Hoisting equipment for material carrying

A technology for hoisting equipment and materials, used in transportation and packaging, safety devices, load hoisting components, etc., can solve problems such as material swaying, difficulty in ensuring hoisting safety during hoisting, roller damage, etc., to facilitate maintenance, maintenance and replacement. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

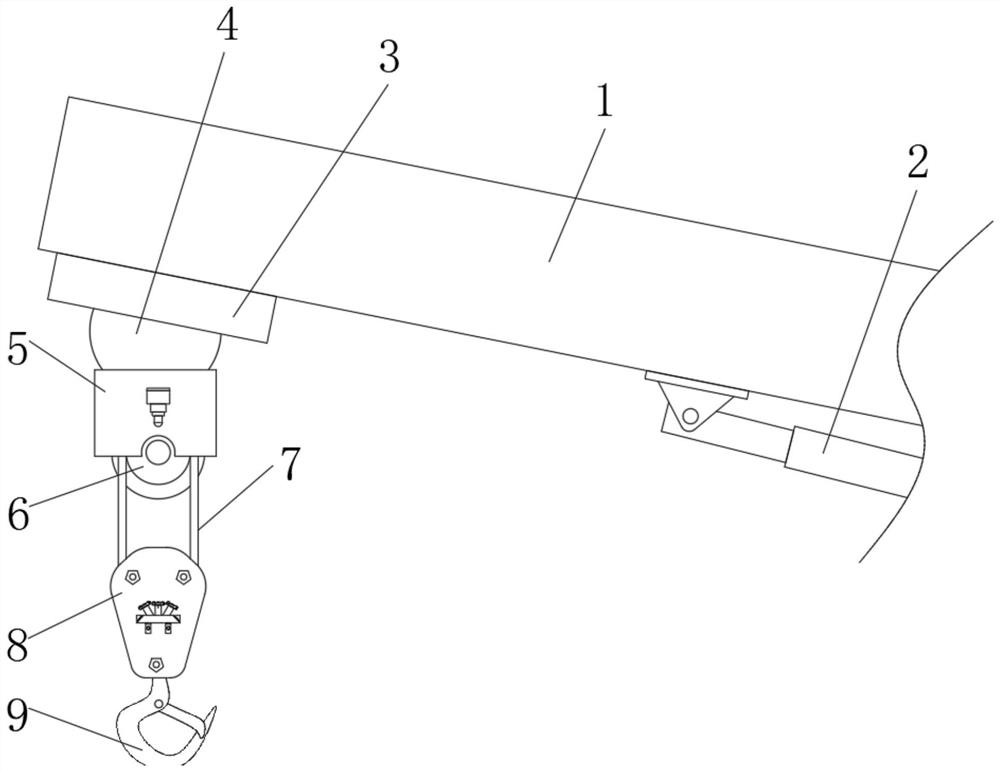

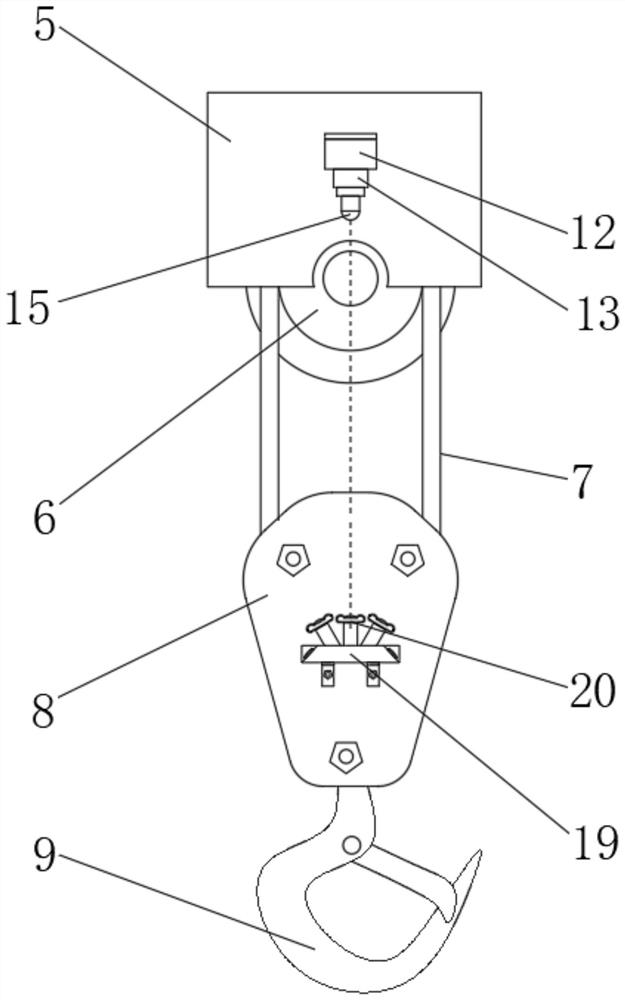

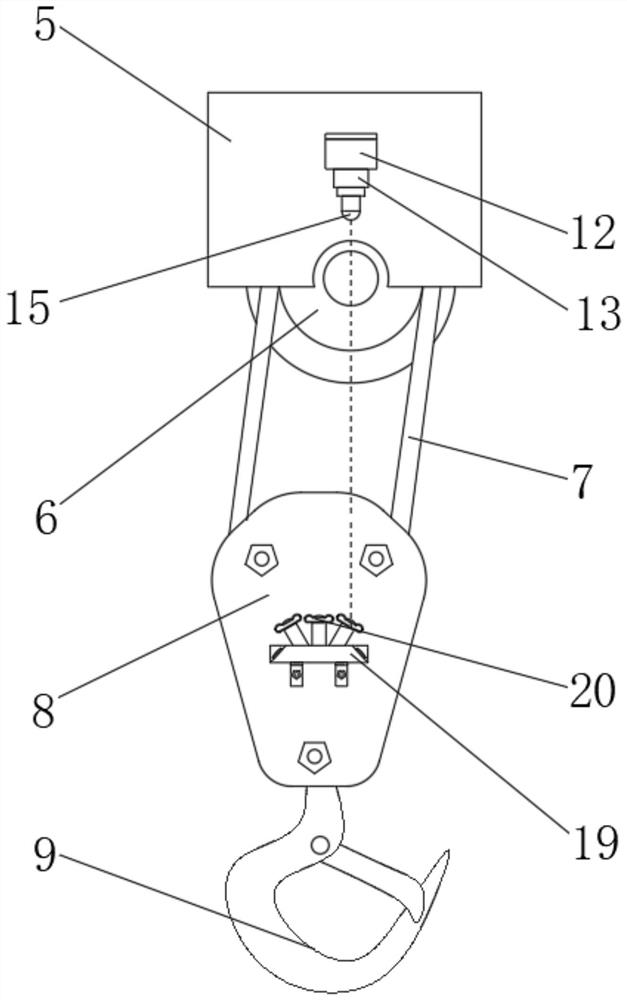

[0040] see Figure 1-7 , a hoisting device for material handling, comprising a hoisting arm 1, a hydraulic rod 2 is fixedly installed at the lower end of the middle part of the hoisting arm 1, a stabilizer 3 is fixedly installed at the lower left end of the hoisting arm 1, and the lower side of the stabilizer 3 The inner rotation is connected with a rotating shaft 4, and the lower side of the rotating shaft 4 is connected with a control winding frame 5, and the inner rotation of the control winding frame 5 is connected with a steel wire roller 6, and the outer surface of the steel wire roller 6 is connected with a steel wire 7. The bottom is connected with a hook mounting part 8, the lower side of the hook mounting part 8 is fixedly installed with a hook 9, the front end of the control winding frame 5 is fixedly mounted with a welding frame 10, and the rear upper end of the welding frame 10 is rotatably connected with a fastening cover A control terminal 12 is installed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com