Water treatment equipment

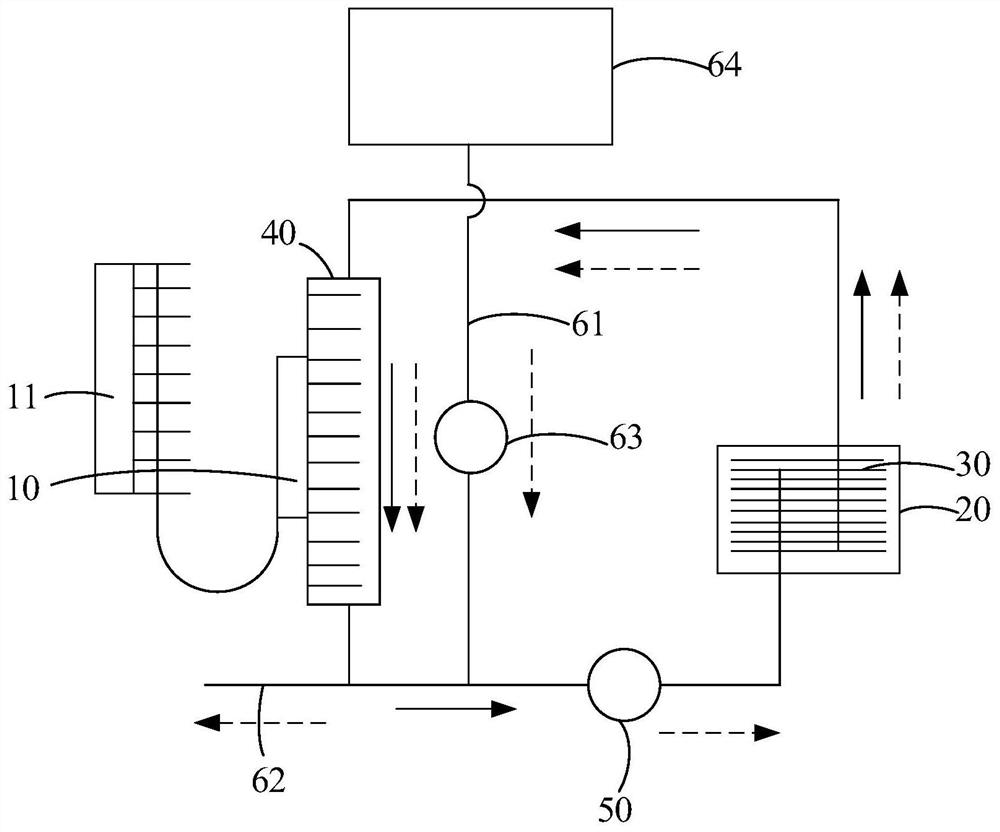

A water treatment equipment and water pump technology, applied in water/sewage treatment, thermal storage equipment, water/sludge/sewage treatment, etc., can solve the problems of not being able to produce cold water immediately, being large in size, and prone to failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0057] The cold water temperature in the energy storage loop is 3.1°C (referring to the energy storage loop when the water inlet solenoid valve 63 is closed), the inlet water temperature of the water inlet pipe 61 is 25°C, and the phase change heat exchanger 30 is a plate heat exchanger device, the heat exchange area of the phase change heat exchanger 30 is 0.17m 2 , the phase change temperature of the phase change material is 5°C, and the thermal conductivity is 0.2W / m.K. At this time, take 1L of water continuously, and the final water temperature in the cup is about 12.8°C; take another 250ml of water at an interval of 5 minutes, and you can get 3 cups of water below 10°C.

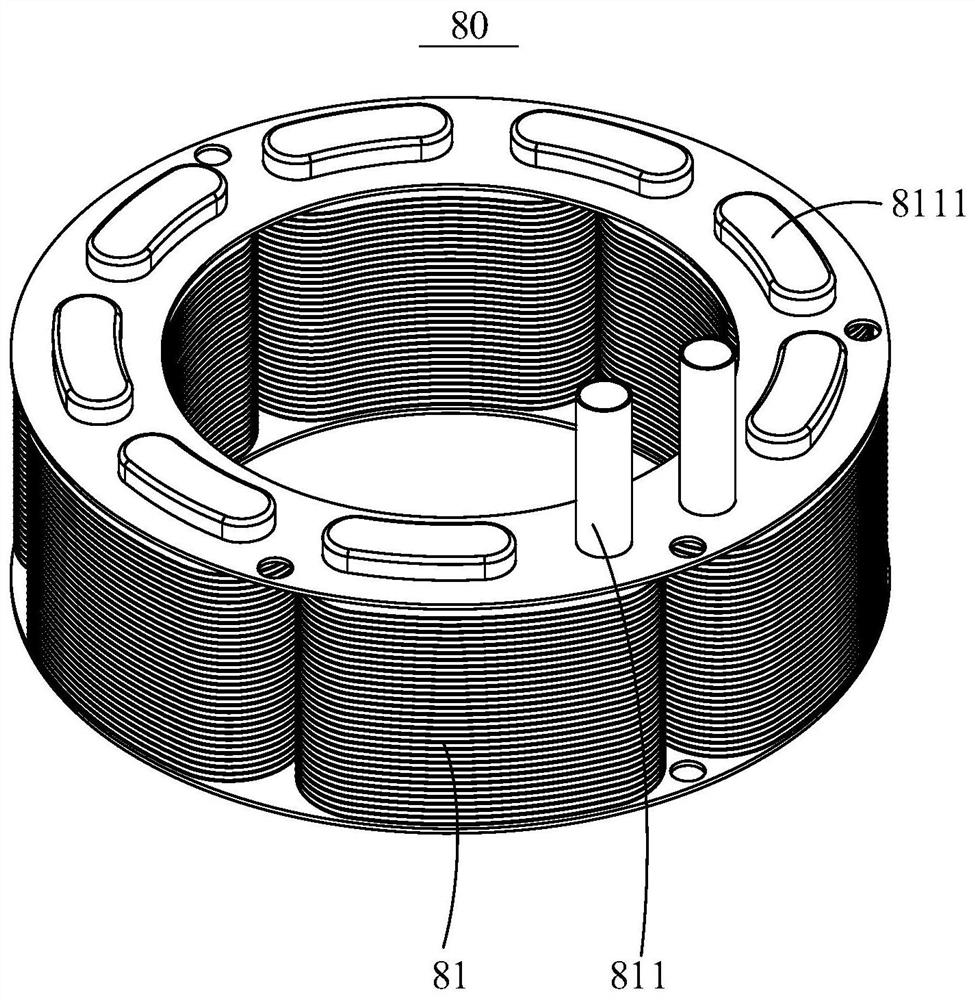

example 2

[0059] The cold water temperature in the energy storage loop is 3.1°C (referring to the energy storage loop when the water inlet solenoid valve 63 is closed), the inlet water temperature of the water inlet pipe 61 is 25°C, and the phase change heat exchanger 30 is a finned tube type Heat exchanger 80, the heat exchange area of phase change heat exchanger 30 is 0.17m 2 , the phase change temperature of the phase change material is 5°C, and the thermal conductivity is 0.6W / m.K. At this time, take 1L of water continuously, and the final water temperature in the cup is about 9.6°C; take another 250ml of water at an interval of 5 minutes, and you can get 5 cups of water below 10°C.

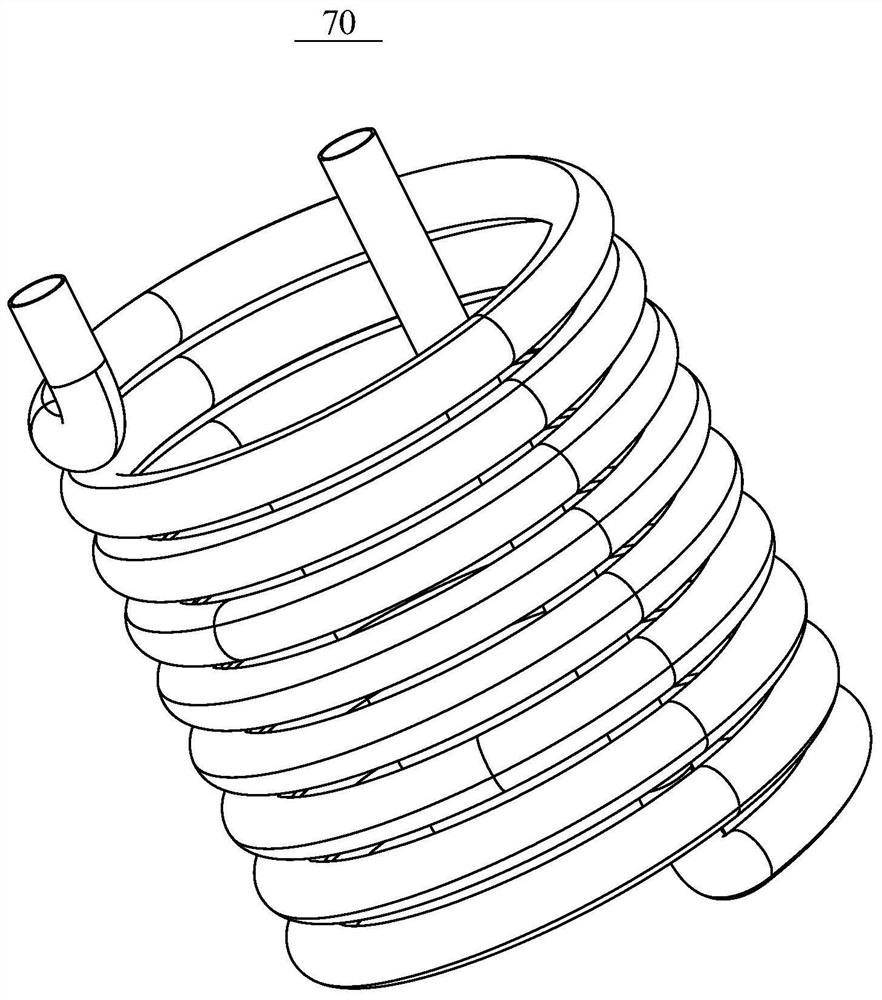

example 3

[0061] The cold water temperature in the energy storage loop is 3.1°C (referring to the energy storage loop when the water inlet solenoid valve 63 is closed), the inlet water temperature of the water inlet pipe 61 is 25°C, and the phase change heat exchanger 30 is a bare tube type Heat exchanger 70, the heat exchange area of phase change heat exchanger 30 is 0.078m 2 , the phase change temperature of the phase change material is 5°C, and the thermal conductivity is 1W / m.K. At this time, take 1L of water continuously, and the final water temperature in the cup is about 12.5°C; take another 250ml of water at an interval of 5 minutes, and you can get 3 cups of water below 10°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com