Non-stop drilling slag protection blasting cartridge used outside drill rod in sleeving mode

A technology of blasting barrels and drill pipes, which is applied in the field of blasting and can solve problems such as reduced blasting effects and reduced reaction forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

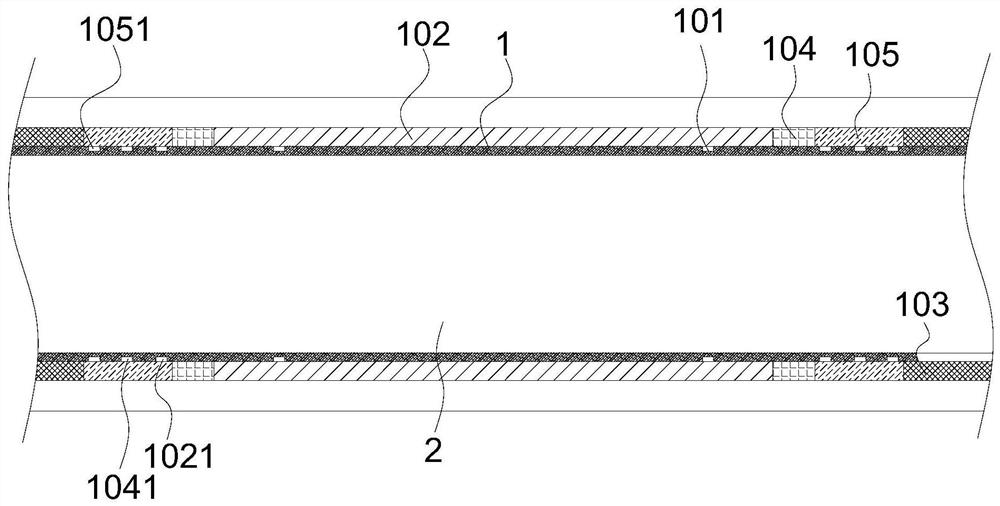

[0032] Please refer to figure 1 with figure 2 , figure 1 Shown is a schematic diagram of the cross-sectional structure of the blasting cylinder of the embodiment of the present invention; figure 2 Shown is a schematic diagram of the side view structure of the blasting cartridge body 1 according to the embodiment of the present invention.

[0033] This embodiment provides a non-stop drilling and slag protection blasting cylinder used outside the drill pipe, which includes a blasting cylinder body 1 and an ignition and detonation device 101 arranged in the blasting cylinder body 1. The blasting cylinder body 1 and the rock wall are filled with ignition and detonation devices. The explosive 102 connected to the device 101 is provided with a sealing assembly on both sides of the explosive 102 along the length direction of the blasting cartridge body 1 . The blasting cylinder body 1 is sleeved on the drill pipe 2, and fixed with the drill pipe 2 into a borehole at a certain de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com