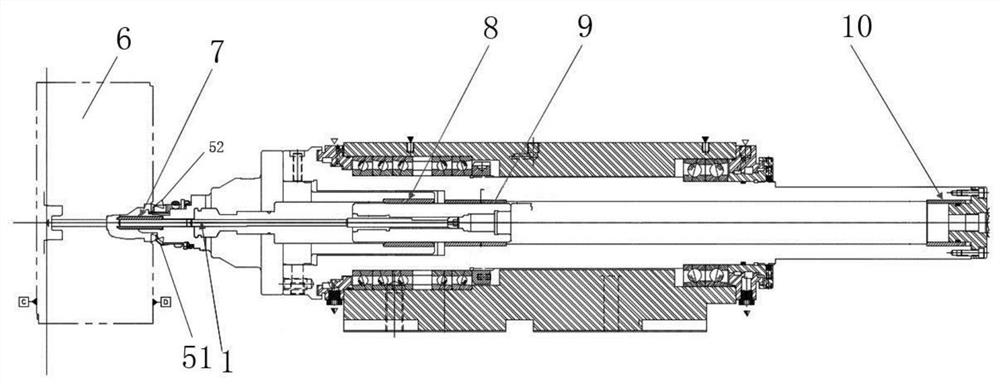

A hydraulic boring head for machining conduits of engine cylinder head seat rings

A technology for engine cylinder heads and seat rings, which is applied in boring heads, metal processing equipment, manufacturing tools, etc., and can solve problems such as long tool and tool clamping parts, non-uniform guidelines for tool travel in conduit holes, and unstable tool processing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

[0036] Attached below Figure 1-3 The existing processing methods of the seat ring hole and the guide hole will be described.

[0037] As described in the background technology, the conduit hole or the seat ring hole of the engine cylinder head is irregular and the roundness does not meet the standard. The reasons are as follows: 1) The cutter is fixed by a lateral pressure screw, The screw makes the tool deviate from the center of rotation of the mandrel, resulting in a large tool jump; 2) There are many constraining surfaces for the conduit hole cutter during the feeding process, and the coaxiality problem between multiple constraint surfaces will make the travel benchmark of the conduit hole cutter Not uniform; 3) The clamping part between the tool and the tool is too long, which makes the tool extremely unstable during processing. The specific reasons for the above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com