Movable high-temperature snowmaker

A mobile snowmaking technology, applied in the manufacture of ice, lighting and heating equipment, household appliances, etc., can solve the problems of low thermal conductivity of carbon steel and stainless steel, difficult chrome plating process, heavy cleaning workload, etc., to avoid chrome plating process , product consistency, product quality improvement, and the effect of reducing production workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

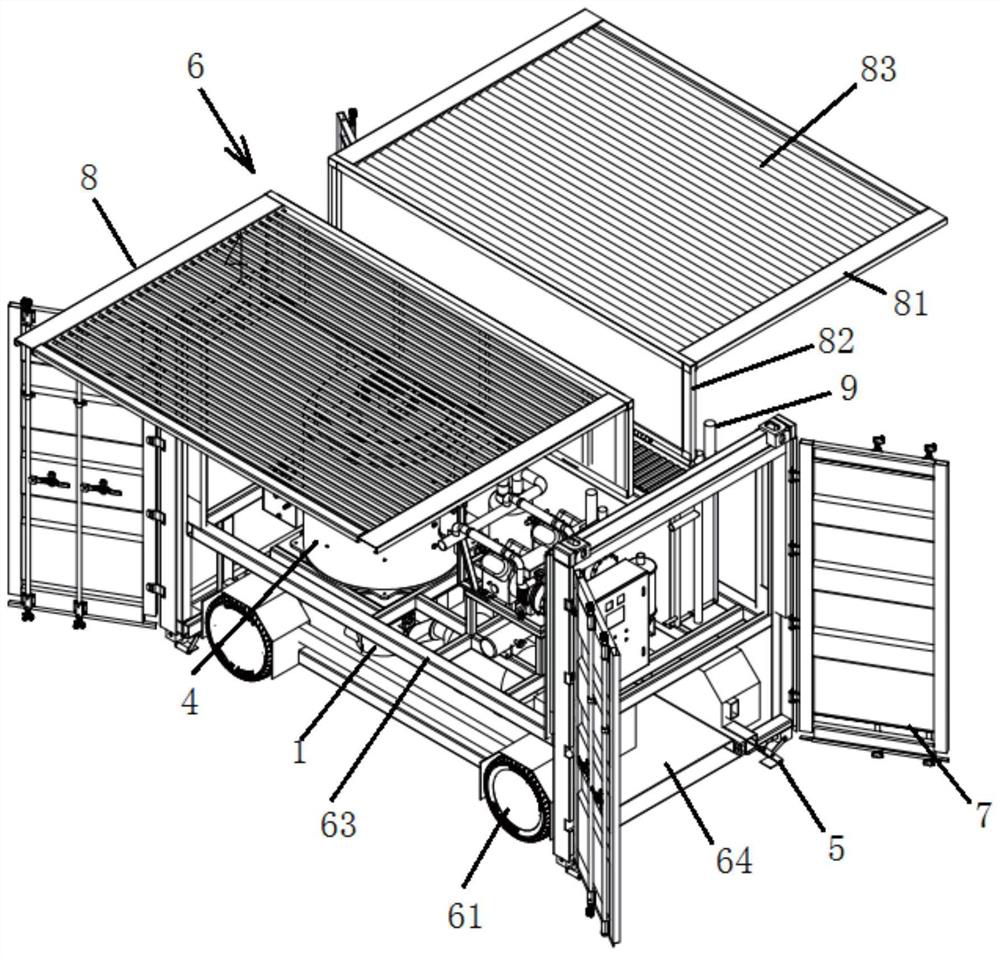

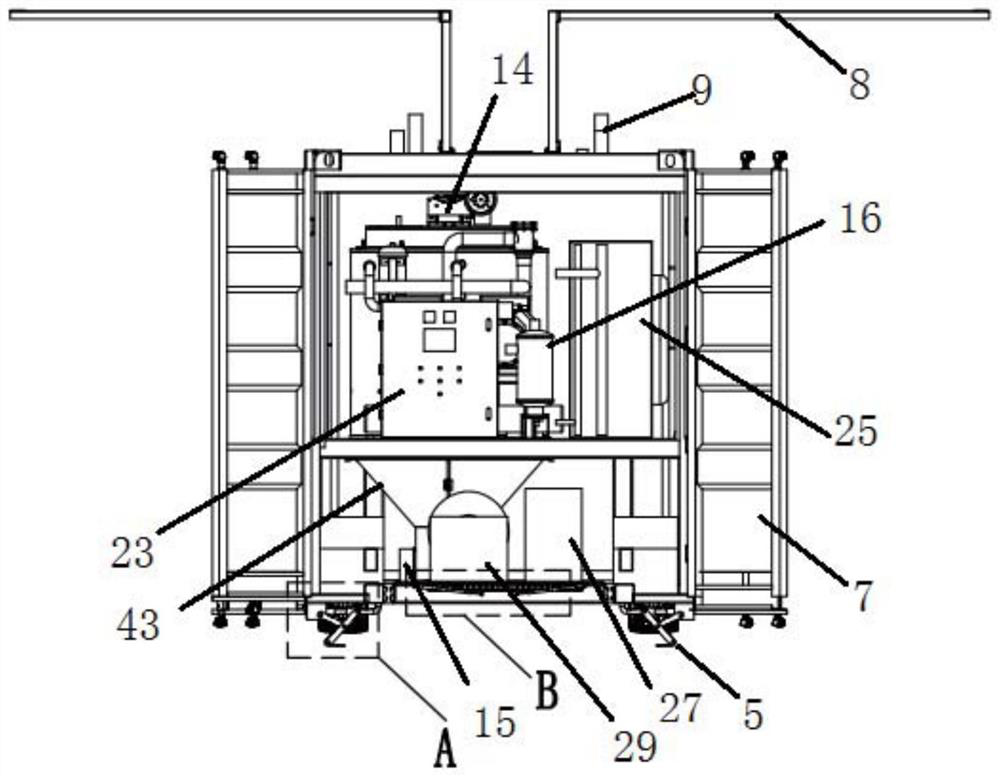

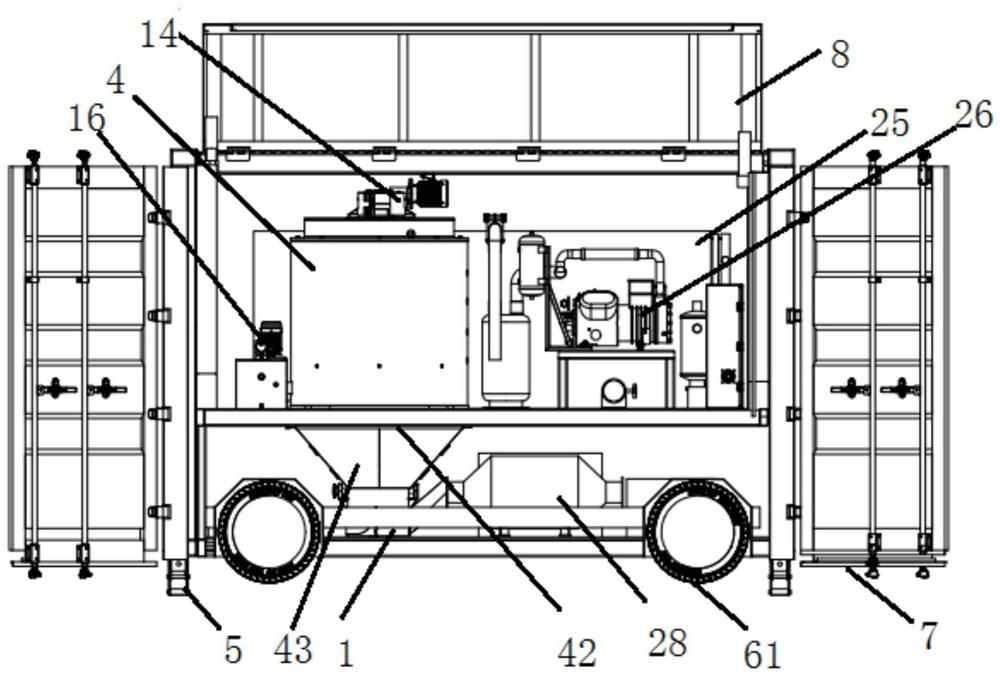

[0046] Such as Figure 1-14 As shown, the embodiment of the present invention discloses a mobile high-temperature snowmaking machine, which includes a car body 6, an ice maker and a crushing snowmaking machine. Of course, an electric control cabinet 23 is also provided inside to drive the movement of various components. , below the car body 6, wheels 61 and car body support seat 5 are installed. The wheels 61 ensure that the car body 6 has the ability to move flexibly. Whole car body 6 is fixed. The car body 6 includes an upper bracket 63 and a lower bracket 64. The ice maker is installed on the upper bracket 63, and the crushing snow machine is installed on the lower bracket 64. The bottom of the ice bucket 4 of the ice maker is provided with a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com