A control method for anti-rollover of counterbalanced forklift

A control method and anti-rollover technology, applied in lifting equipment safety devices, hoisting devices, etc., can solve the problems of hidden dangers of operators and goods, large lateral acceleration, easy instability of forklifts, etc., and achieve low risk of rollover , reduce the roll angle and yaw rate, the effect of accurate and real-time judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

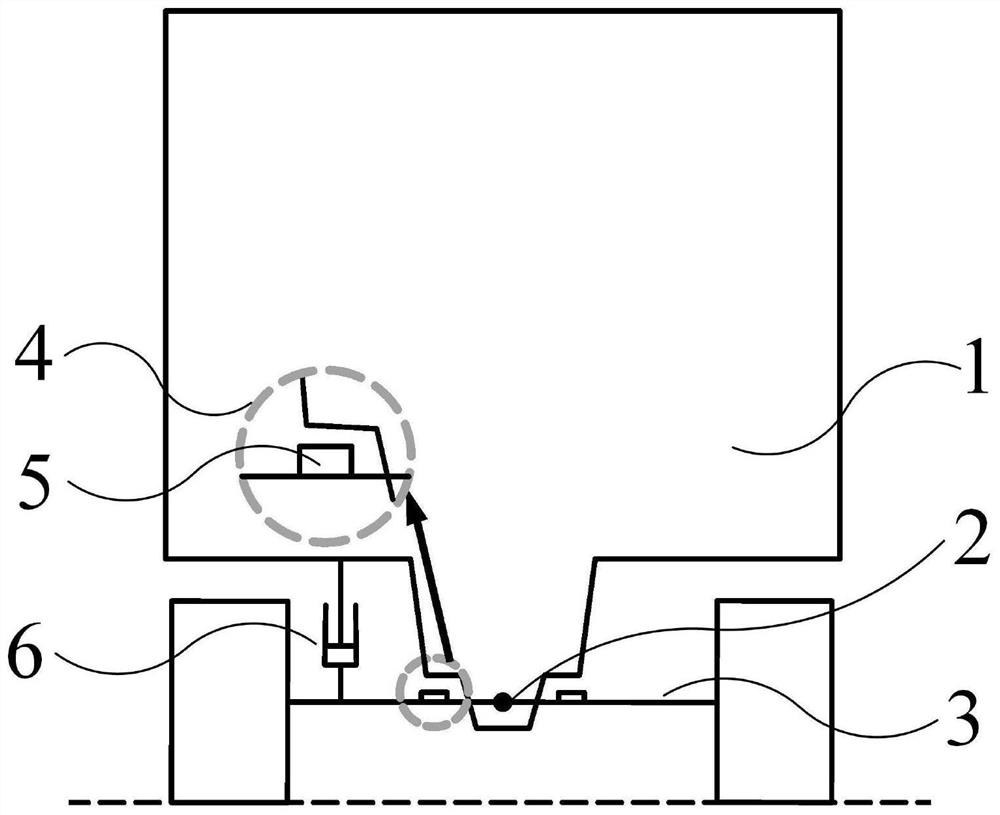

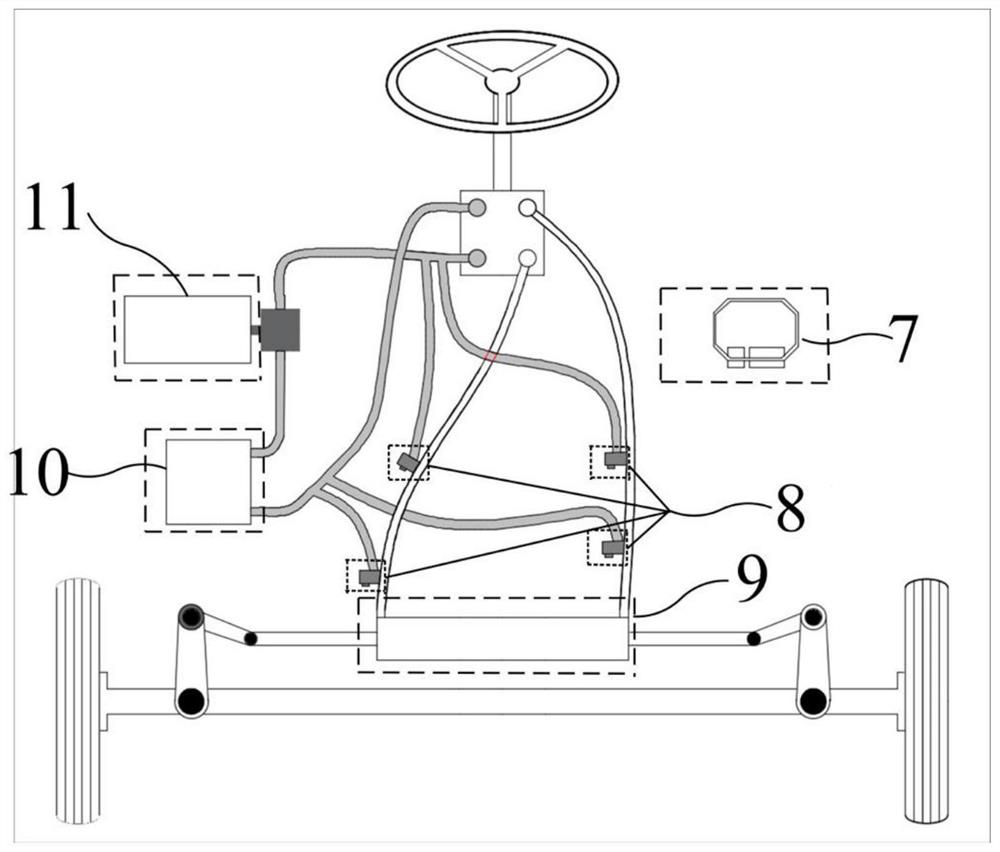

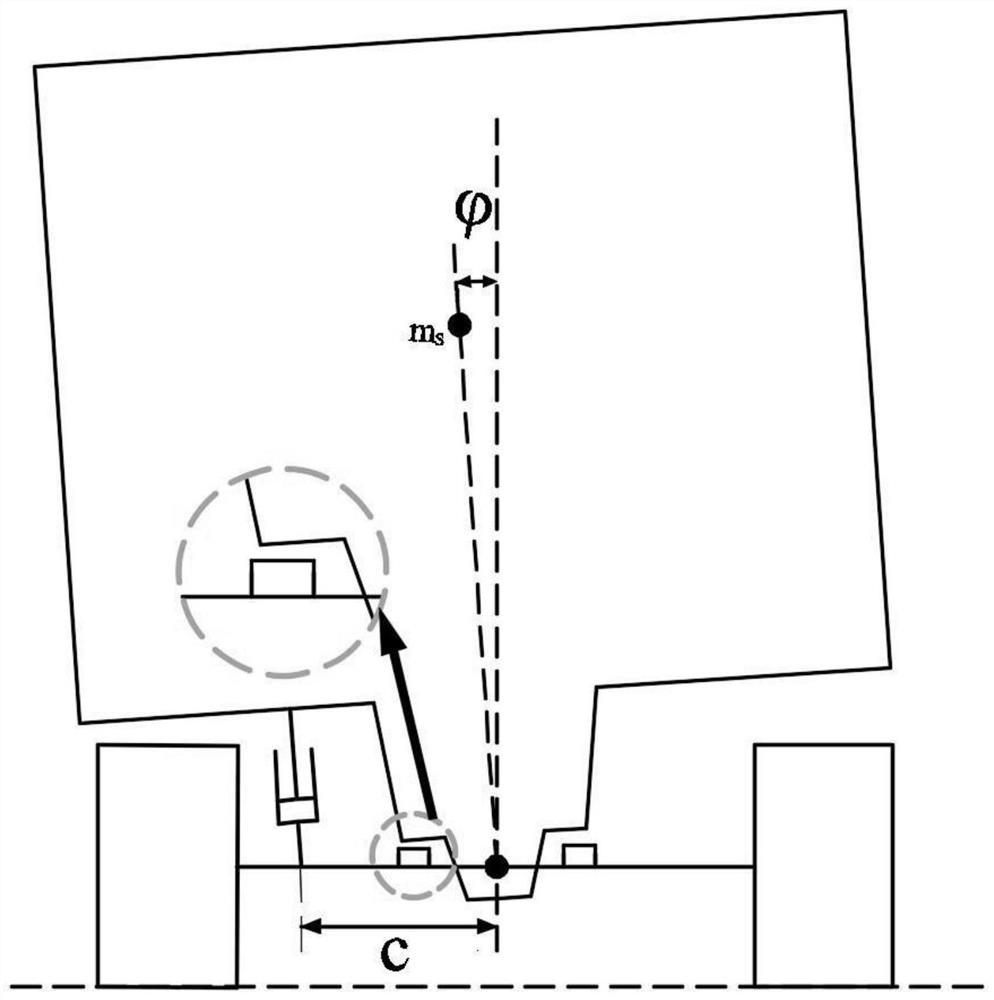

[0110] Embodiment: the anti-rollover control method of forklift trucks of the present invention is applied to a certain type of 3-ton counterbalanced forklift. s =4300kg, moment of inertia I of the whole vehicle around the Z axis z =6129kg·m 2 , the moment of inertia of the frame around the X axis I x =3100kg·m 2 , height h of body center of mass s =0.75m, the height of the center of mass of the rear axle is equal to the height of the hinge point of the rear axle h r = h u0 =0.265m, the distance between the front axle and the center of mass a=1m, the distance between the rear axle and the center of mass b=0.7m, the wheelbase B=1m, the maximum swing angle of the body relative to the rear axle The locked state of the hydraulic support oil cylinder refers to the PWM duty cycle signal with the control signal of the solenoid valve of the oil cylinder being 0%, the semi-free state refers to the PWM duty cycle signal with the control signal of the solenoid valve of the oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com