Bridge pier strength monitoring equipment based on bridge safety detection

A technology for monitoring equipment and safety, applied in bridge construction, bridges, bridge parts, etc., can solve problems such as short battery life, affecting equipment fixation, and increasing battery consumption, so as to improve battery life, improve installation efficiency, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

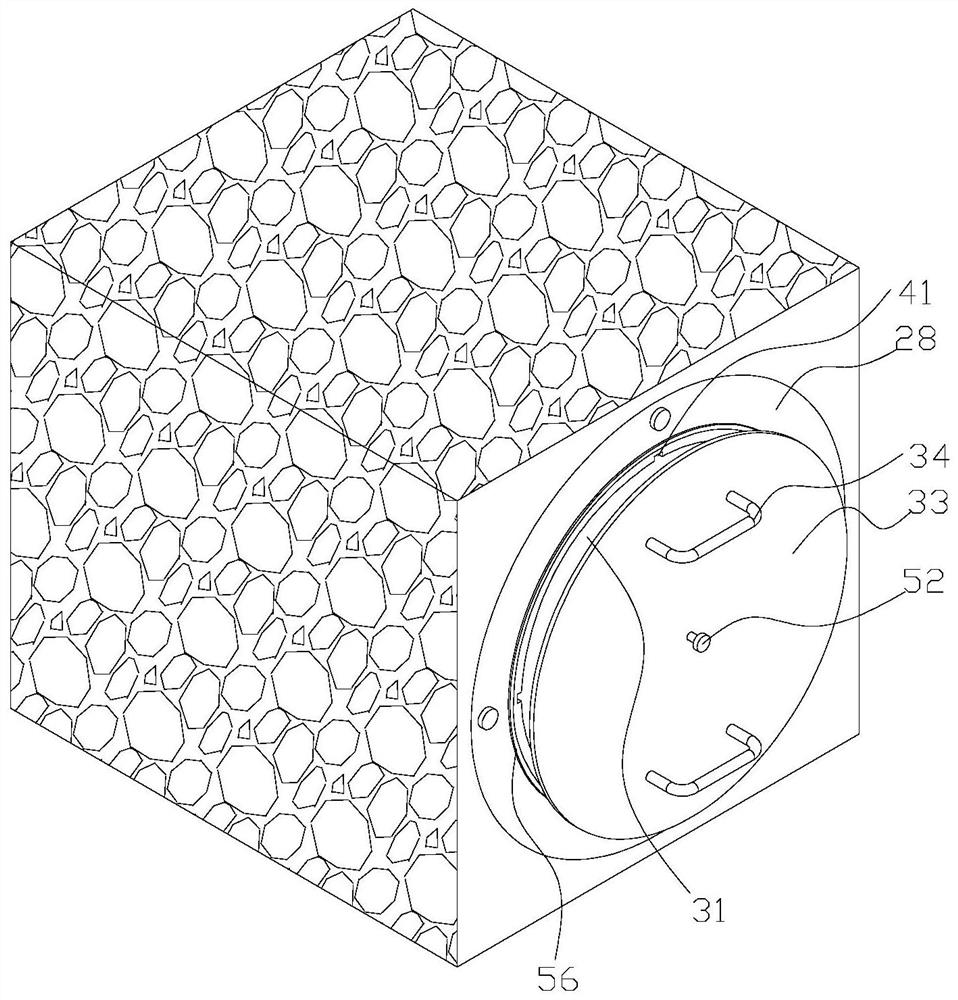

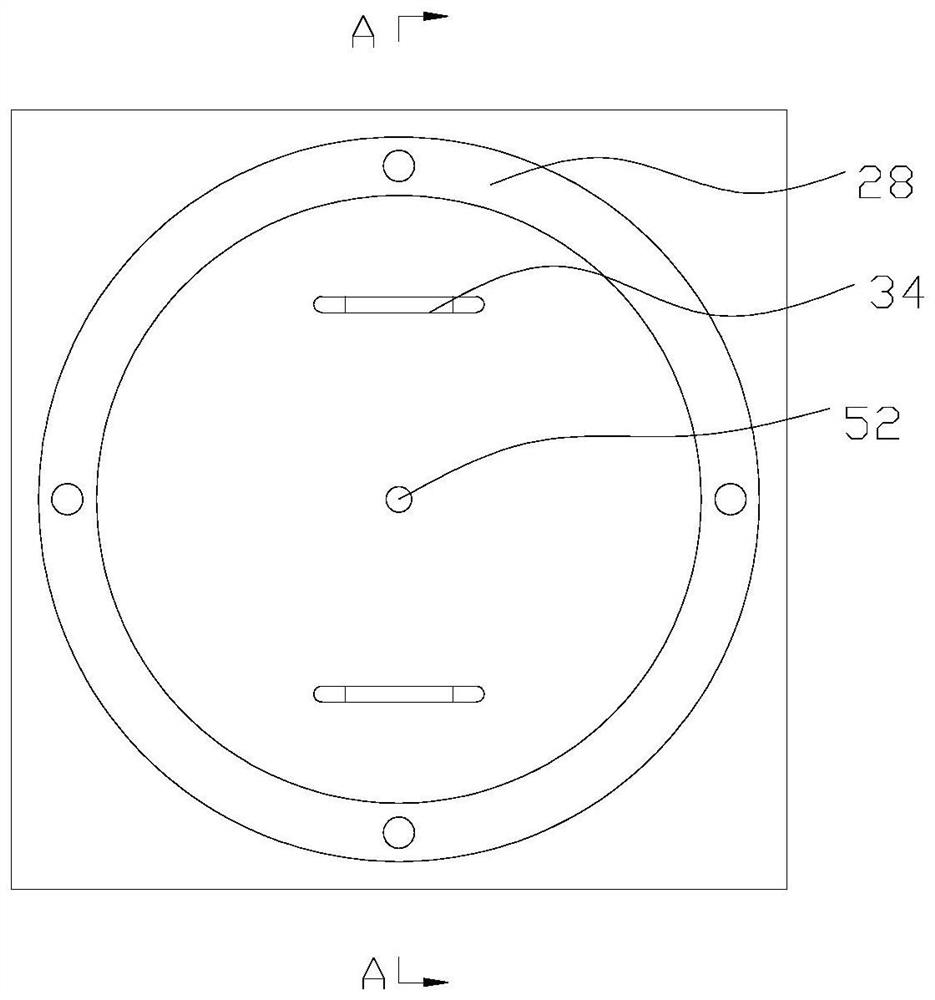

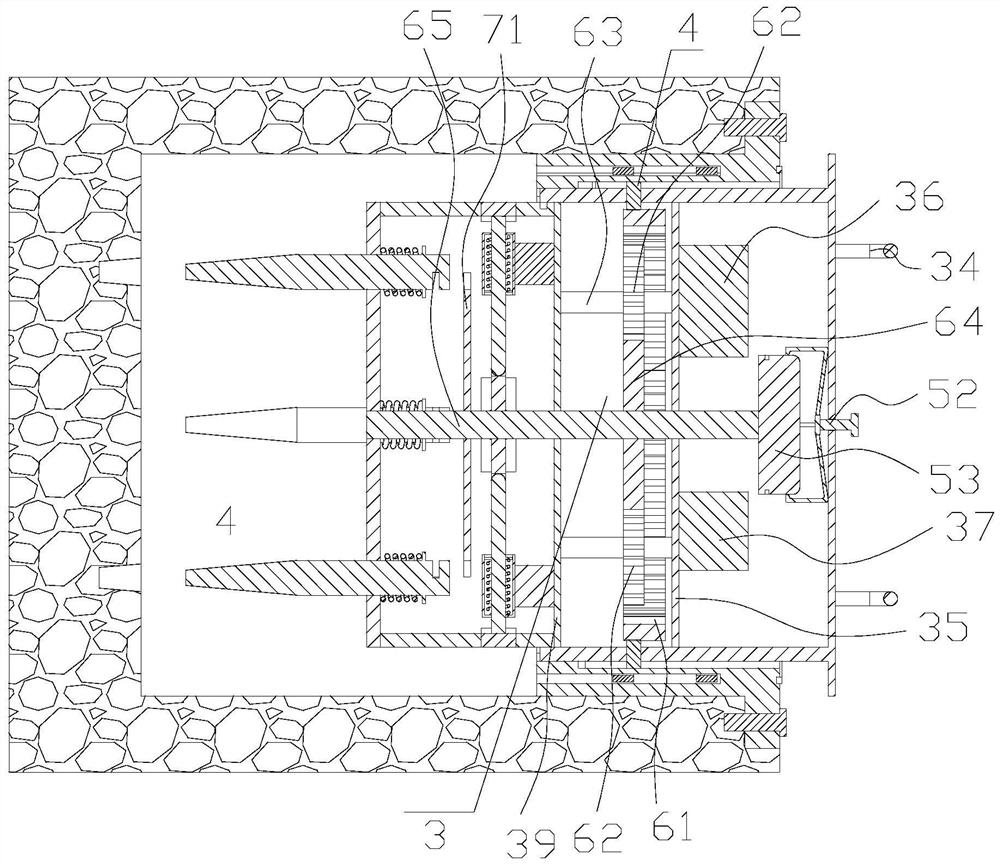

[0028] Such as Figure 1-15As shown, a bridge pier strength monitoring device based on bridge safety detection includes an installation hole 11 and a positioning hole 12; the installation hole 11 is opened on the bridge pier; the positioning hole 12 is opened on the left side of the installation hole 11; Part 2 and monitoring part 3; the embedded part 2 is fixed in the installation hole 11; the monitoring part 3 is arranged inside the embedded part 2; the monitoring part 3 includes an outer cylinder 31, an inner cylinder 32, and a guide assembly 4. Cover plate 33, anti-loosening piece 5, handle 34, first partition 35, battery 36, strength analyzer 37, booster assembly 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com