Automatic turnover double-sided gluing production line for doors and windows as well as processing method thereof

An automatic flipping and production line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unstable glue quality, low degree of automation, and high labor intensity, so as to save manpower, reduce labor intensity, facilitate processing and The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

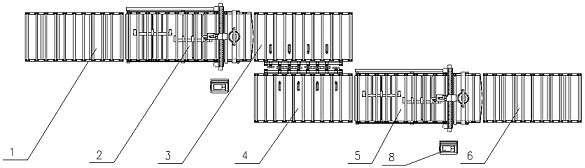

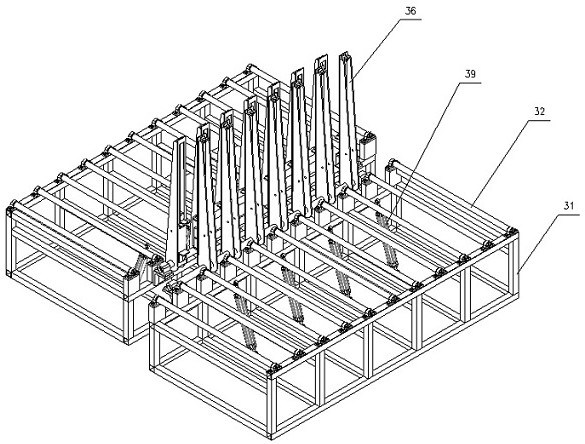

[0068] see Figure 1 to Figure 14 , a door and window automatic flipping double-sided gluing production line, including a feeding conveying device 1, a first automatic gluing machine 2, a turning machine, a second automatic gluing machine 5, a discharging conveying device 6, a pneumatic system and an electrical control system The overturning machine includes a left overturning device 3 and a right overturning device 4, the feeding conveying device 1, the first automatic gluing machine 2, and the left overturning device 3 are arranged in the first column in sequence according to the direction of travel of the processed doors and windows 7, and the right overturning The device 4, the second automatic gluing machine 5, and the discharge conveying device 6 are arranged in the second column according to the traveling direction of the door and window 7 to be processed, the first column and the second column are parallel to each other, and the left turning device 3 and the right The ...

Embodiment 2

[0075] A method for processing doors and windows by using the automatic double-sided gluing production line for doors and windows, comprising the following steps:

[0076] 1. Put the assembled door and window 7 on the DC brushless electric roller 32 of the feeding conveying device 1, and the control system starts the DC brushless electric roller 32 to rotate, and conveys the door and window 7 to the first automatic gluer 2;

[0077] 2. After the sensor on the first automatic gluing machine 2 detects the door and window 7, the conveying roller on the gluing machine stops rotating, the rodless cylinder 37 drives the pressing device to press the door and window 7, and the edge patrol mechanism on the head of the gluing machine Automatically patrol the edge, and then glue the inside of the door and window 7 for a week. After the glue is glued, the machine head rises; the conveying rollers convey the door and window 7 to the left turning device 3;

[0078] 3. The DC brushless elect...

Embodiment 3

[0086] A door and window automatic flip double-sided glue production line, the door and window conveying device includes a reducer with a motor installed at one end of the flip frame 31 / feed frame / discharge frame, the output shaft of the reducer is installed with a driving sprocket, At least 3 conveying rollers are rotatably connected to the upper plane of the turning frame 31 / feeding frame / discharging frame, and one end of the conveying roller is equipped with a double-row driven sprocket, and the chain connects the driving sprocket to the conveying roller close to the reducer. The driven sprockets are connected, and the driven sprockets on other conveying rollers are connected in turn by chains. All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com