Rotary cleaning type mounting frame for livestock lick blocks

A technology for installing racks and licking bricks, which is applied to the cleaning method using tools, cleaning methods and utensils, animal husbandry, etc., which can solve the problems of inconvenience, waste of licking, and inability to eat evenly by licking bricks, so as to maintain flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

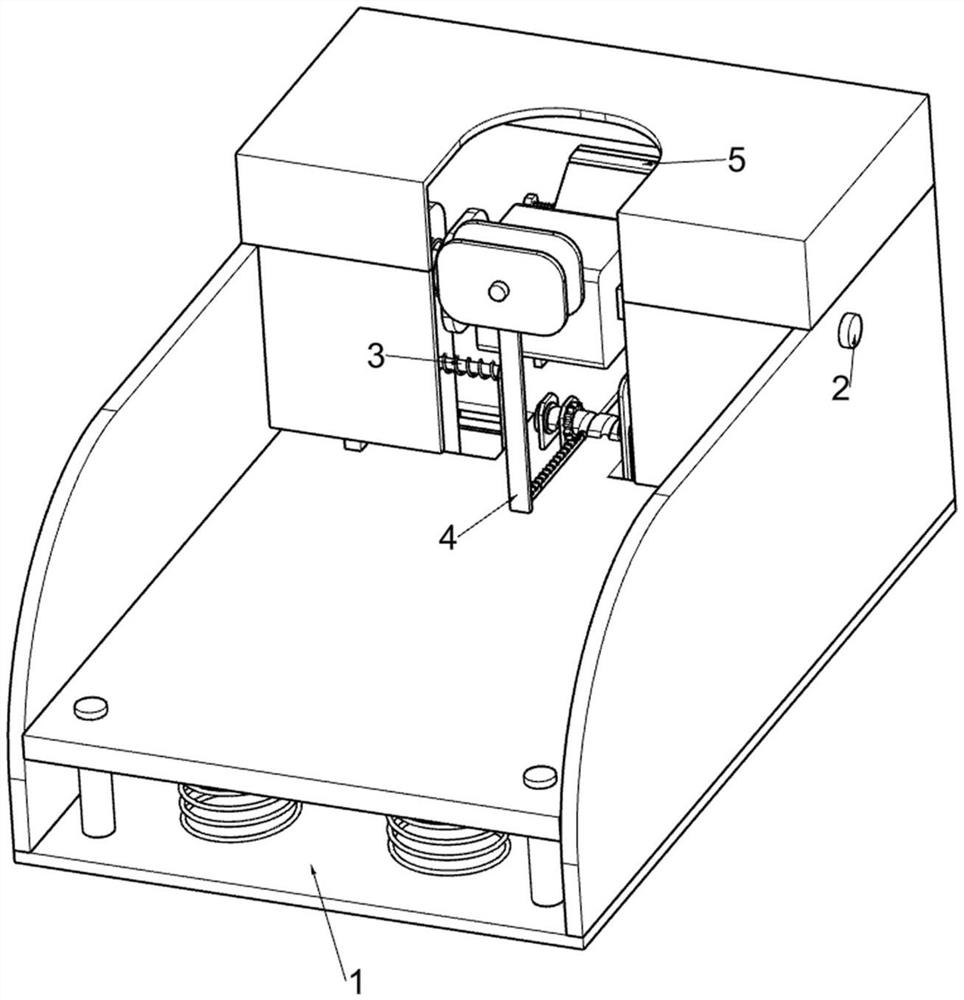

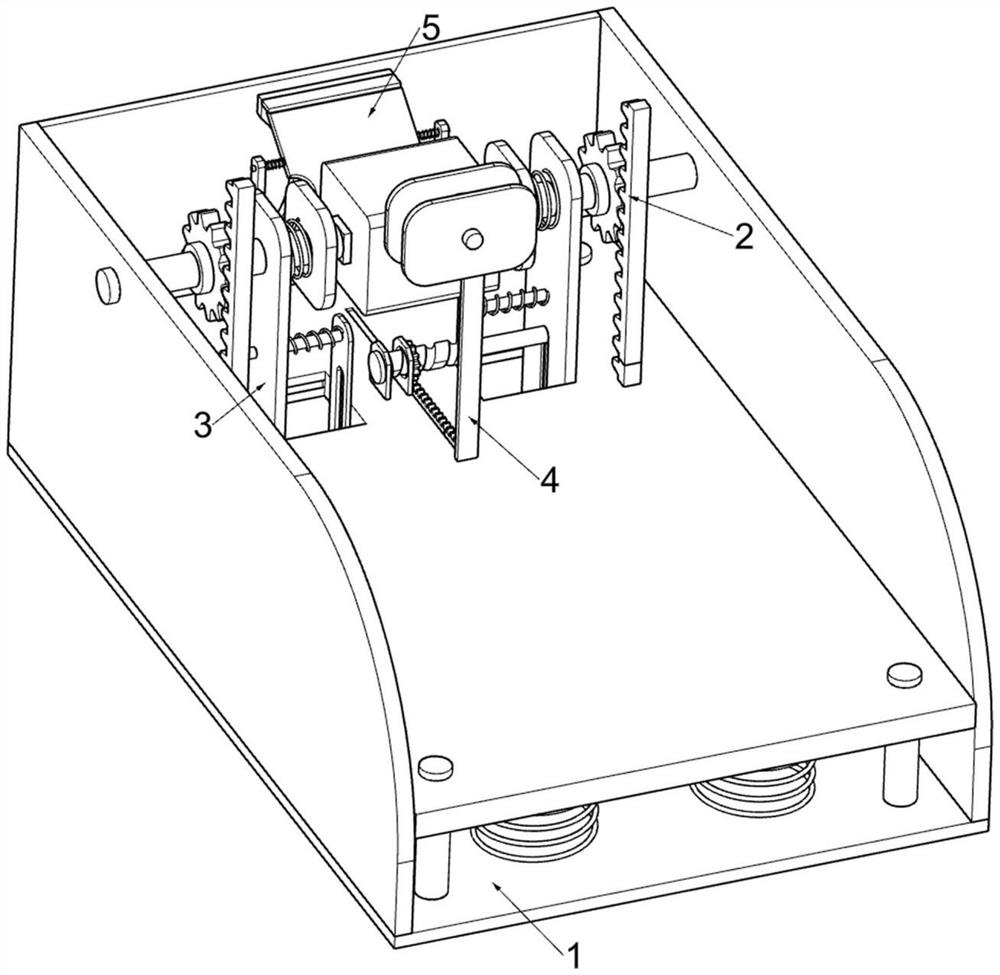

[0026] A swivel cleaning mount for livestock licking bricks, such as Figure 1-2 As shown, it includes a first support frame 1, a rotating mechanism 2, a left and right clamping mechanism 3, a front fixing mechanism 4 and a scraping mechanism 5. The first supporting frame 1 is symmetrically provided with a rotating mechanism 2, and the rotating mechanism 2 is used for To turn the licking brick over, the first support frame 1 is symmetrically provided with a left and right clamping mechanism 3, which is used to clamp both sides of the licking brick, and one side of the rotating mechanism 2 is provided with a front The other side of the fixing mechanism 4 and the rotating mechanism 2 is provided with a scraping mechanism 5, and the scraping mechanism 5 is used for scraping off bricks licked by livestock.

Embodiment 2

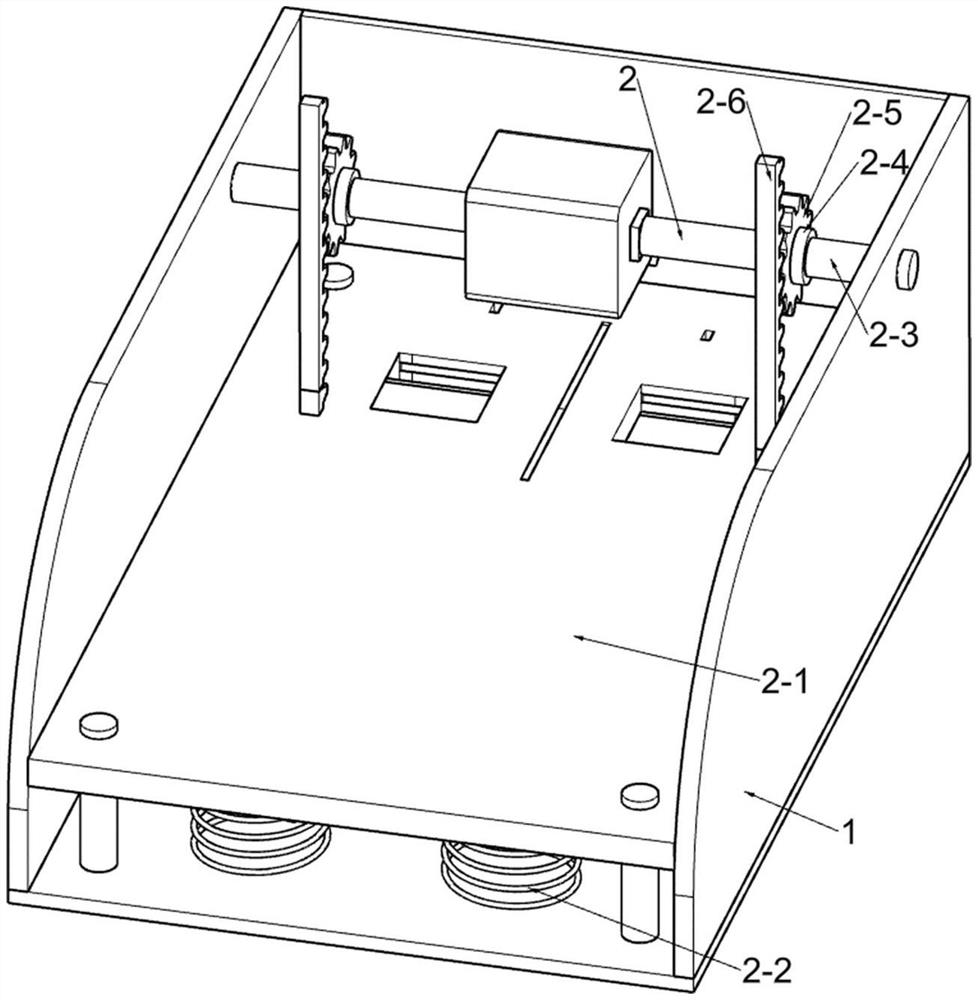

[0028] On the basis of Example 1, such as Figure 1-7 As shown, the rotating mechanism 2 includes pedals 2-1, the first spring 2-2, the first rotating shaft 2-3, the overrunning clutch 2-4, the first gear 2-5 and the transmission rack 2-6, the first A pedal 2-1 is slidably installed on the support frame 1, and the pedal 2-1 is located above the first spring 2-2. The upper end of the first spring 2-2 is fixedly connected with the pedal 2-1, and the lower end is connected with the second A support frame 1 is fixedly connected, the first support frame 1 is rotatably connected with a first rotating shaft 2-3, the first rotating shaft 2-3 is located above the pedal 2-1, and the first rotating shaft 2-3 is fixed An overrunning clutch 2-4 is installed, and the overrunning clutch 2-4 is fixedly connected with a first gear 2-5, and the pedal 2-1 is welded with a transmission rack 2-6, and the first gear 2-5 and the transmission rack 2 -6 is engaged so that the first rotating shaft 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com