Automatic scraping device for bamboo joint burrs

A scraping device and burr technology, applied in the field of plants, can solve the problems of easy scratching of bamboo and wood, time-consuming and laborious, rough bamboo joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

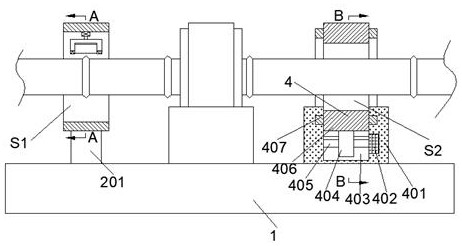

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as Figure 1-8 As shown, an automatic scraping device for bamboo burrs includes a base 1, and a scraping mechanism S1 for scraping bamboo burrs is fixed on the upper surface of the base 1. When working, the scraping mechanism S1 first blocks and stops the bamboo through the bamboo joints, and then performs the scraping operation of bamboo burrs. After the burrs are scraped off, the scraping mechanism S1 can no longer block the bamboo through the bamboo joints. , and then bamboo and wood will continue to feed.

[0024] One side of the scraping mechanism S1 is provided with two bamboo rotating assemblies 4 fixed on the upper surface of the base 1 for rotating bamboo. The bamboo and wood rotating assembly 4 is used to make the bamboo and wood rotate, and then cooperate with the upper scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com