Detection sampling device for mining

A sampling device and mining technology, applied in the direction of sampling devices, etc., can solve the problems of inability to quickly carry out mineral sampling at different depths, low degree of automation, time-consuming and laborious work, etc., achieve good economic benefits and practical significance, reasonable device structure layout, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

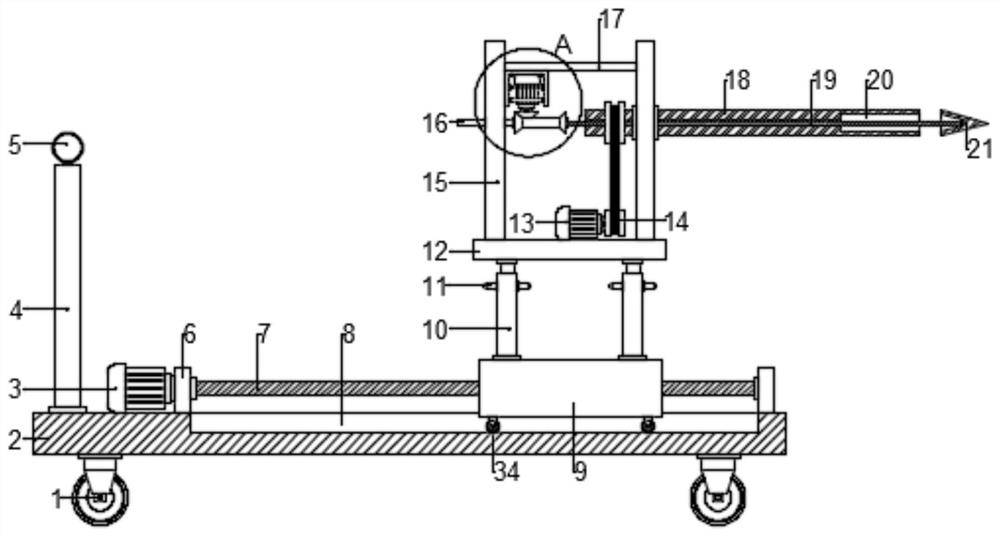

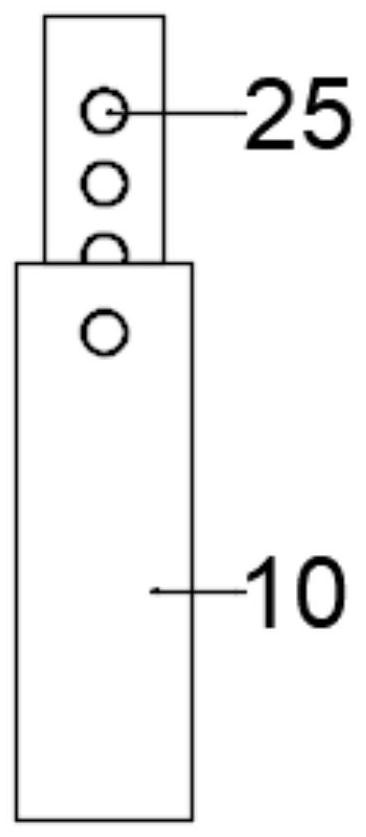

[0023] see Figure 1-5 , in an embodiment of the present invention, a detection and sampling device for mine development, including a base 2, the base 2 is provided with a chute 8 and two rectangular plates 6 are symmetrically arranged, and the two rectangular plates 6 are rotated by bearings Drive threaded rod 7 is installed, thread on the drive threaded rod 7 is provided with movable seat 9, the width of movable seat 9 is the same as the width of chute 8, and the lower end of movable seat 9 slides and is stuck in chute 8, and the bottom of movable seat 9 is symmetrically arranged. There are a plurality of guide wheels 34, and the first drive motor 3 is fixedly installed on the base 2. The first drive motor 3 is a forward and reverse motor and its output shaft is connected with one end of the drive threaded rod 7, and the drive is driven by the first drive motor 3. The threaded rod 7 rotates so that the movable seat 9 slides along the chute 8, the movable seat 9 is provided w...

Embodiment 2

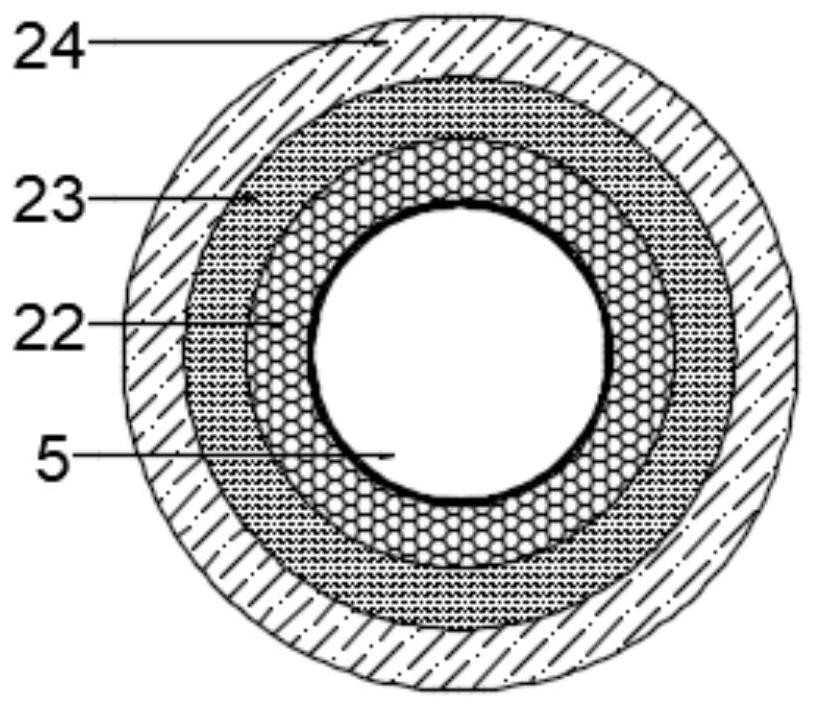

[0028] Further, the bottom of the base 2 is symmetrically provided with a plurality of rollers 1 that are convenient for moving the device. The rollers 1 are self-locking rollers. A push rod 5 for pushing the device as a whole is fixedly installed. Since the mine roads are mostly uneven, in order to prevent the staff from pushing the device to move, the bumpy feeling will be transmitted to the human body and cause sore arms. The shock-absorbing sleeve is provided with the shock-absorbing sleeve, and the shock-absorbing sleeve is composed of a shock-absorbing foam layer 22, a shock-absorbing particle layer 23 and a rubber layer 24 in sequence from the inside to the outside.

[0029]The working principle of the present invention is: when the present invention is in use, the device is first pushed to the edge of the sampling point, then the length of the height adjustment rod 10 is adjusted so that the height of the sampling cylinder 18 is kept level with the height of the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com