A kind of artificial bone repair material with osteogenic activity and mechanical support performance and its preparation method and application

A repair material and osteogenic activity technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve problems such as inability to flexibly control the composite ratio of inorganic active materials, limited composite ratio of inorganic active materials, and failure to meet the use requirements , to achieve the effects of regular surface structure, high degree of bonding and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

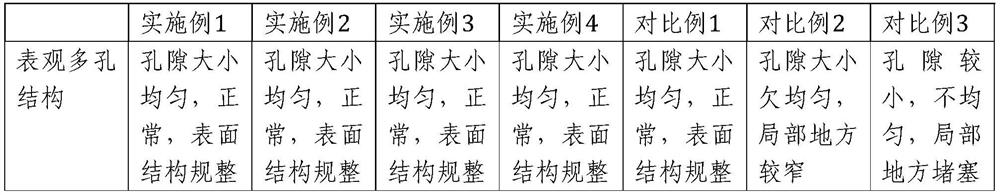

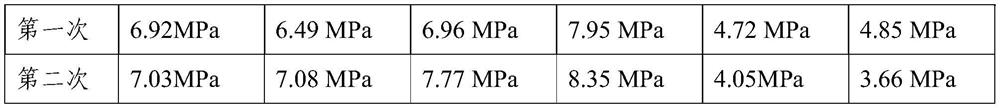

Examples

Embodiment 1

[0040] The present embodiment provides a method for preparing an artificial bone repair material, comprising the following steps:

[0041] (1) Take natural pine beef bone, prepare a long strip structure of 1cm*1cm*2cm, remove blood fat and bone marrow and other components and rinse fully, and then use hydrogen peroxide ultrasonically soaked for 90min to further remove fat components, soaked in absolute ethanol for 30min to further inactivate the virus components, and then further cleaned with surfactant in water and dried, to obtain natural biological bone scaffold material backup;

[0042] (2) According to the quality score, the SiO will be 2 45%,CaCO 3 25%,Na 2 CO 3 20%,P 2 O 5 5%,MgCO 3 5% well mixed, calcined at high temperature at 1200 °C, and kept at a stable temperature for 5h to form a stable molten state bioactive material;

[0043] (3) The natural biological bone scaffold material prepared in step (1) is fixed with a high-temperature resistant ceramic material, and its v...

Embodiment 2

[0048] The present embodiment provides a method for preparing an artificial bone repair material, comprising the following steps:

[0049](1) Take natural pine beef bone, prepare a long strip structure of 1cm*1cm*2cm, remove blood fat and bone marrow and other components and rinse fully, and then use hydrogen peroxide ultrasonically soaked for 90min to further remove fat components, soaked in absolute ethanol for 30min to further inactivate the virus components, and then further cleaned with surfactant in water and dried, to obtain natural biological bone scaffold material backup;

[0050] (2) According to the quality score, the SiO will be 2 45%,CaCO 3 25%,Na 2 CO 3 20%,P 2 O 5 5%,MgCO 3 5% fully mixed, calcined at high temperature at 1100 °C, and kept the temperature stable for 6h to form a stable molten state bioactive material;

[0051] (3) The prepared natural biological bone scaffold material is fixed with high-temperature ceramic material, and its vibration is placed in the...

Embodiment 3

[0056] The present embodiment provides a method for preparing an artificial bone repair material, comprising the following steps:

[0057] (1) Take natural pine beef bone, prepare a long strip structure of 1cm*1cm*2cm, remove blood fat and bone marrow and other components and rinse fully, and then use hydrogen peroxide ultrasonically soaked for 90min to further remove fat components, soaked in absolute ethanol for 30min to further inactivate the virus components, and then further cleaned with surfactant in water and dried, to obtain natural biological bone scaffold material backup;

[0058] (2) According to the quality score, the SiO will be 2 45%,CaCO 3 22%,Na 2 CO 3 20%,P 2 O 55%,MgCO 3 8% well mixed, calcined at high temperature at 1100 °C, and kept at a stable temperature for 6h to form a stable molten state bioactive material;

[0059] (3) The prepared natural biological bone scaffold material is fixed with high-temperature ceramic material, and its vibration is placed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com