Production method of western-style fermented ham

A production method and technology of ham, applied in the direction of dry preservation of meat/fish, food science, etc., can solve the problems of high salt content, long production cycle, etc., to solve the problems of high salt content, prevent spoilage and increase freshness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of production method of Western-style fermented ham

[0029] 1. Raw material pretreatment

[0030] Pork ham pretreatment

[0031] Landrace pigs that have grown for more than 9 months and weigh more than 150kg are selected as raw material pigs. During this period, the water content in the muscles of pigs is less, and pigs with more muscle water content will absorb more salt during the salt feeding stage. This increases the salt content of the ham, which is not conducive to the formation of the unique flavor of Western-style fermented ham. After the raw pigs are slaughtered in the company's slaughtering workshop, they are cooled and discharged for 24 hours, and then divided and trimmed. The hind legs of the pigs are taken, and the hind legs of the pigs are trimmed into "chicken thighs" and finally put into the refrigerator for later use. The storage and transportation temperature of raw materials is controlled at 0-4°C. The supplied products must e...

Embodiment 2

[0059] Embodiment 2: The process batch number of Embodiment 1 is used to inspect the ham products that leave the factory in 20190106

[0060] The products were tested for fatty acids, vitamins and amino acids, and the results are shown in Tables 2 to 4.

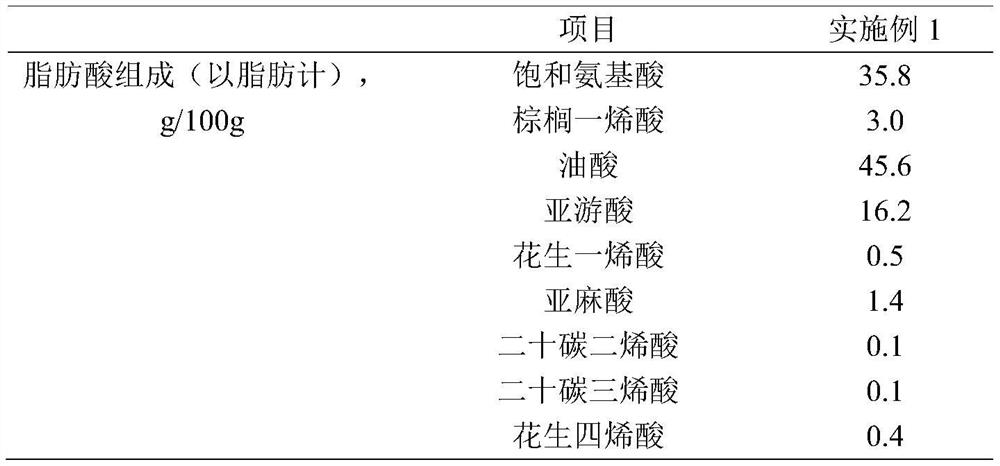

[0061] Table 2 The fermented ham fatty acid content data that the embodiment of the present invention 1 prepares

[0062]

[0063] Table 3 The fermented ham vitamin and mineral content data that the embodiment of the present invention prepares

[0064]

[0065] Table 4 Fermented ham protein and amino acid content data prepared by Example 1 of the present invention

[0066]

[0067] After sensory inspection, the ham has a fresh aroma, has the unique aroma of fermented ham, has no peculiar smell, and meets the sensory requirements of the product. The product has passed the factory inspection, among which the salt content is 9g / 100g, the water content is 50%, the peroxide value (calculated as fat) is 0.15g / 100g, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com