Solar photovoltaic module trimming device

A solar photovoltaic and module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of poor safety and reliability, time-consuming and labor-intensive, manual trimming danger, etc., to achieve high safety and reliability, and improve safety. sex, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

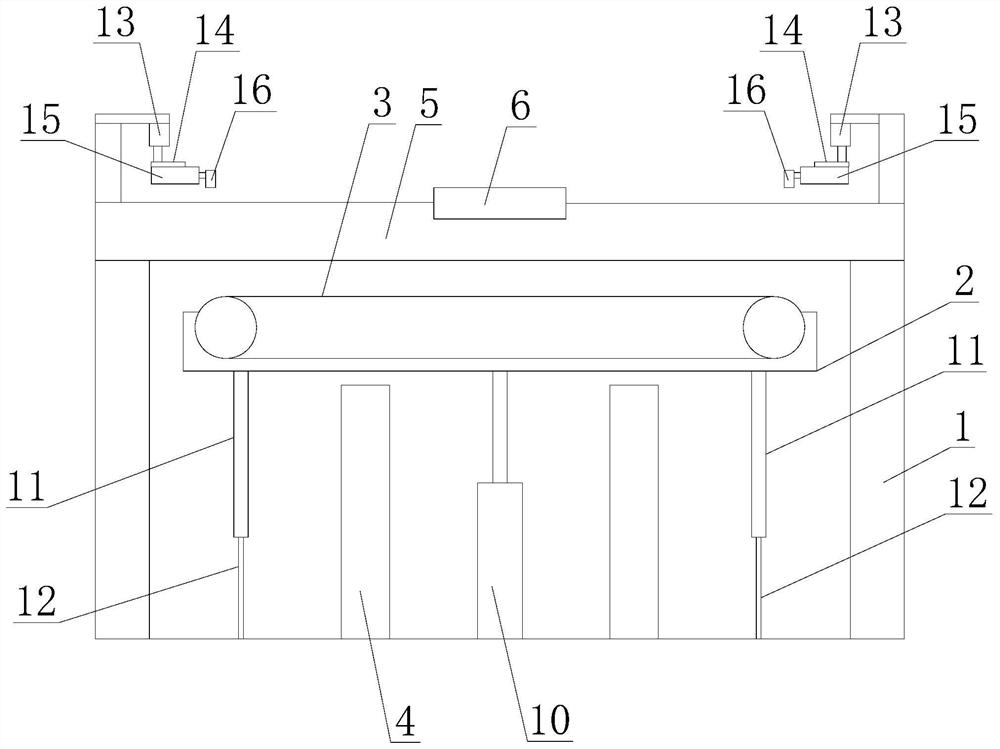

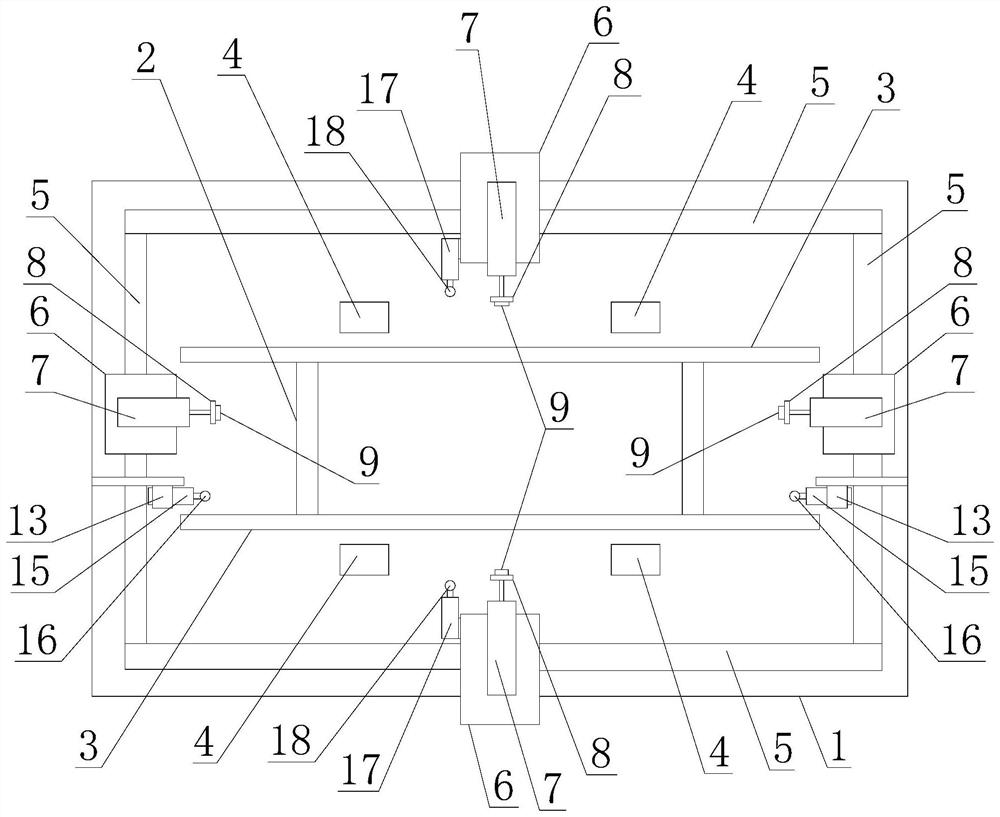

[0013] Such as figure 1 , figure 2 As shown, the described device for trimming solar photovoltaic modules includes: a frame 1, a lifting frame 2 is arranged in the frame 1, and the lifting frame 2 is set on the machine so that it can only move up and down relative to the frame 1 through a guide assembly. In the frame 1, the lifting frame 2 moves up and down in the frame 1 under the drive of the lifting drive mechanism. Several conveyor belts 3 are arranged in the lifting frame 2, and all the conveyor belts 3 together form a solar photovoltaic module capable of carrying and transporting laminated There are several support seats 4 arranged in the frame 1 on both sides of the lifting frame 2, and the upper end surfaces of all the supporting seats 4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap