Propeller pitch three-dimensional measurement process method

A process method and three-dimensional measurement technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of cumbersome measurement steps, poor measurement accuracy, and increased ship repair costs, so as to achieve convenient measurement process, improve work efficiency, The effect of shortening the repair cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

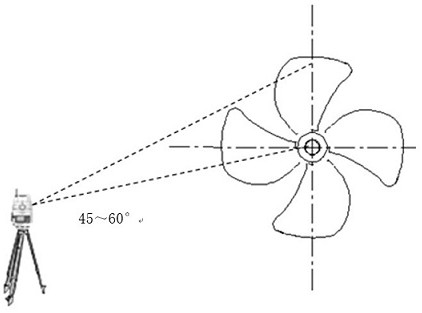

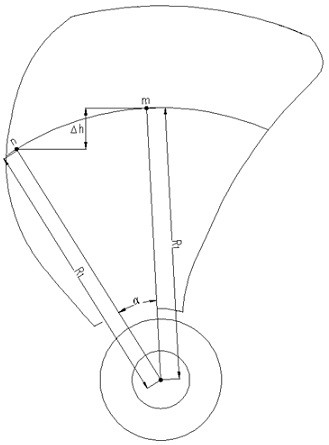

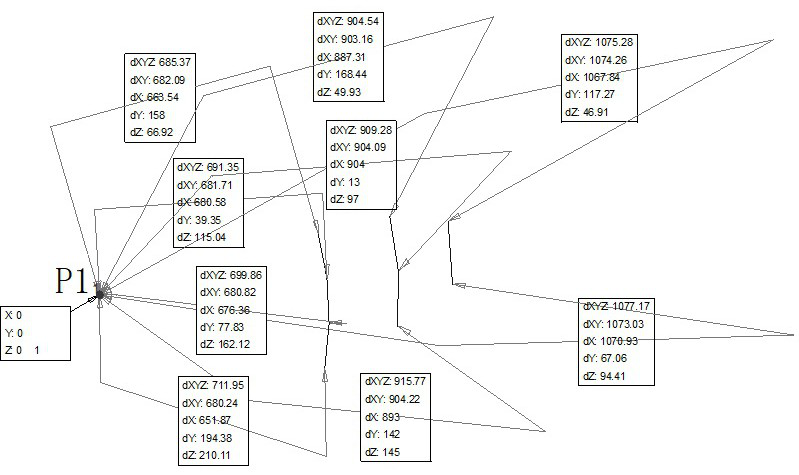

[0026] like figure 1 and figure 2 As shown in the figure, the three-dimensional measurement method of the propeller pitch specifically includes the following steps:

[0027] A. Draw a straight line with a length of at least 5m on the platform; B. Place the propeller vertically in the center area of the line to ensure that the cross section of the propeller and the contact surface of the platform are completely fitted; C. Use pitch planning to draw out each Radiate angles at different radii of the blades, and mark them with a marker; D. Set up a total station, collect the head and tail points of the line that has been scouted to establish a space coordinate system, and set the ranging mode to reflector mode during the pitch measurement process; E . Using the three-point method of generating the center of the circle, measure the space position of the center of the upper end face of the propeller blade as the pitch measurement benchmark; F. Paste the reflector at the measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com